Flame-retardant anti-static fabric and production process thereof

An anti-static fabric and production process technology, applied in the field of textile weaving, can solve the problems of poor strength, hand feeling and washing resistance, and achieve the effect of excellent comprehensive wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

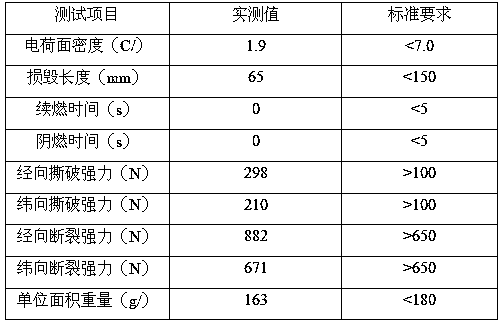

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0013] A flame-retardant and anti-static fabric, which is made of high-performance fiber, flame-retardant fiber and conductive fiber. The mixing ratio of the three is 15:83:2. The high-performance fiber uses aramid fiber, and the flame-retardant fiber Modified acrylic fibers obtained by polymerization of vinyl chloride as a comonomer and acrylonitrile. The conductive fibers are composite organic conductive fibers with polyamide and carbon black as the matrix and conductive components respectively. Due to the compatibility and complementarity of the three main functions, thus The fabric not only has the long-lasting protective function of flame retardant and anti-static, but also has excellent comprehensive wearing properties such as high wear resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com