Tobacco style leaf composition used for cigarette realizing various heating modes, cigarette realizing various heating modes, and preparation method of cigarette realizing various heating modes

A heating method and composition technology, applied in the direction of tobacco, tobacco processing, application, etc., can solve the problem that the overall flavor of the product cannot meet people's requirements, and achieve the effect of unique tobacco style flavor and flavor improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

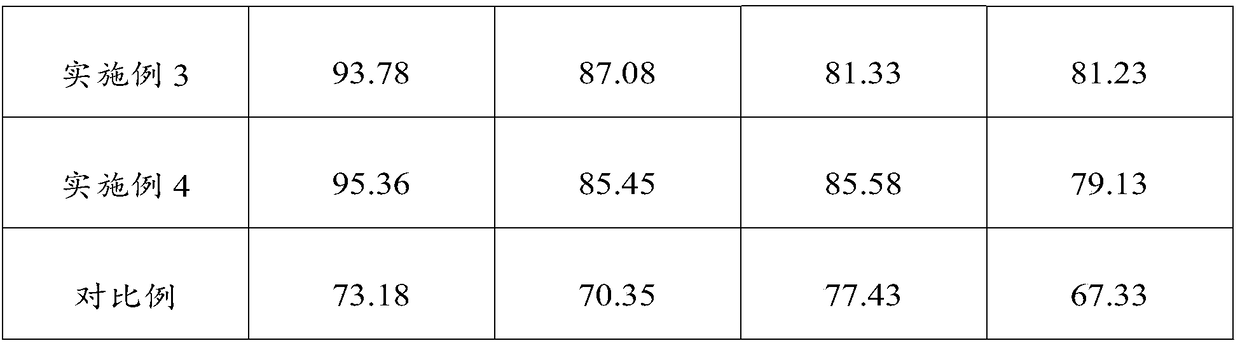

Examples

preparation example Construction

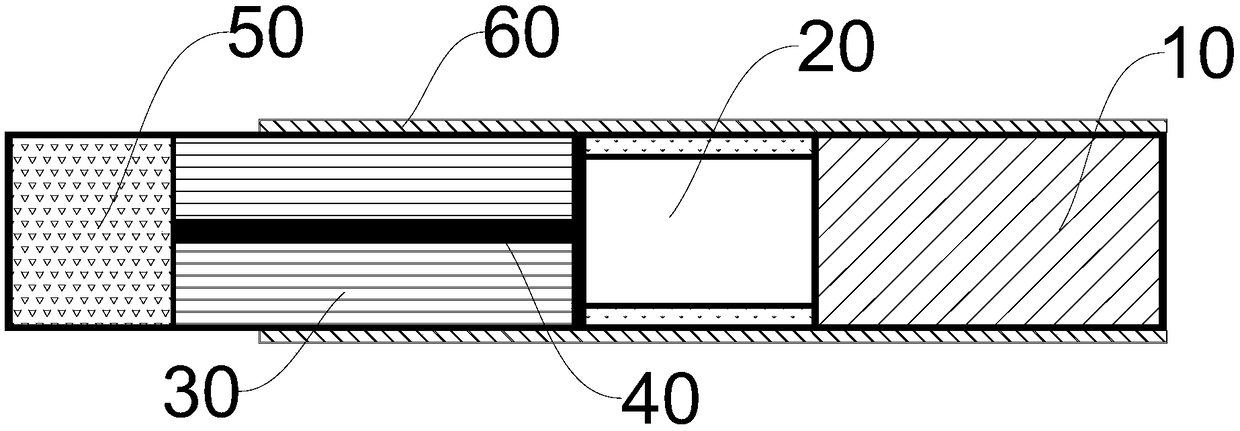

[0034] Embodiments of the present invention also provide a method for preparing cigarettes with multiple heating methods, comprising the following steps:

[0035] S1. Processing and uniformly mixing the above-mentioned filling and flavoring module, taste module, flavoring module and smoking module to obtain the above-mentioned tobacco-style leaf composition for various heating methods of cigarettes;

[0036]S2. After storing the above-mentioned tobacco-style leaf composition for cigarettes with various heating methods through the cigarette shredding process for 12-24 hours, a mouthless cigarette with a disordered structure is obtained through a cigarette machine;

[0037] S3. Making the above-mentioned mouthless cigarettes with disordered structure into a cigarette with multiple heating methods through the filter rod compounding process and the cigarette rubbing process.

[0038] Specifically, the preparation process of the above-mentioned tobacco-style leaf composition for ci...

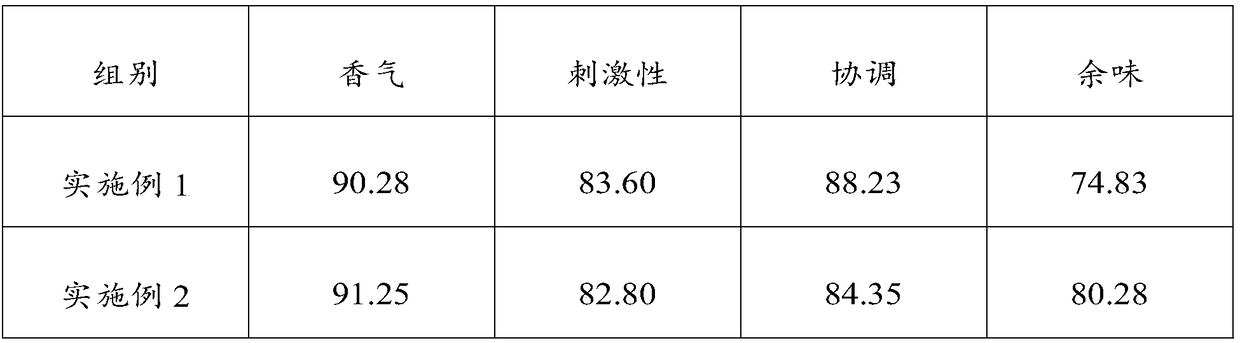

Embodiment 1

[0047] The present example provides a tobacco-style leaf composition for cigarettes with various heating methods. In parts by weight, the composition includes 30 parts of filling and flavoring modules, 2 parts of mouthfeel modules, and 20 parts of flavoring modules And 5 parts of the smoking module; among them, the filling and flavoring module includes 20 parts of expanded shredded tobacco and 10 parts of cut stem; the taste module includes 0.5 parts of apple, 0.5 part of passion fruit, 0.5 part of hawthorn and 0.5 part of lily; the flavoring module includes spices 8 parts of tobacco, 6 parts of burley tobacco, 4 parts of air-cured tobacco and 2 parts of cigar; the smoking module includes 2.5 parts of glycerin, 2 parts of propylene glycol and 0.5 part of sorbitol.

[0048] This embodiment also provides a method for preparing cigarettes with multiple heating methods, which includes the following steps:

[0049] (1) each module component in the above-mentioned composition is mad...

Embodiment 2

[0054] The present example provides a tobacco-style leaf composition for cigarettes with various heating methods. In parts by weight, the above-mentioned composition includes 50 parts of filling and flavoring modules, 7 parts of taste modules, and 40 parts of flavoring modules. And 15 parts of the smoking module; among them, the filling and flavoring module includes 30 parts of expanded shredded tobacco and 20 parts of shredded stems; the taste module includes 2 parts of apple, 1 part of cumin, 2 parts of hawthorn and 2 parts of honey; the flavoring module includes spices 15 parts of tobacco, 15 parts of burley tobacco and 10 parts of cigar; the smoking module includes 5 parts of glycerin, 5 parts of propylene glycol and 5 parts of sorbitol.

[0055] This embodiment also provides a method for preparing cigarettes with multiple heating methods, which includes the following steps:

[0056] (1) each module component in the above-mentioned composition is made above-mentioned each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com