Ship engine room temporary ventilation method

A ventilation method and engine room technology, applied in hull ventilation/heating/cooling, ship construction, ship design, etc., can solve problems such as reduced production efficiency, harsh operating environment, and difficult ventilation, and reduce the impact of height and gas weight. The effect of purifying the construction work environment and increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

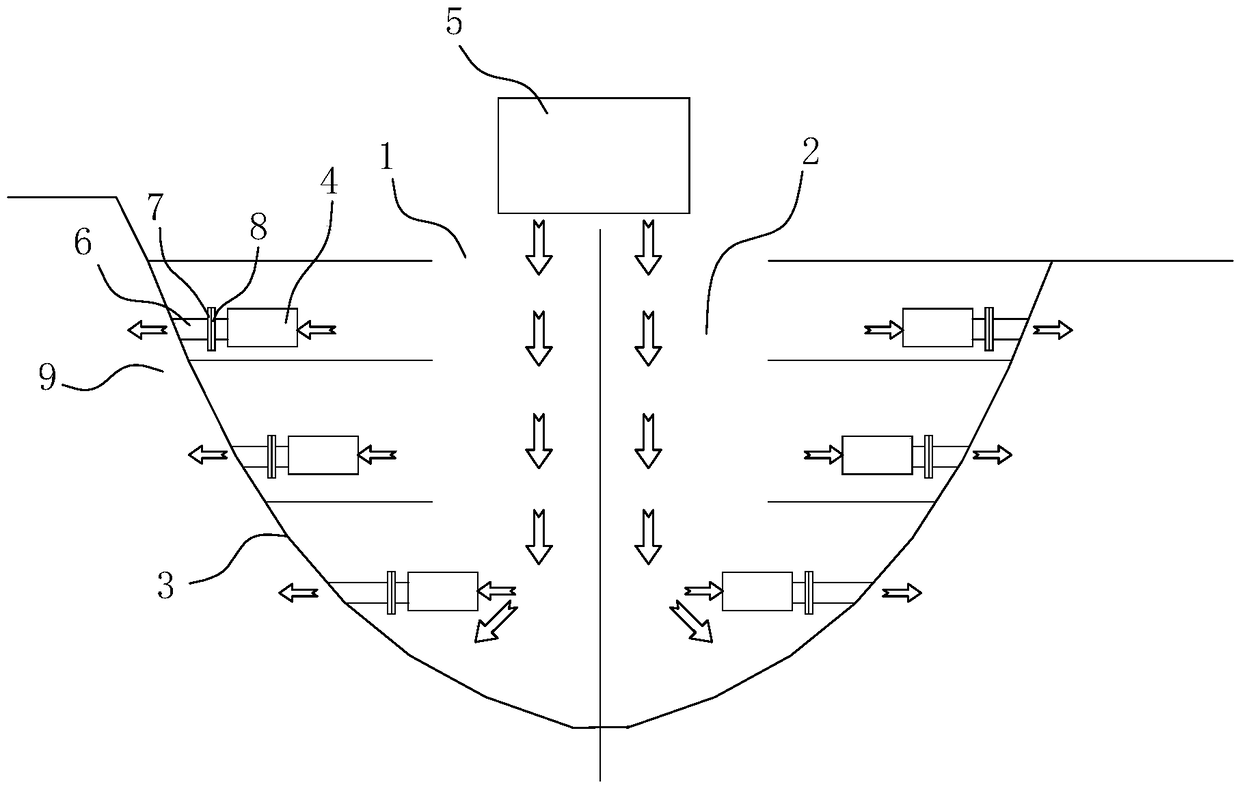

[0025] Such as figure 2 As shown, among them, figure 2 The arrows in the figure represent the flow direction of the gas. In this embodiment, a temporary ventilation method for a ship engine room according to the present invention is provided with a side pipe 6 on the side wall 3 of the engine room, and the side pipe 6 Connect the outside of the engine room with the engine room cavity 2, temporarily install a pipeline exhaust fan 4 near the end of the engine room cavity 2 on the side pipe 6, and the pipeline exhaust fan 4 is used to remove the engine room cavity 2 The gas in the engine room is pumped through the side pipe 6 to the outside 9 of the engine room.

[0026] After the main hull of the ship is carried and formed, a semi-closed engine room is formed. In the present embodiment, the size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com