Production method for prepared rehmannia root refined decoction pieces

A technology of refined decoction pieces and production methods, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, plant raw materials, etc., can solve problems such as backward production technology, low quality of rehmannia glutinosa pieces, and poor application effects, so as to improve efficiency, Automatic control of cleaning time and thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

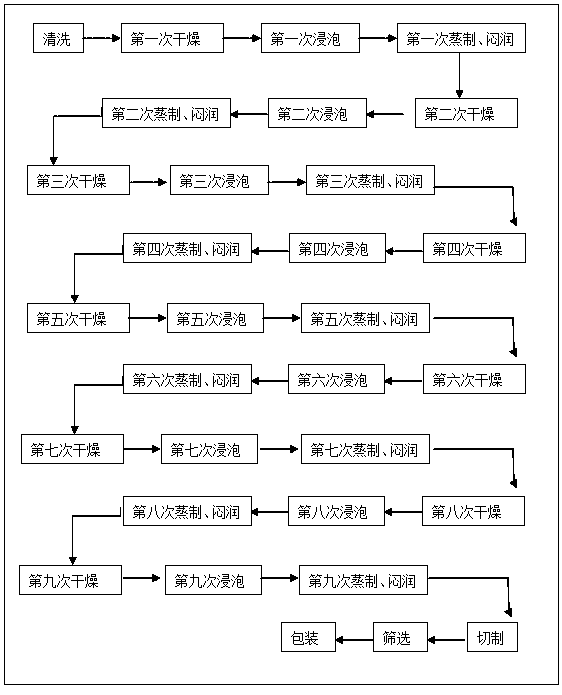

Image

Examples

Embodiment 1

[0010] The present embodiment provides a kind of production method of Rehmannia glutinosa refined decoction piece, comprises the following steps:

[0011] 1. Put the processed Rehmannia glutinosa into a stainless steel container and add water to soak for 1 hour until the surface softens, then wash it with a drum washing machine until there is no sediment on the surface to obtain clean Rehmannia glutinosa.

[0012] 2. Put the cleaned Rehmannia glutinosa into the bamboo weaving, and let it dry naturally in the sun room for 24 hours at a temperature of 80°C. Turn it over and dry it every 6 hours. After drying, the rehmannia glutinosa moisture is lower than 20%, which is convenient for follow-up Soak raw rehmannia to the heart with rice wine.

[0013] 3. Soak the dried Rehmannia glutinosa nine times, and use rice wine with an alcohol content of 12 degrees for each soak. The ratio is to use 30kg of rice wine for every 100kg of rehmannia glutinosa, soak for 12 hours, and turn over o...

Embodiment 2

[0020] The present embodiment provides a kind of production method of Rehmannia glutinosa refined decoction piece, comprises the following steps:

[0021] 1. Put the processed Rehmannia glutinosa into a stainless steel container, add water and soak for 2 hours until the surface softens, and then use a drum washing machine to clean the surface until there is no sediment on the surface to obtain clean Rehmannia glutinosa.

[0022] 2. Put the cleaned Rehmannia glutinosa into the bamboo weaving, and dry it naturally in the sun room for 36 hours at a temperature of 70°C. Turn it over and dry it every 6 hours. The moisture content of the rehmannia glutinosa after drying is less than 15%, which is convenient for follow-up Soak raw rehmannia to the heart with rice wine.

[0023] 3. Soak the dried Rehmannia glutinosa nine times, and use rice wine with an alcohol content of 12 degrees for each soak. The ratio is to use 30kg of rice wine for every 100kg of rehmannia glutinosa, soak for 1...

Embodiment 3

[0030] The present embodiment provides a kind of production method of Rehmannia glutinosa refined decoction piece, comprises the following steps:

[0031] 1. Put the processed Rehmannia glutinosa into a stainless steel container and add water to soak for 3 hours until the surface softens, and then use a drum washing machine to clean the surface until there is no sediment on the surface to obtain clean Rehmannia glutinosa.

[0032] 2. Put the cleaned Rehmannia glutinosa into the bamboo weaving, and let it dry naturally in the sunshine room for 24 hours at a temperature of 60°C. Turn it over and dry it every 6 hours. After drying, the rehmannia glutinosa moisture is lower than 10%, which is convenient for follow-up Soak raw rehmannia to the heart with rice wine.

[0033] 3. Soak the dried Rehmannia glutinosa nine times, and use rice wine with an alcohol content of 12 degrees for each soak. The ratio is 30kg of rice wine for every 100kg of Rehmannia glutinosa, soak for 10 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com