High-efficiency industrial mixing apparatus for liquid chemical raw materials

A technology of chemical raw materials and mixing devices, which is applied in the direction of mixers, shaking/oscillating/vibrating mixers, transportation and packaging, etc., which can solve the problems of uneven mixing of raw materials, poor mixing of finished products, and insufficient mixing of raw materials Expected requirements and other issues to achieve the effect of improving the mixing purity, improving the effect, and increasing the speed of filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

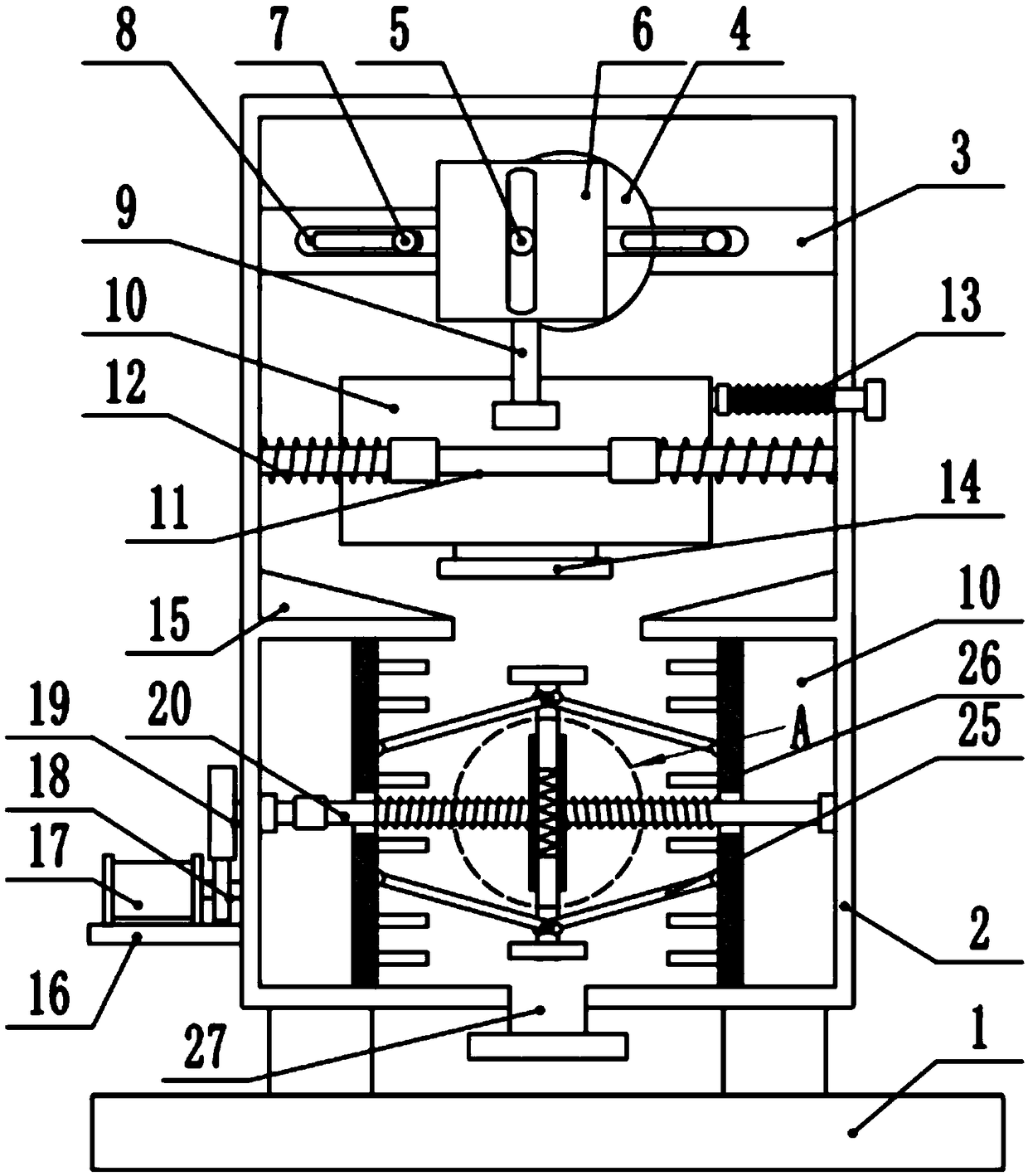

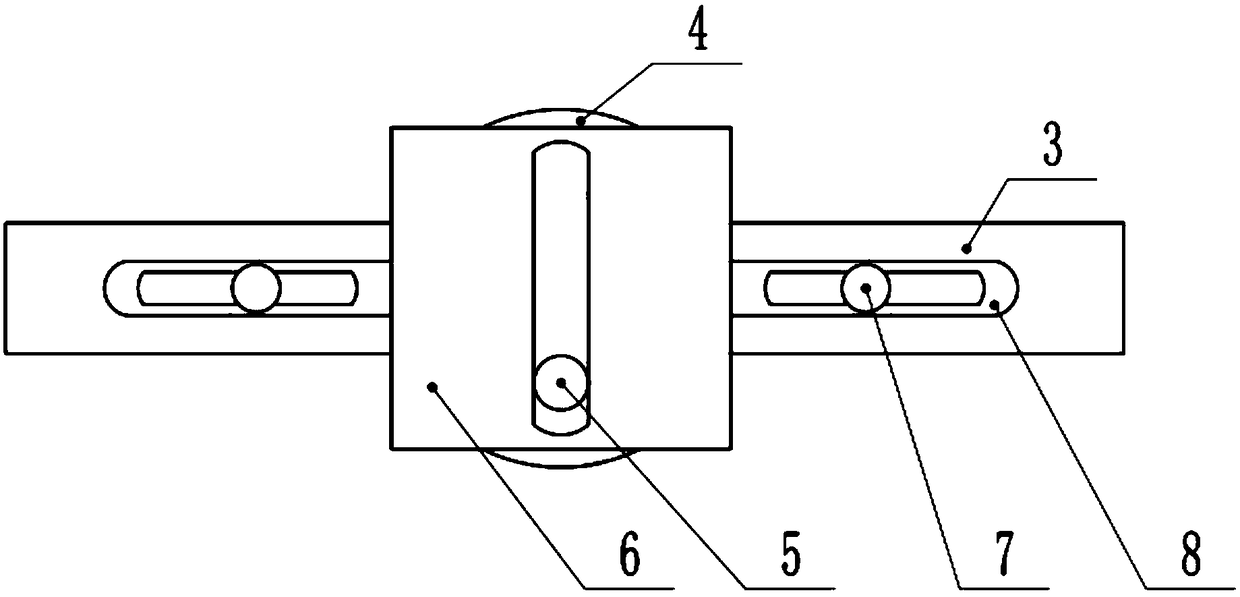

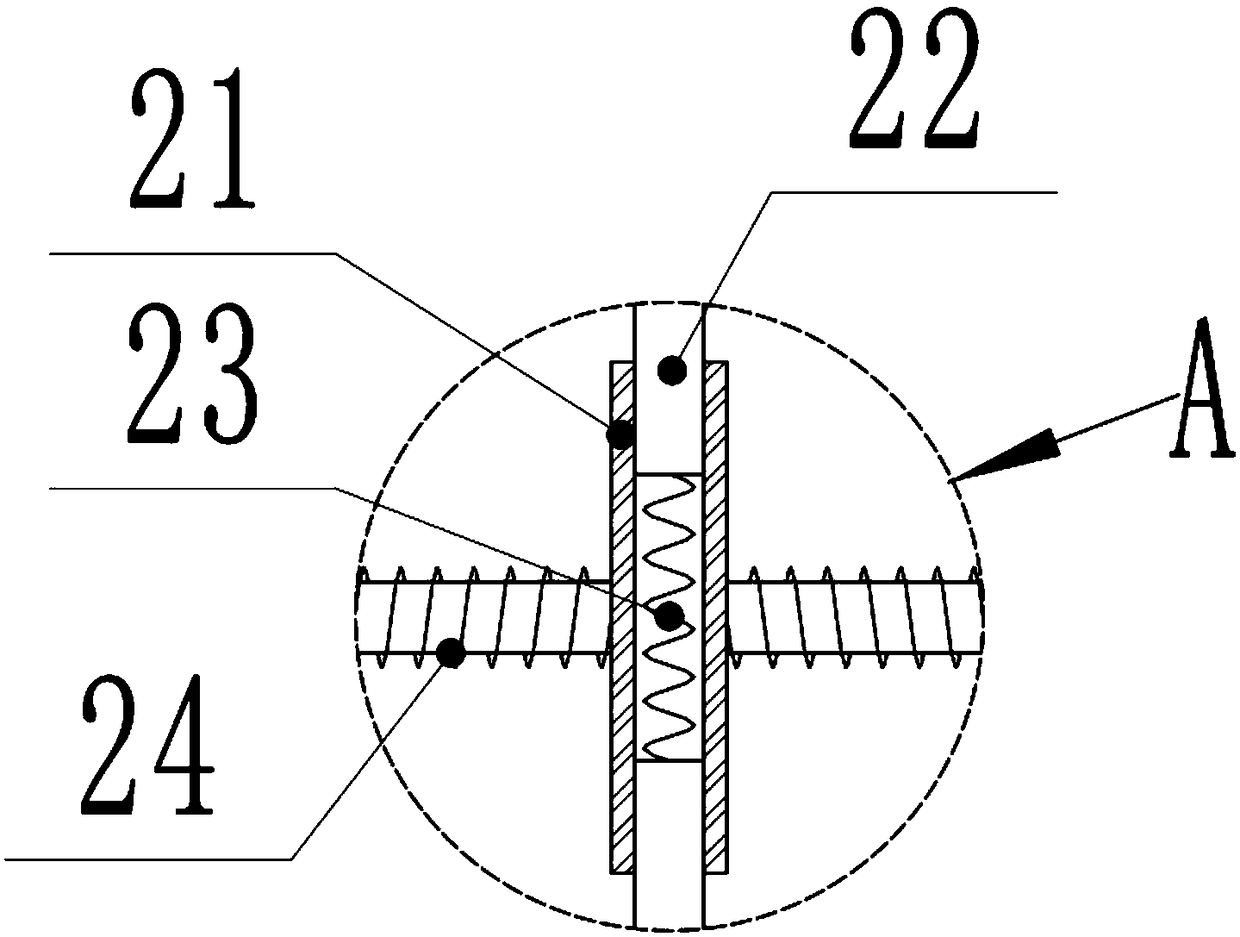

[0018] see figure 1 and figure 2 , a high-efficiency mixing device for industrial liquid chemical raw materials, comprising a base 1, a mixing box 2, a filter box 10 and a liquid disturbance plate 26, the base 1 is provided with a mixing box 2, and the mixing box 2 and the base 1 are connected with Support feet, a fixed frame 3 is welded horizontally between the inner walls of the left and right sides of the mixing box 2, and a drive motor (not marked in the figure) is fixedly installed on the fixed frame 3, the output shaft of the drive motor is forward and the output shaft of the drive motor The upper interference fit is equipped with a runner 4, the surface of the runner 4 is interference fitted with a connecting shaft 5, the connecting shaft 5 is perpendicular to the surface of the runner 4, the connecting shaft 5 is provided with a slider 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com