Panel seawater reverse osmosis membrane boron removal rate testing method

A technology of reverse osmosis membranes and testing methods, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the deviation from the actual application conditions of seawater reverse osmosis membranes, lack of comparability of different reverse osmosis membranes, and few Pay attention to the impact of test conditions and other issues to achieve the effect of easy promotion, improved repeatability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

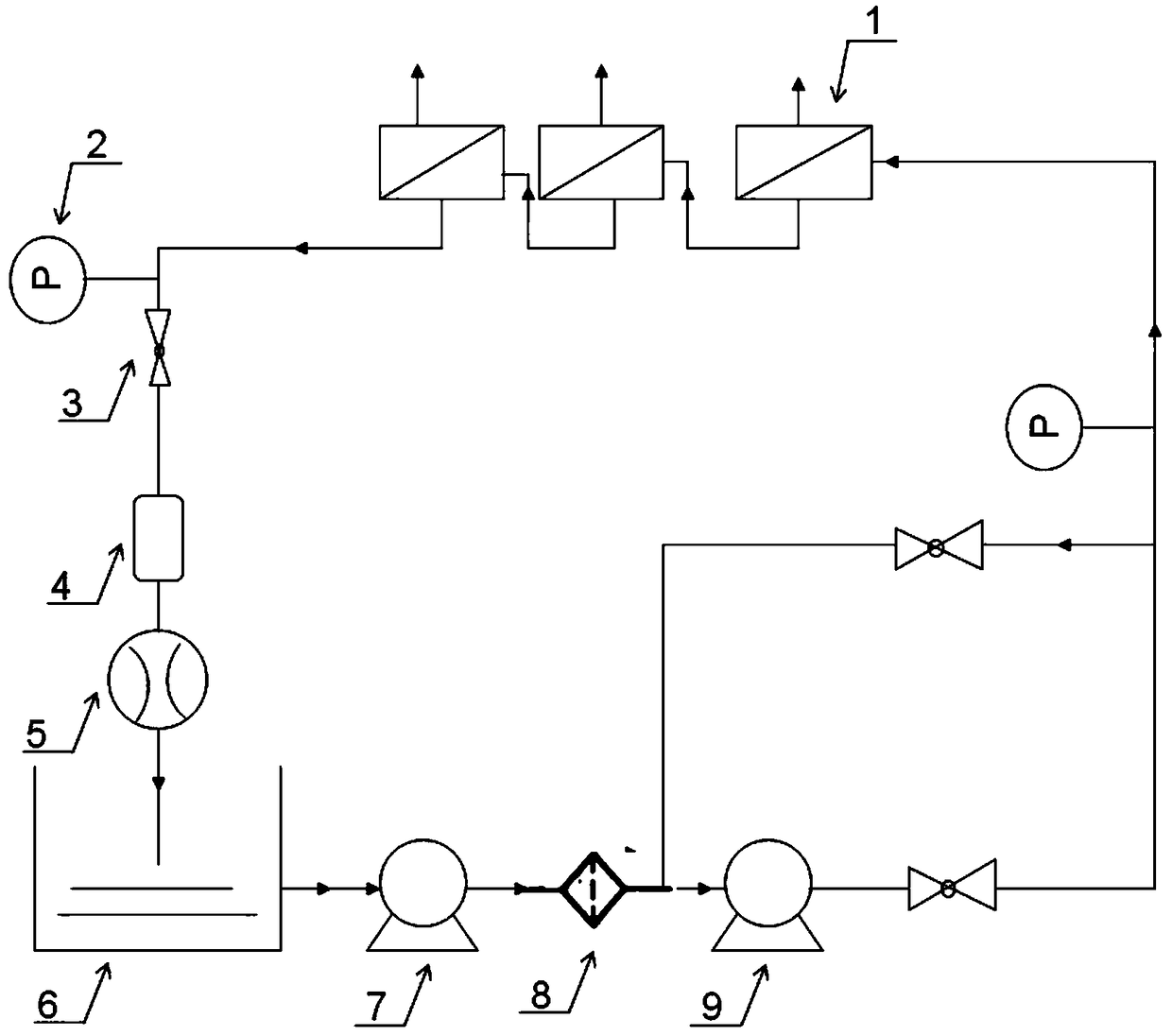

Method used

Image

Examples

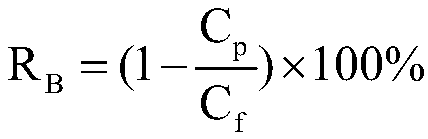

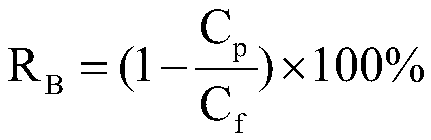

Embodiment 1

[0028] Cut a piece of membrane without obvious defects such as wrinkles and breakages from the TM800K seawater reverse osmosis membrane produced by Toray Corporation in Japan. The size of the membrane completely covers the sealing ring of the reverse osmosis membrane test pool, and the effective membrane area is 25cm 2 , Soak the diaphragm in deionized water or distilled water for 30 minutes at room temperature; use deionized water to prepare 30000mg / L sodium chloride solution in the water tank of the reverse osmosis membrane test device, and then add boric acid to make the boron concentration reach 5mg / L, the pH value of the solution was adjusted to 7.5 with sodium hydroxide; put the soaked seawater reverse osmosis membrane into the test tank, the membrane separation layer should face the water inlet side of the test tank; turn on the reverse osmosis membrane test device in turn Raw water pump and high-pressure pump, boost the inlet water pressure to 5MPa, the flow velocity o...

Embodiment 2

[0033] Cut a piece of membrane without obvious defects such as wrinkles and breakages from the TM800K seawater reverse osmosis membrane produced by Toray Corporation in Japan. The size of the membrane completely covers the sealing ring of the reverse osmosis membrane test pool, and the effective membrane area is 33cm 2, Soak the diaphragm in deionized water or distilled water for 45 minutes at room temperature; use deionized water to prepare a 32000mg / L sodium chloride solution in the water tank of the reverse osmosis membrane test device, and then add boric acid to make the boron concentration reach 6.5 mg / L, the pH value of the solution was adjusted to 8 with sodium hydroxide; put the soaked seawater reverse osmosis membrane into the test tank, the membrane separation layer should face the water inlet side of the test tank; turn on the reverse osmosis membrane test device in turn Raw water pump and high-pressure pump, boost the inlet water pressure to 5.5MPa, the flow velocit...

Embodiment 3

[0038] Cut a piece of membrane without obvious defects such as wrinkles and breakages from the TM800K seawater reverse osmosis membrane produced by Toray Corporation in Japan. The size of the membrane completely covers the sealing ring of the reverse osmosis membrane test pool, and the effective membrane area is 40cm 2 , Soak the diaphragm in deionized water or distilled water for 60 minutes at room temperature; prepare 34000mg / L sodium chloride solution with deionized water in the water tank of the reverse osmosis membrane test device, and then add boric acid to make the boron concentration reach 8mg / L, the pH value of the solution was adjusted to 8.5 with sodium hydroxide; put the soaked seawater reverse osmosis membrane into the test tank, the membrane separation layer should face the water inlet side of the test tank; turn on the reverse osmosis membrane test device in turn Raw water pump and high pressure pump, boost the inlet water pressure to 6MPa, the surface flow velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com