Production task distribution pulling system and method

A production task and mobile vehicle technology, applied in the general control system, control/adjustment system, comprehensive factory control, etc., can solve the problems of serious waste of process waiting, occupation of raw materials and funds, and impact on product delivery time, so as to save raw materials Consumption, production cycle shortening, and the effect of saving capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

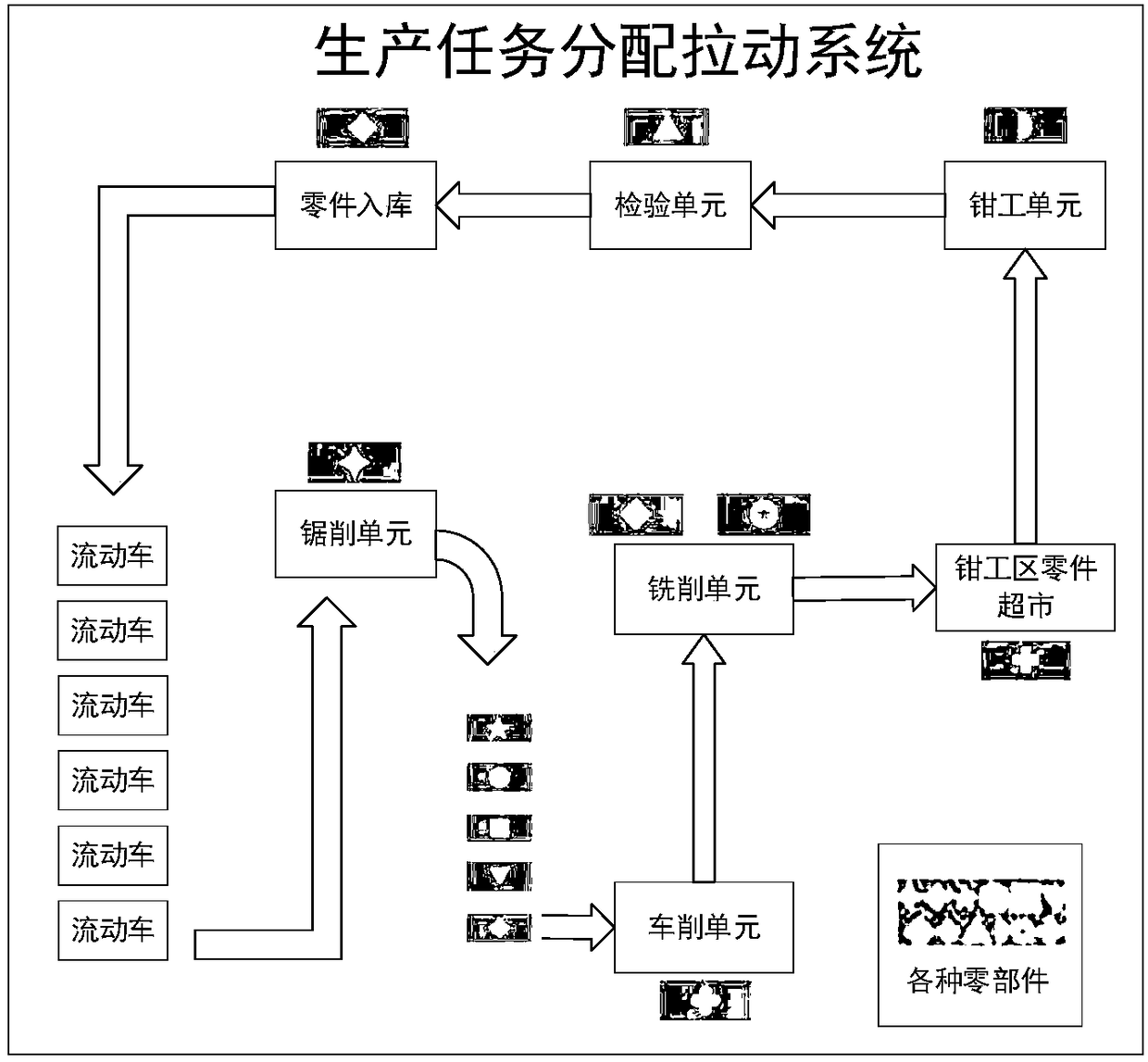

[0037] Design a "production task allocation pulling system" according to the principle of lean production. This system arranges the production tasks according to the pull allocation method, so that many problems caused by the original single piece / small batch production method can be avoided, waste can be reduced, efficiency can be improved, and production costs can be reduced. Such as figure 1 As shown, the processing cycle of the system is less than 1 week, with an average of 3 days.

[0038] The design scheme of "Production Task Assignment Pulling System" is as follows:

[0039] 1. Design a special "production task assignment pulling system" software to control the operation of the entire pulling production system.

[0040] 2. Production orders and parts are placed in the same mobile car. A flow vehicle is the smallest flow unit of a production flow.

[0041] 3. The maximum number of parts loaded on a mobile vehicle is limited and cannot exceed the maximum limited quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com