Landfill impermeable membrane stress relief structure using rubber airbags

A technology of rubber airbags and anti-seepage membranes, which is applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of landfill time limit, loss of fixing function, pull-up of anchorage area of anti-seepage membrane, etc., and achieve reduction Reduce the risk of environmental pollution, shorten the construction period, and prevent the effect of puncture tear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

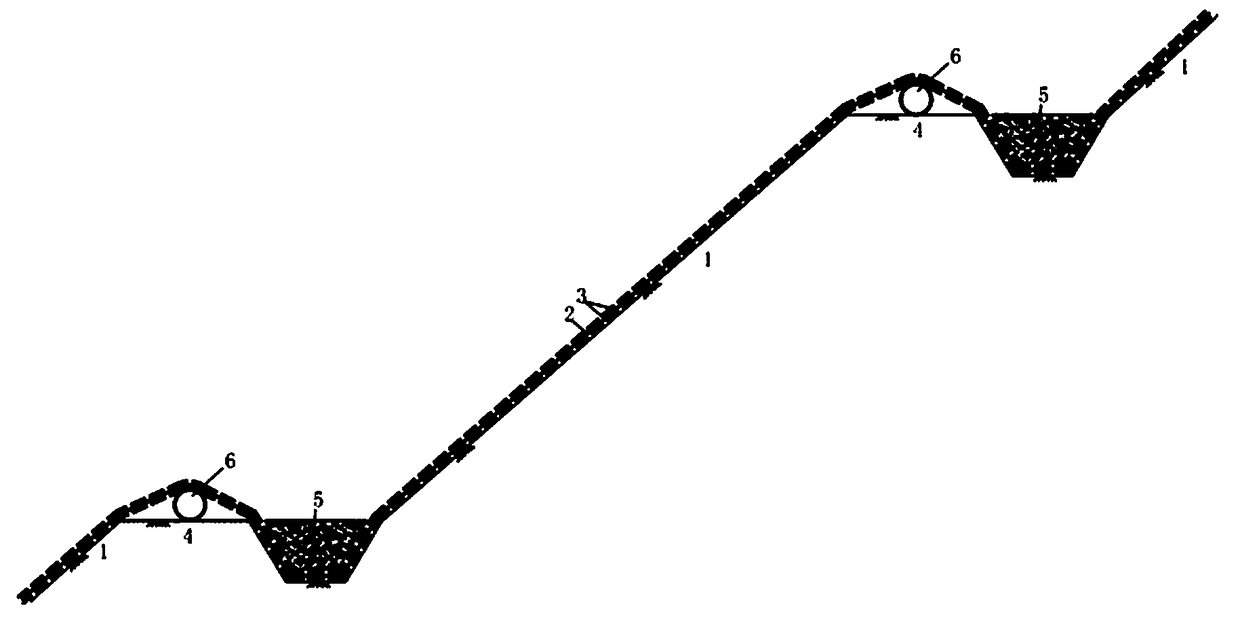

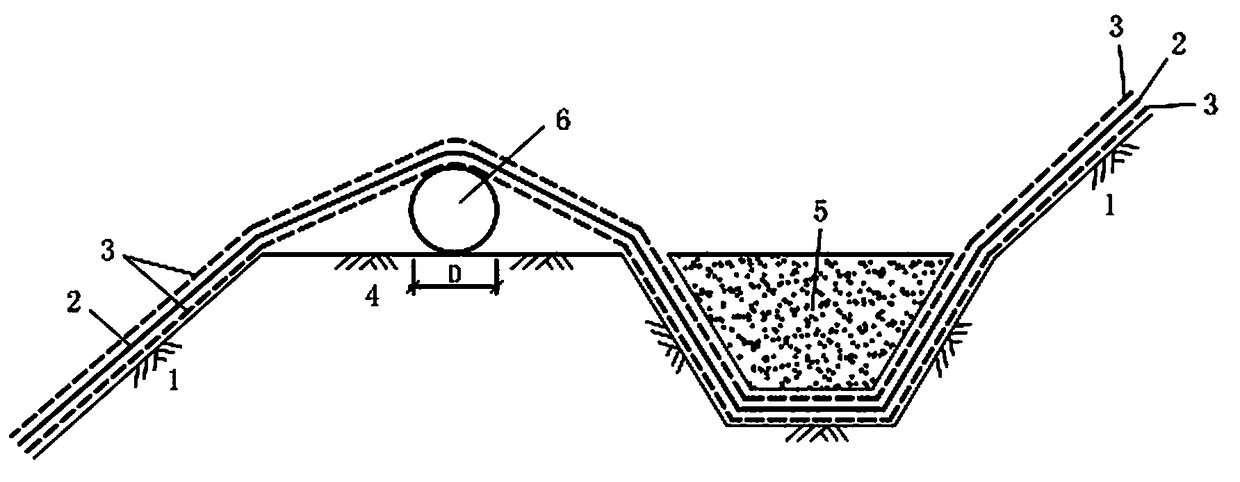

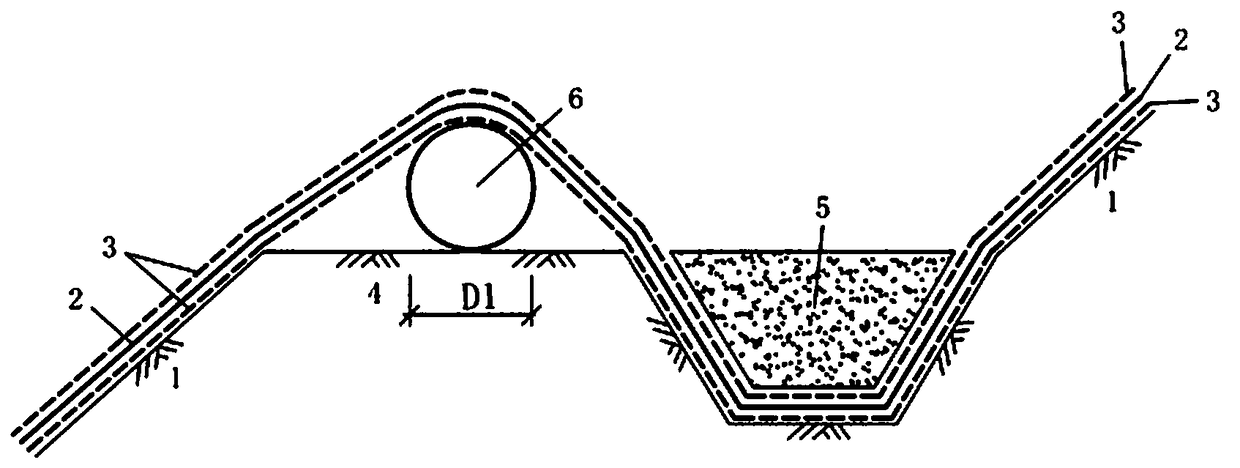

[0023] Embodiments of the present invention will be specifically described based on the drawings. Such as Figure 1~5 As shown, the landfill slope is equipped with a liner system, in which the anti-seepage membrane ensures that the leachate does not leak into the surrounding environment, and the geotextile layers arranged above and below the anti-seepage membrane play the role of protecting the anti-seepage membrane . The liner layer sets the anchorage area at the top of the slope and the upper part of the segmented slope. The anchoring area is a groove anchoring system, and the edges of the impermeable membrane and the geotextile are folded in the groove and fixed with cement concrete.

[0024] In order to alleviate the temperature stress of the anti-seepage membrane, a cylindrical rubber airbag is installed under the anti-seepage membrane at the outer platform of the anchorage groove, and the thickness of the airbag material is 2-5mm. According to the length of the slope ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com