Rare-earth imidazolecarboxylate composite thermal stabilizer for PVC and preparation method of rare-earth imidazolecarboxylate composite thermal stabilizer

A composite stabilizer and rare earth composite technology, which is applied in the field of stabilizers, can solve the problems of poor thermal stability, poor durability, and high price, and achieve the effects of increased compatibility, low price, and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

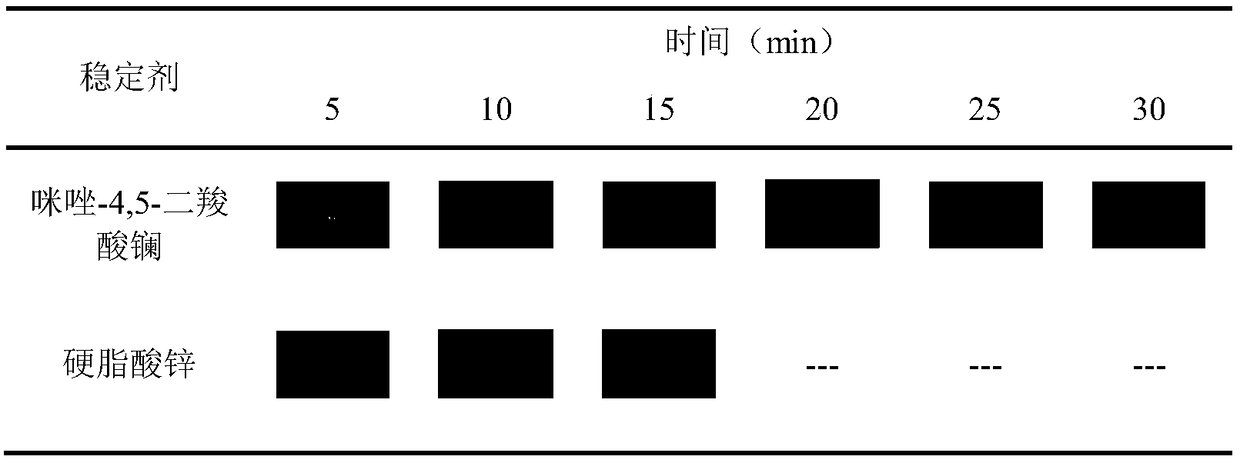

[0024] Preparation of lanthanum imidazole-4,5-dicarboxylate:

[0025] Put 50 g of imidazole-4,5-dicarboxylic acid in a beaker, add 800 mL of deionized water to dissolve, and prepare an imidazole-4,5-dicarboxylic acid solution with a mass concentration of 0.0625 g / ml. Measure 200mL of lanthanum chloride solution with a molar concentration of 1mol / L and put it in a beaker, place the beaker in a water bath, heat and stir to 60°C, add the imidazole-4,5-dicarboxylic acid solution drop by drop to the above system. After the dropwise addition, use a peristaltic pump to add 1,000 ml of aqueous sodium hydroxide solution with a molar concentration of 1 mol / L, and add in 60 minutes to make the pH of the solution = 5, then stir at constant temperature for 5 hours. Cool to room temperature, filter, wash, and dry at 70°C to obtain lanthanum imidazole-4,5-dicarboxylate.

[0026] Preparation of cerium imidazole-4,5-dicarboxylate:

[0027] Put 75g of imidazole-4,5-dicarboxylic acid in a bea...

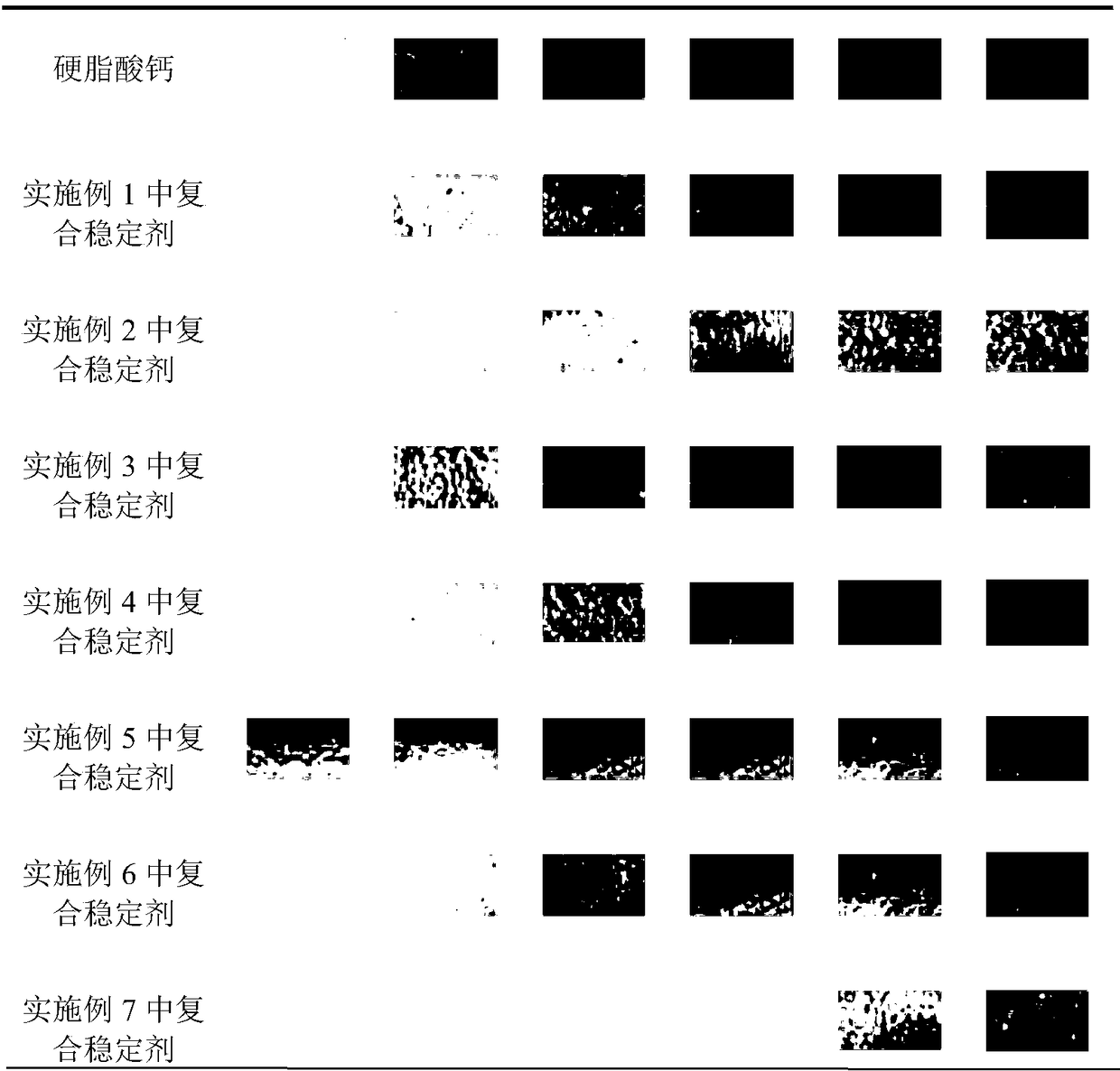

Embodiment 1

[0031] Put 120g of imidazole-4,5-lanthanum dicarboxylate and 80g of calcium stearate into a high-speed mixer and mix for 2 minutes to obtain a composite stabilizer.

Embodiment 2

[0033] Put 80g of lanthanum imidazole-4,5-dicarboxylate and 120g of glycerol into a high-speed mixer and mix for 3 minutes to obtain a composite stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com