A kind of Hichongwei dry suspension and preparation method thereof

A technology of dry suspending agent and oxacarb, applied in the field of pesticides, can solve the problems of affecting the spray drying process and the high viscosity of the slurry, and achieve the effects of low storage and transportation cost, good dispersibility and good storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

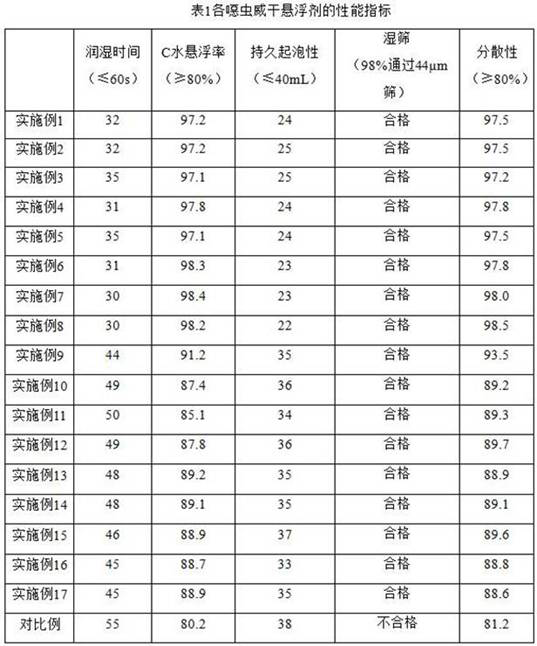

Examples

Embodiment 180

[0032] Embodiment 1 80% Diechongwei Dry Suspension Concentrate

[0033] The formula is: bentoxacarb 80%, dispersant hyperbranched polyamide ester 3.2%, alkylphenol polyoxyethylene ether succinate sulfonate 1.6%, sodium lignosulfonate 3.2%, wetting agent dodecane Sodium sulfate 1%, sodium alkylnaphthalene sulfonate 3%, disintegrant diammonium hydrogen phosphate 2%, urea 1%, defoamer organosiloxane 0.5%, filler kaolin to make up 100%.

[0034] The preparation method is as follows:

[0035] 1. Mix bentacarb, dispersant, wetting agent, disintegrant, defoamer, filler and water to obtain a slurry. The amount of water is 45-50% of the total mass of each component.

[0036] 2. Grind the uniformly mixed slurry with a sand mill until the particle size D90 is 3-5μm, then pump the suspoemulsion slurry into a pressure spray dryer for drying and granulation. The spray pressure is controlled at 3.6MPa, and the drying gas enters The air temperature is 130°C, and the outlet air temperature i...

Embodiment 2

[0037] Example 2 70% Dichrocarb Dry Suspension Concentrate

[0038]The formula is: bentoxacarb 70%, dispersant hyperbranched polyamide ester 3.2%, alkylphenol polyoxyethylene ether succinate sulfonate 1.6%, sodium lignosulfonate 3.2%, wetting agent dodecane Sodium sulfate 1%, sodium alkylnaphthalene sulfonate 3%, disintegrant diammonium hydrogen phosphate 2%, urea 1%, defoamer organosiloxane 0.5%, filler kaolin to make up 100%.

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0040] Example 3 75% Dichrocarb dry suspension

[0041] The formula is: bentoxacarb 75%, dispersant hyperbranched polyamide ester 2%, alkylphenol polyoxyethylene ether succinate sulfonate 3%, sodium lignosulfonate 2%, wetting agent dodecane Sodium sulfate 1%, sodium alkylnaphthalene sulfonate 2%, disintegrant diammonium hydrogen phosphate 4%, urea 1%, defoamer organosiloxane 0.1%, filler kaolin to make up 100%.

[0042] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com