Preparation method of rare earth composite stabilizer for PVC

A rare earth compound and stabilizer technology, applied in the field of PVC stabilizers, can solve the problems of unproven light stability, lack of competitiveness, and reduction of manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

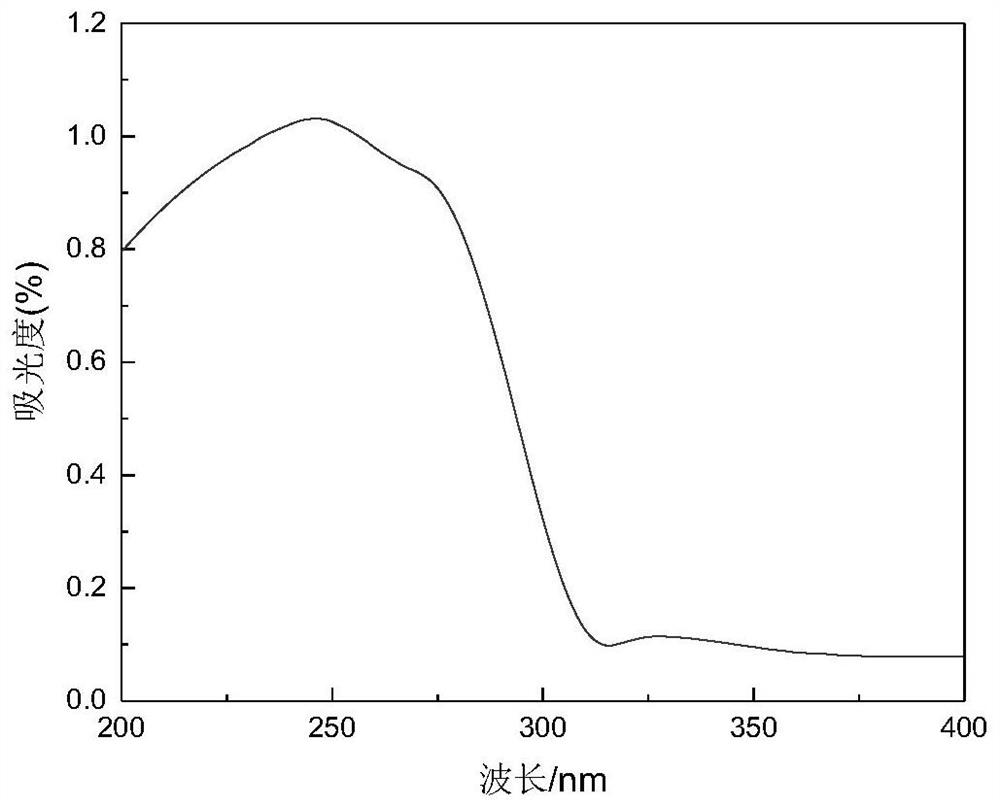

[0027] Preparation of lanthanum p-toluate

[0028] (1) Take 20g of lanthanum chloride and place it in a beaker, then add 100ml of dehydrated ethanol solution to dissolve it, and configure it into a 0.20g / ml dehydrated ethanol solution;

[0029] (2) Put 25 g of p-toluic acid in a beaker, add 500 ml of absolute ethanol to dissolve it, place the beaker in a constant temperature water bath, heat and stir, and prepare an absolute ethanol solution with a mass of 0.05 g / ml. Then slowly add the solution prepared in the above system, the reaction temperature is 60°C, and stir for 45 minutes;

[0030] (3) Use a peristaltic pump to add 250 ml of sodium hydroxide ethanol solution with a molar concentration of 2 mol / L, and add in 60 minutes to make the pH of the solution 6.5, then stir at constant temperature for 1 hour. Let it stand for 12 hours, filter, wash with absolute ethanol, water, and absolute ethanol in sequence, and dry at 62°C to obtain lanthanum p-toluate.

[0031] Preparati...

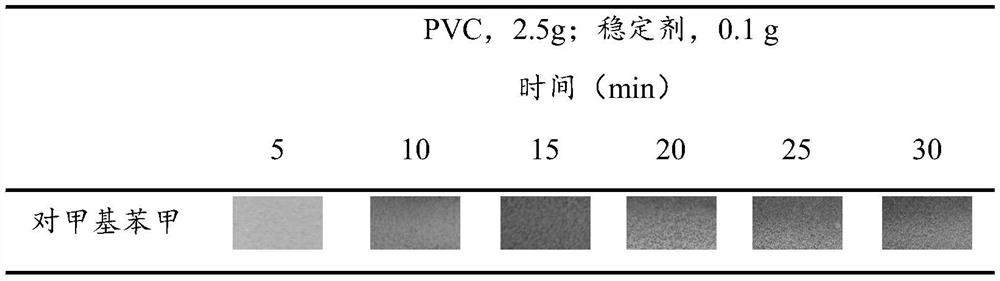

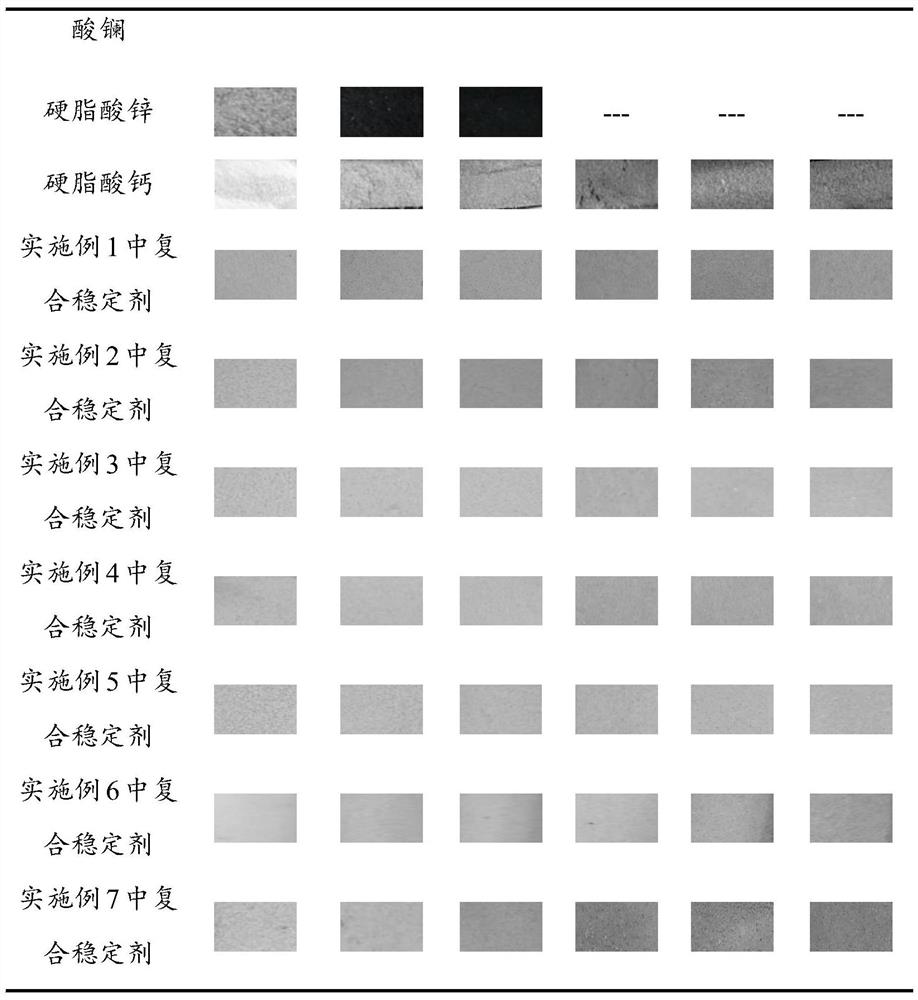

Embodiment 1

[0040]40g of lanthanum p-toluate and 160g of calcium stearate were put into a high-speed mixer and mixed for 4 minutes to obtain a mixed stabilizer.

Embodiment 2

[0042] Put 80g of lanthanum p-toluate and 120g of pentaerythritol into a high-speed mixer and mix for 3 minutes to obtain a mixed stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com