Producing method of three-warp three-weft light and thin fabric

A light and thin fabric technology, applied in the field of umbrella surface fabrics, can solve the problems such as easy drop of the drop piece, fine yarn count, easy end breakage of the warp yarn, etc., and achieve the effect of low weaving process cost, good application prospect, and loose yarn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

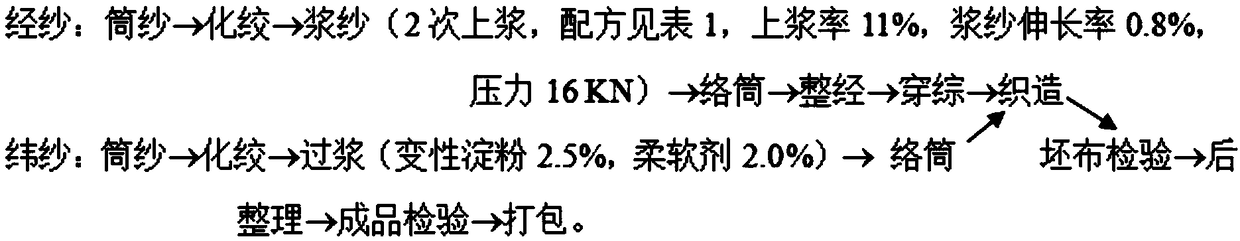

[0025] The spinning process such as figure 1 shown.

[0026] Table 1 warp yarn sizing formula (unit: %)

[0027]

PVA

softener

the first time

2.5

0.55

0.30

the second time

1.5

0.50

1.50

[0028] Warp and weft: 100 s ×100 s PET white yarn / black yarn, warp and weft yarn density: 615×562 threads / cm; fabric tightness: warp direction 44.5%, weft direction 33.4%, total tightness 63.5%; fabric structure: plain weave (Minger); fabric width 150cm.

[0029] The warping control tension is 8% of the single yarn strength, the tension difference between single yarns is not more than 2cN, and the unevenness is less than 1.5%. A section warping machine is adopted with a machine speed of 450r / min. The intermittent warping reciprocating creel is adopted, and the tension disc adopts a double-disc structure. The pressure is controlled by the angle of the disc and the weight of the tension disc. It is driven by...

Embodiment 2

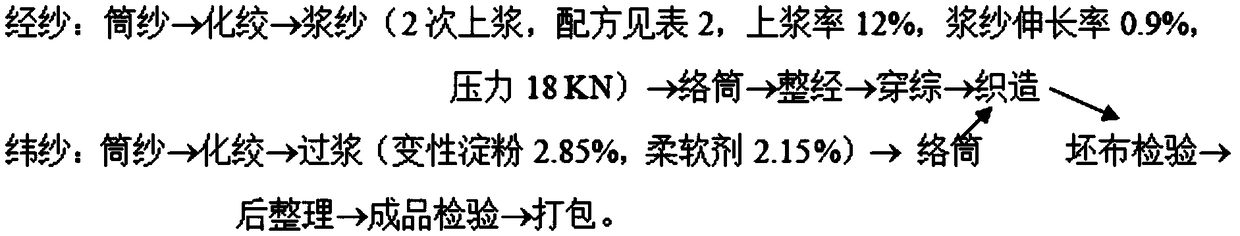

[0033] The spinning process such as figure 2 shown.

[0034] Table 2 warp yarn sizing formula (unit: %)

[0035]

PVA

softener

the first time

2.7

0.58

0.35

the second time

1.8

0.60

1.7

[0036] Warp and weft: 80 s ×80 s PET white yarn / black yarn, warp and weft yarn density: 413×512 threads / cm; fabric tightness: warp direction 41.3%, weft direction 31.5%, total tightness 62.1%; fabric structure: plain weave (Minger); fabric width 155cm.

[0037] The warping control tension is 9% of the single yarn strength, the tension difference between single yarns is not more than 2cN, and the unevenness is less than 1.5%. A section warping machine is adopted with a machine speed of 450r / min. The intermittent warping reciprocating creel is adopted, and the tension disc adopts a double-disc structure. The pressure is controlled by the angle of the disc and the weight of the tension disc. It is driven by a ...

Embodiment 3

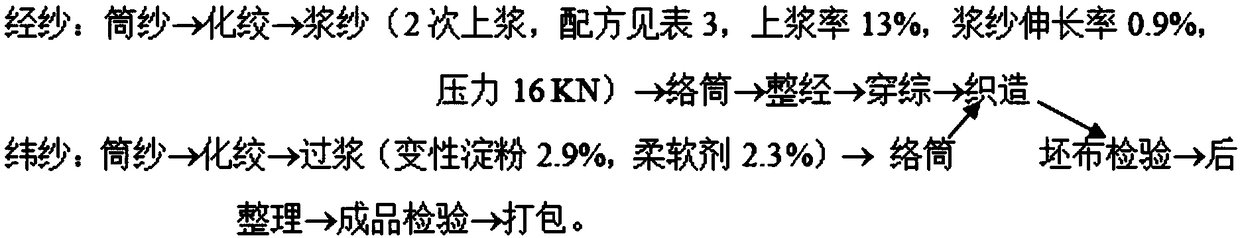

[0041] The spinning process such as image 3 shown.

[0042] Table 3 warp yarn sizing formula (unit: %)

[0043]

PVA

softener

the first time

2.65

0.60

0.40

the second time

2.0

0.75

1.80

[0044] Warp and weft: 120 s ×120 s PET white yarn / blue yarn, warp and weft yarn density: 764×684 threads / cm; fabric tightness: warp direction 47.5%, weft direction 36.4%, total tightness 62.1%; fabric structure: plain weave (Minger); fabric door The width is 150cm.

[0045]The warping control tension is 8.5% of the single yarn strength, the tension difference between single yarns is not more than 2cN, and the unevenness is less than 1.5%. A section warping machine is adopted with a machine speed of 450r / min. The intermittent warping reciprocating creel is adopted, and the tension disc adopts a double-disc structure. The pressure is controlled by the angle of the disc and the weight of the tension disc. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com