Tower-type derrick lifting device and lifting method

A lifting device and derrick technology, which is applied to supporting devices, drilling equipment, earth-moving drilling, etc., can solve the problems of difficult installation and high risk of tower derricks, and achieve the effects of easy operation, improved safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

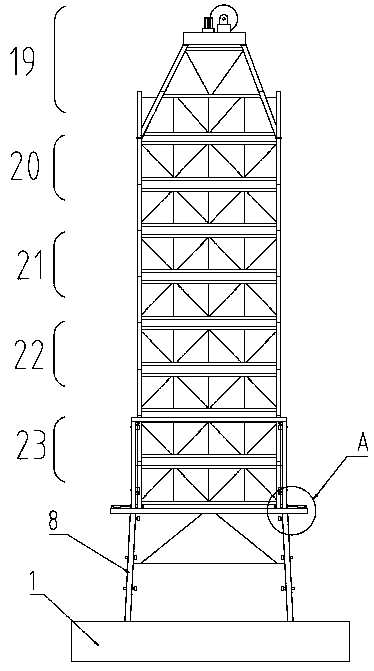

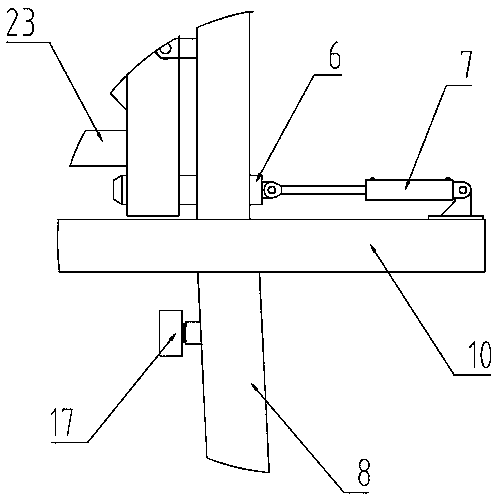

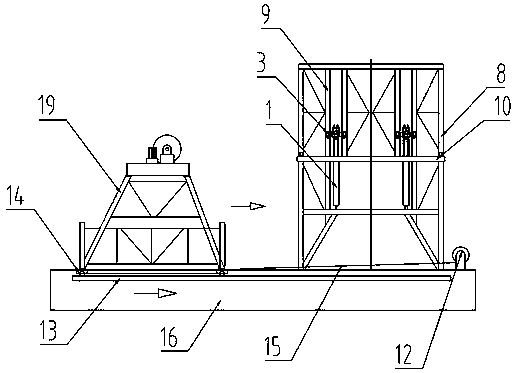

[0047] Example: such as Figure 1 to Figure 10 As shown, a tower derrick lifting device includes a lifting cylinder 1, a lifting pulley 2, a guide block 3, a lifting rope 4, a lifting frame 5, a pin shaft 6, a pinning cylinder 7 and a guide rail groove 9. The lifting cylinder 1 is connected to the derrick lifting section 8, and the piston rod of the lifting cylinder 1 extends upwards to the top of the cylinder block of the lifting cylinder 1, and the lifting pulley 2 is arranged on the piston rod of the lifting cylinder 1. At the upper end, the guide rail groove 9 is arranged on the derrick lifting section 8, the guide block 3 is slidingly connected with the guide rail groove 9, the guide block 3 is connected with the piston rod of the lifting cylinder 1, and the lifting rope 4 is wound On the hoisting pulley 2, one end of the hoisting rope 4 is connected to the derrick hoisting section 8, the other end of the hoisting rope 4 is connected to the hoisting frame 5, and the pinni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com