Novel hot-dip galvanizing pot

A new type of hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of inconvenient removal, power loss, thermal conversion rate reduction, etc., to achieve low maintenance costs , good heating effect, easy to salvage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

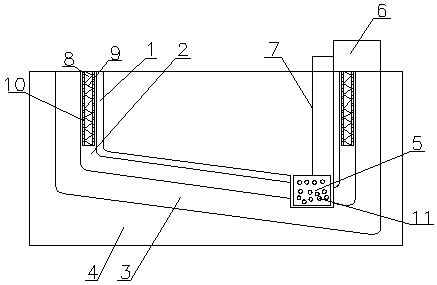

[0013] A new type of hot-dip galvanized pot, comprising a zinc pot body 1, a heating layer 2, an insulation layer 3 and a protective layer 4, the inner bottom surface of the zinc pot body 1 is an inclined plane, and a slag collection pit is provided at the bottom of the inclined plane, and the heating Layer 2 is arranged on the outer side of the zinc pot body 1, the thermal insulation layer 3 is arranged on the outer side of the heating layer 2, the protective layer 4 is arranged on the outer side of the thermal insulation layer 3, a slag collection tank 5 is placed in the slag collection pit, and the zinc pot The upper end of the main body 1 is provided with a lifting mechanism 6 , and the slag collection tank 5 is connected with the lifting mechanism 6 through a connecting rod 7 .

[0014] As a further improvement of the above technical solution, the zinc pot body 1 is composed of refractory ceramic bricks.

[0015] As a further improvement of the above technical solution, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com