Full-automatic constant water level sequential batch water-draining system and water-draining method thereof

A water outlet system, constant water level technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the water level electrode is not well maintained and the electrode is prone to send out error signals , effluent quality decline and other problems, to achieve the effect of good effluent quality, not easy to run mud, and stable effluent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

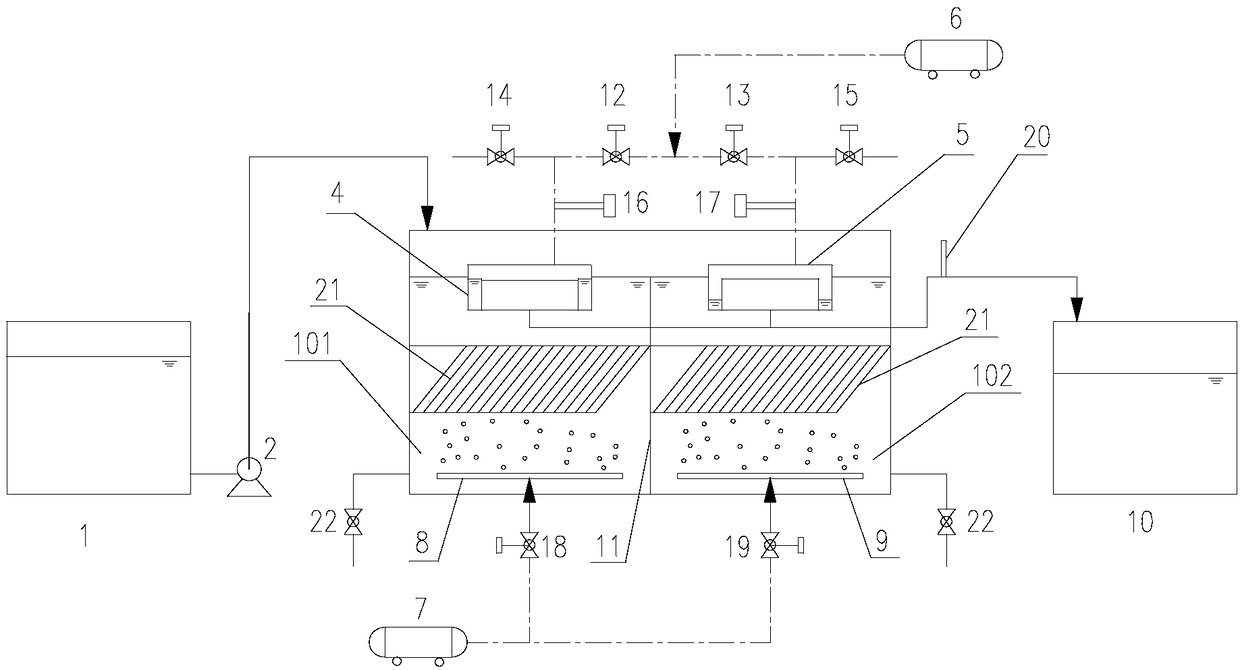

[0030] Depend on figure 1 As shown, the fully automatic constant water level sequence batch operation water outlet system of the present invention includes a water inlet tank 1, an inlet pump 2, a sequence batch reaction tank 3, a first air weir 4, a second air weir 5, a first air compressor 6, The second air compressor 7, the first aerator 8, the second aerator 9, and the water outlet tank 10. A water inlet pump 1 is provided on the pipeline connecting the water inlet tank 1 and the sequencing batch reaction tank 3 . Both the water outlets of the first air weir 4 and the second air weir 5 are connected to the water outlet pool 10 , and the pipelines between the water outlets of the second air weir 5 and the water outlet pool 10 are provided with an air supply port 20 . Both the first aerator 8 and the second aerator 9 are connected with the second air compressor 7 .

[0031] Partition plate 11 is arranged in described sequence batch reaction tank 3, sequence batch reaction ...

Embodiment 2

[0048] Embodiment 2 and Embodiment 1 only have certain differences in the drainage control method, except that, others are all the same, and the differences are as follows:

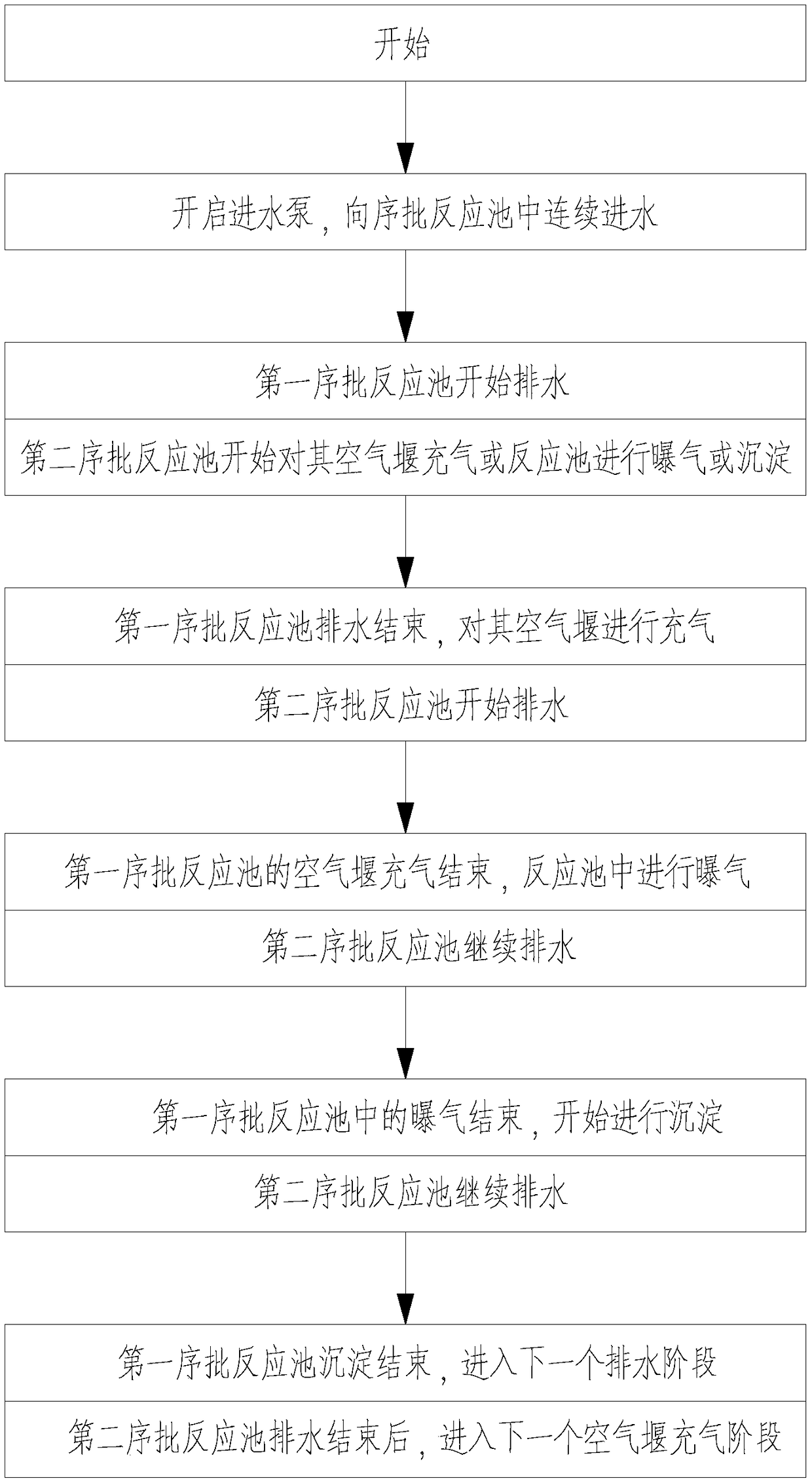

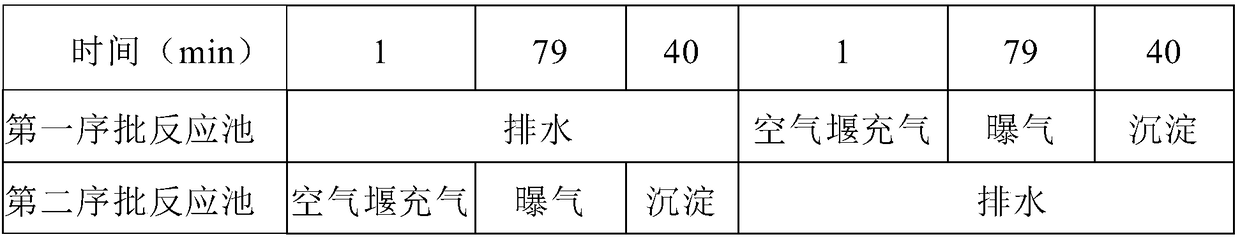

[0049] (1) Sewage is continuously pumped into the sequence batch reaction tank by the water inlet pump 1, and the first air inlet valve 12 is opened to start aerating in the first air weir 4; Exhaust, and the second sequence batch reaction tank 102 starts to drain water;

[0050] (2) After the first air weir 4 is inflated for 0.5min, the air pressure in the first air weir 4 reaches the set maximum value of 5kPa. At this time, the first air inlet valve 12 is closed, and the second air compressor 7 and the second air compressor are opened. Three air inlet valves 18 are used to aerate in the first sequence batch reaction tank 101; at this time, the second sequence batch reaction tank 102 continues to drain water, and when the second air weir 5 is exhausted until the pressure is reduced to the set minimum val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com