Moisture-absorbing and sweat-releasing antibacterial fabric and preparation method thereof

A moisture-wicking and anti-bacterial fabric technology, applied in the field of knitted fabrics, can solve the problems of bacterial reproduction, hindering activities, poor moisture-wicking performance, etc., and achieve the effect of improving wearing comfort, improving wearing comfort, and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] This case proposes a method for preparing a moisture-absorbing and sweat-wicking antibacterial fabric, which includes the following steps: soaking the gray cloth with an antibacterial treatment solution and a moisture-wicking finishing solution to obtain the moisture-wicking and antibacterial fabric; the gray fabric is composed of the following parts by weight Made from a blend of raw materials:

[0028] 12-14 parts by weight of Coolmax fiber;

[0029] 40-50 parts by weight of regenerated cellulose fibers;

[0030] 6-8 parts by weight of polyacrylonitrile fiber.

[0031] The Coolmax fiber four-pipe fiber forms the largest space between the fibers and ensures the best air permeability. It quickly conducts the moisture emitted from the skin surface to the outer fiber, keeps the skin refreshed, and makes the activities more comfortable. It has good air conductivity. Moisture, the knitted fabric interwoven with other fibers has a good moisture-wicking effect; by adding po...

Embodiment 1

[0049] A method for preparing a moisture-absorbing and sweat-wicking antibacterial fabric, comprising the steps of:

[0050] (1) The gray cloth is blended with Coolmax fiber and regenerated cellulose fiber into a blended yarn by a conventional process, and then the blended yarn and polyacrylonitrile fiber are knitted and woven by a weft knitting circular machine to obtain a gray cloth. The gray cloth is made by blending the following raw materials in parts by weight:

[0051]

[0052] (2) gray cloth padding antibacterial treatment liquid obtains antibacterial fabric; the mass ratio of gray cloth and antibacterial treatment liquid is 100:4, and antibacterial treatment liquid is made up of the component of following weight parts:

[0053]

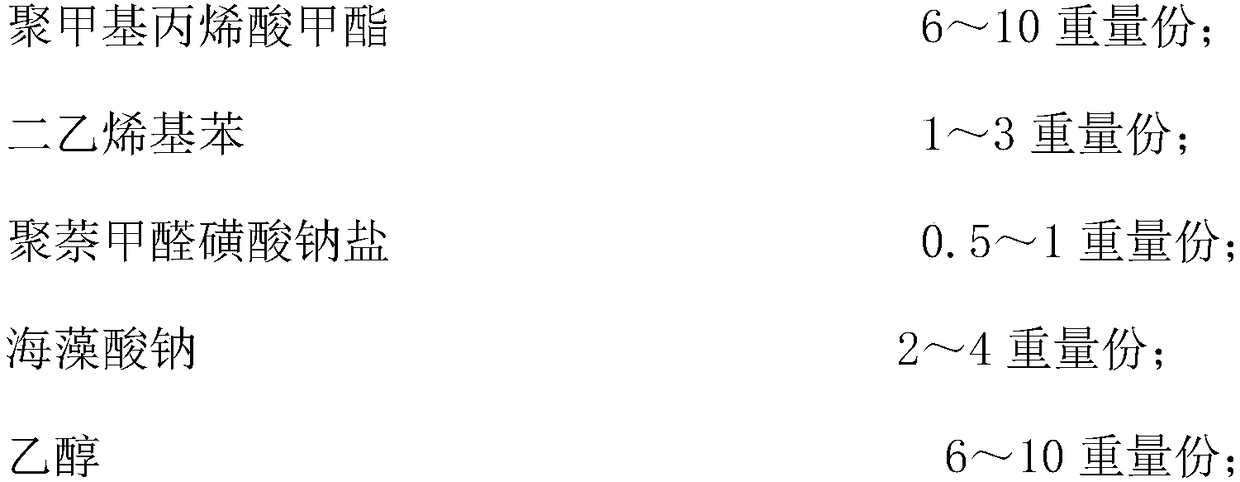

[0054] (3) The gray cloth is soaked with the moisture-absorbing and sweat-wicking finishing solution to obtain the moisture-wicking and antibacterial fabric; the mass ratio of the gray cloth to the moisture-wicking and sweat-wicking fin...

Embodiment 2

[0059] A method for preparing a moisture-absorbing and sweat-wicking antibacterial fabric, comprising the steps of:

[0060] (1) The gray cloth is blended with Coolmax fiber and regenerated cellulose fiber into a blended yarn by a conventional process, and then the blended yarn and polyacrylonitrile fiber are knitted and woven by a weft knitting circular machine to obtain a gray cloth. The gray cloth is made by blending the following raw materials in parts by weight:

[0061]

[0062] (2) gray cloth padding antibacterial treatment liquid obtains antibacterial fabric; the mass ratio of gray cloth and antibacterial treatment liquid is 100:5, and antibacterial treatment liquid is made up of the component of following parts by weight:

[0063]

[0064] (3) The gray cloth is soaked with the moisture-absorbing and sweat-wicking finishing solution to obtain the moisture-absorbing and sweat-wicking antibacterial fabric; the mass ratio of the gray cloth to the moisture-wicking an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com