Low-frequency sound field regulation type swing arc tungsten-electrode argon arc welding device and method

A technology of argon tungsten arc welding and welding equipment, which is applied in the direction of electrode support equipment, arc welding equipment, welding equipment, etc., can solve problems such as cold wall defects, poor fusion of side walls, welding spatter, etc., to simplify complex structures and improve Effect of cold wall defects and poor fusion of side walls, reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in combination with specific embodiments.

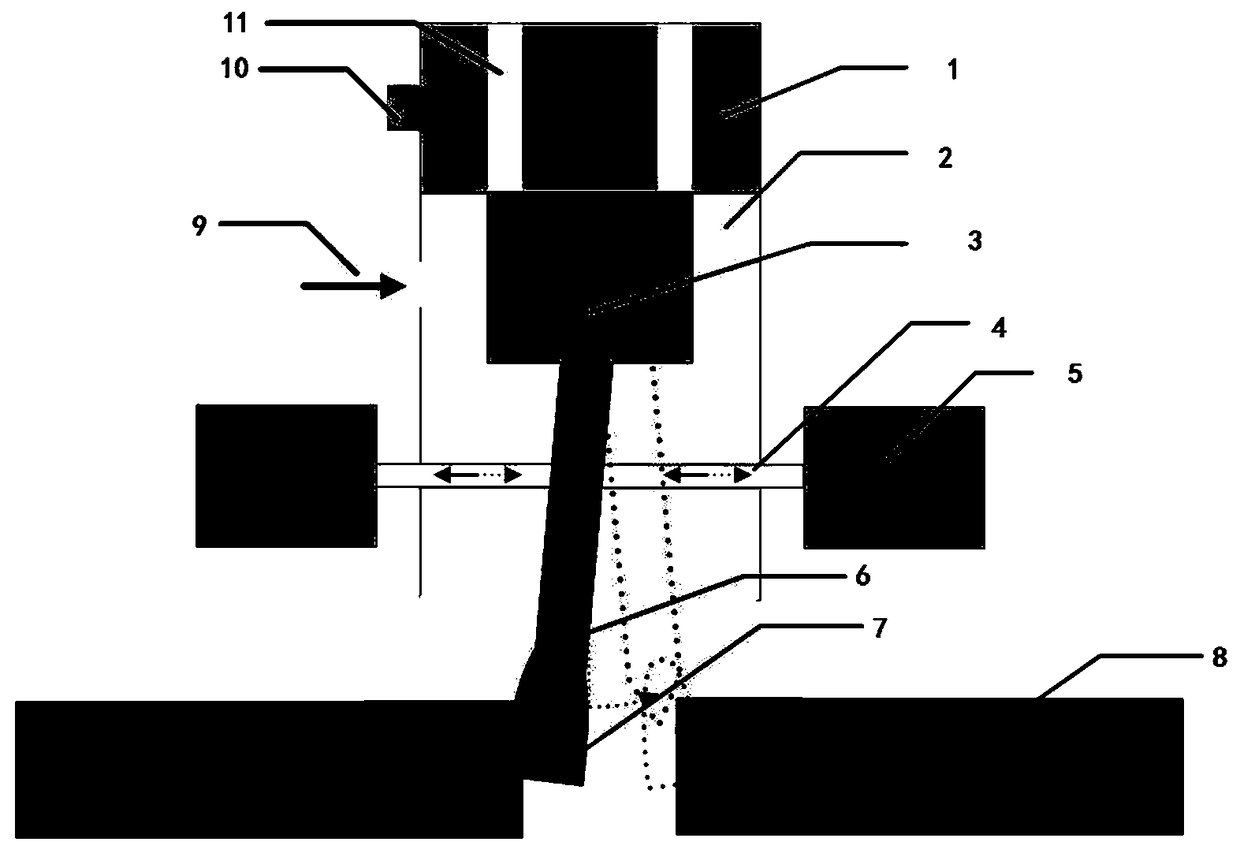

[0016] Such as figure 1 As shown, the 5A06 aluminum alloy with a thickness of 40mm is welded, the welding joint is a butt joint, and the welding device includes argon tungsten arc welding torch 1, connector 2, gas mask 3, guide rod 4, acoustic wave generator 5, and tungsten electrode 6 , Swing arc 7, workpiece to be welded 8, gas channel 9, conductive channel 10, cooling water channel 11. The connecting piece 2 is fixed by the recessed table inside the argon tungsten arc welding torch 1 and the screw thread, the tungsten electrode 6 is connected with the connecting piece 2 through the thread, and the guide rod 4 passes through the hole on the gas mask and the sound wave generator at both ends 5 and the tungsten electrode 6 are connected by threads, and the gas mask 3 is locked on the argon tungsten arc welding torch 1 through the joint action of the threads and the top wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com