Testing method for de-boron rate of coiled brackish water reverse osmosis membrane element

A reverse osmosis membrane and testing method technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of deviation from the actual application conditions of brackish water reverse osmosis membrane elements, and the lack of reliability of the boron removal rate test method Sexuality and scientificity, test results do not match the actual application performance, etc., to achieve the effect of easy promotion, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

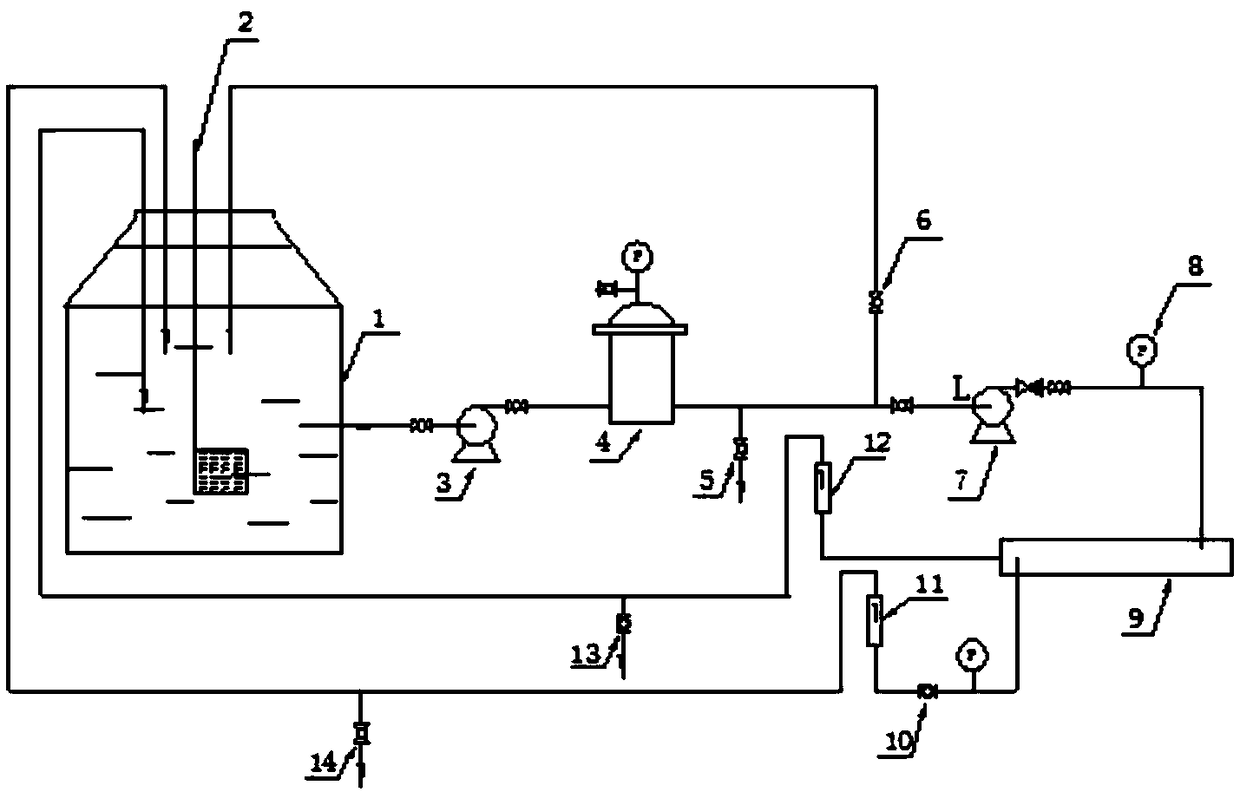

Embodiment 1

[0026] Rinse the BW30-8040 brackish water reverse osmosis membrane element produced by Dow Company of the United States with deionized water or distilled water with a flow rate of 5L / h for 5 minutes at room temperature; use it in the water tank of the reverse osmosis membrane element permeability test device Prepare 1500mg / L sodium chloride solution with deionized water, then add boric acid to make the boron concentration reach 2mg / L, adjust the pH value of the solution to 6.5 with sodium hydroxide; put the washed brackish water reverse osmosis membrane element into the membrane shell In the middle, the concentrated water regulating valve is fully open, turn on the water supply pump, make the system run at low pressure for 3 minutes, and discharge the air in the system; turn on the energy recovery of the test device in turn, and the high pressure pump to boost the inlet water pressure to 1.5MPa, The recovery rate is 14%, the temperature of the test solution is adjusted to 24 ° ...

Embodiment 2

[0031]Rinse the BW30-8040 brackish water reverse osmosis membrane element produced by American Dow Company with deionized water or distilled water with a flow rate of 6.5L / h for 7.5 minutes at room temperature; put it in the water tank of the reverse osmosis membrane element permeability test device Prepare 1750mg / L sodium chloride solution with deionized water, then add boric acid to make the boron concentration reach 2.5mg / L, adjust the pH value of the solution to 7 with sodium hydroxide; put the brackish water reverse osmosis membrane element after washing into In the membrane shell, the concentrated water regulating valve is fully open, and the water supply pump is turned on to make the system run at low pressure for 4 minutes to discharge the air in the system; turn on the energy recovery of the test device in turn, and the high pressure pump to boost the inlet water pressure to 2MPa , the recovery rate is 15%, the temperature of the test solution is adjusted to 25°C, and ...

Embodiment 3

[0036] Rinse the BW30-8040 brackish water reverse osmosis membrane element produced by Dow Company of the United States with deionized water or distilled water with a flow rate of 8L / h for 10 minutes at room temperature; use it in the water tank of the reverse osmosis membrane element permeability test device Prepare 2000mg / L sodium chloride solution with deionized water, then add boric acid to make the boron concentration reach 3mg / L, adjust the pH value of the solution to 7.5 with sodium hydroxide; put the washed brackish water reverse osmosis membrane element into the membrane shell In the middle, the concentrated water regulating valve is fully open, and the water supply pump is turned on to make the system run at low pressure for 5 minutes, and the air in the system is discharged; the energy recovery of the test device is turned on in turn, and the high-pressure pump boosts the inlet water pressure to 2.5MPa. The recovery rate is 16%, the temperature of the test solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com