Air supply system suitable for aircraft overall paint spraying ventilation

An air supply system and overall technology, applied in spray booths, injection devices, etc., can solve problems such as large air outlet spacing, long cycle, and influence on roof structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

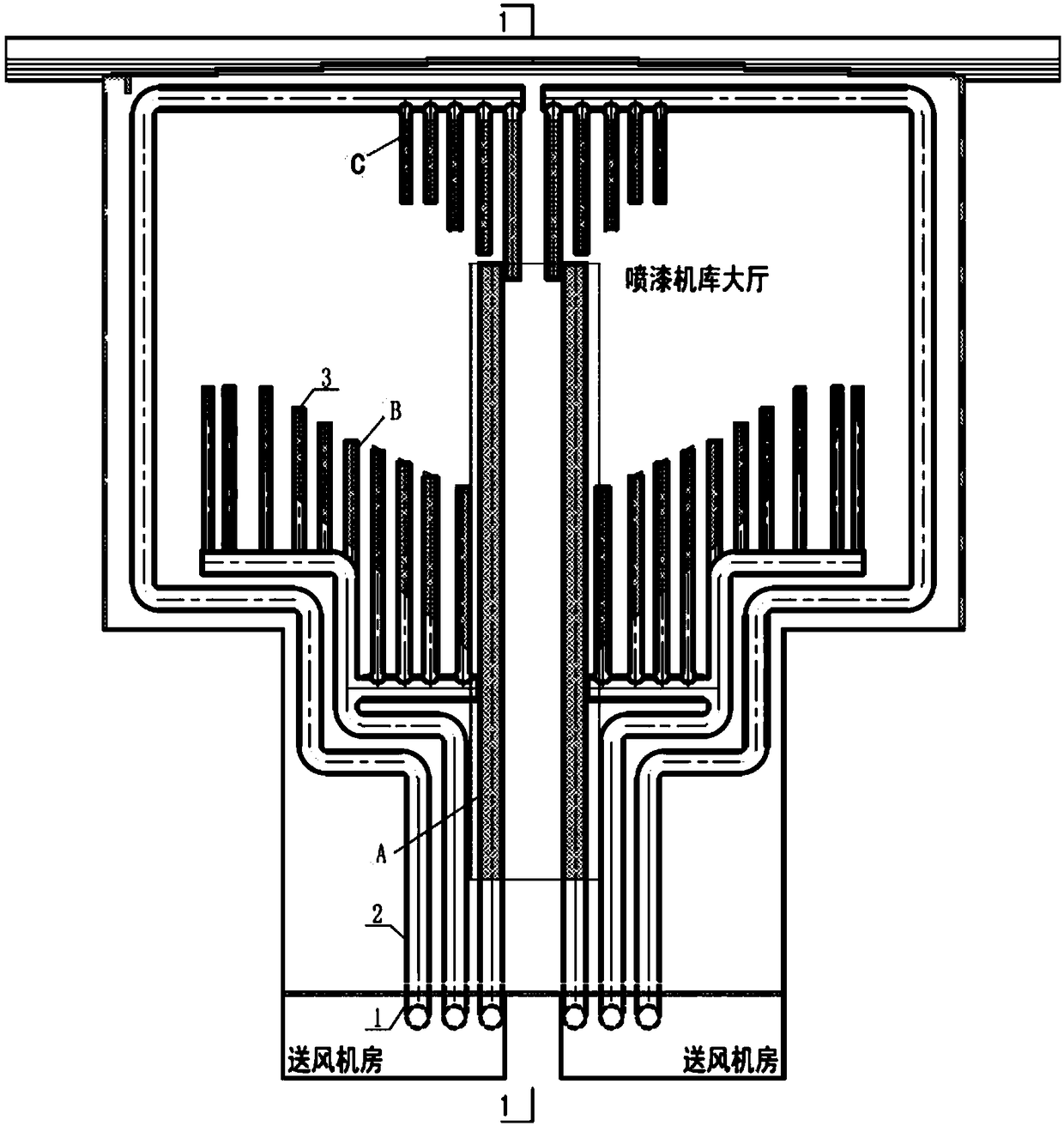

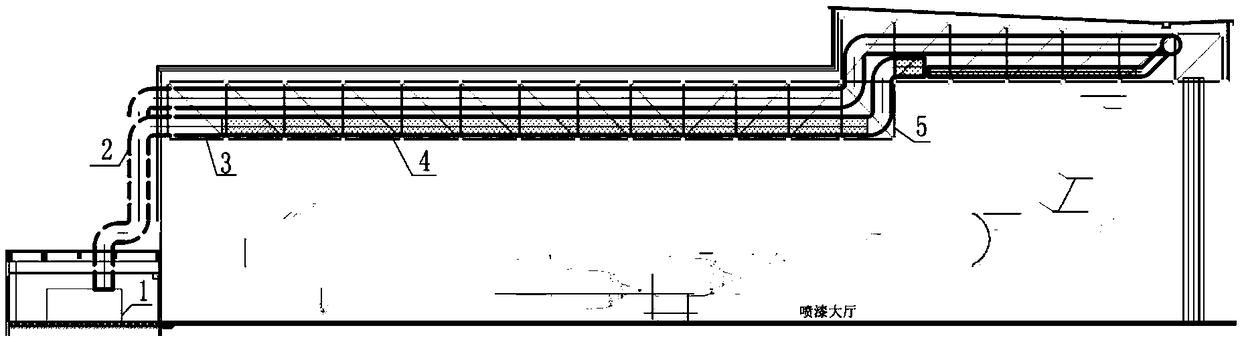

[0025] Present embodiment adopts the painting hangar of air supply system of the present invention to be Boeing 747-8 model spray painting, see appendix figure 1 As shown, this kind of air supply system applicable to the ventilation of the overall paint spraying of the aircraft includes the metal air duct 2 arranged along the outer wall of the hangar hall 4 and the roof grid frame 5 of the hangar hall. In the present embodiment, the roof of the hangar hall is In the form of a net frame, the blower unit 1 is a combined air-conditioning unit, which is arranged in a dedicated blower room. There are 6 sets in total, and the air volume of a single set is 50,000m3 / h~150,000m3 / h. The combined air-conditioning unit has heating and humidifying functions, and can process outdoor fresh air and deliver it to the hangar hall. Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com