Shaft tower body construction and wellbore digging and freezing parallel construction system and method

A parallel construction, wellbore technology, applied in wellbore lining, well sinking, shaft equipment, etc., can solve the problems of increased freezing cost and long overall construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

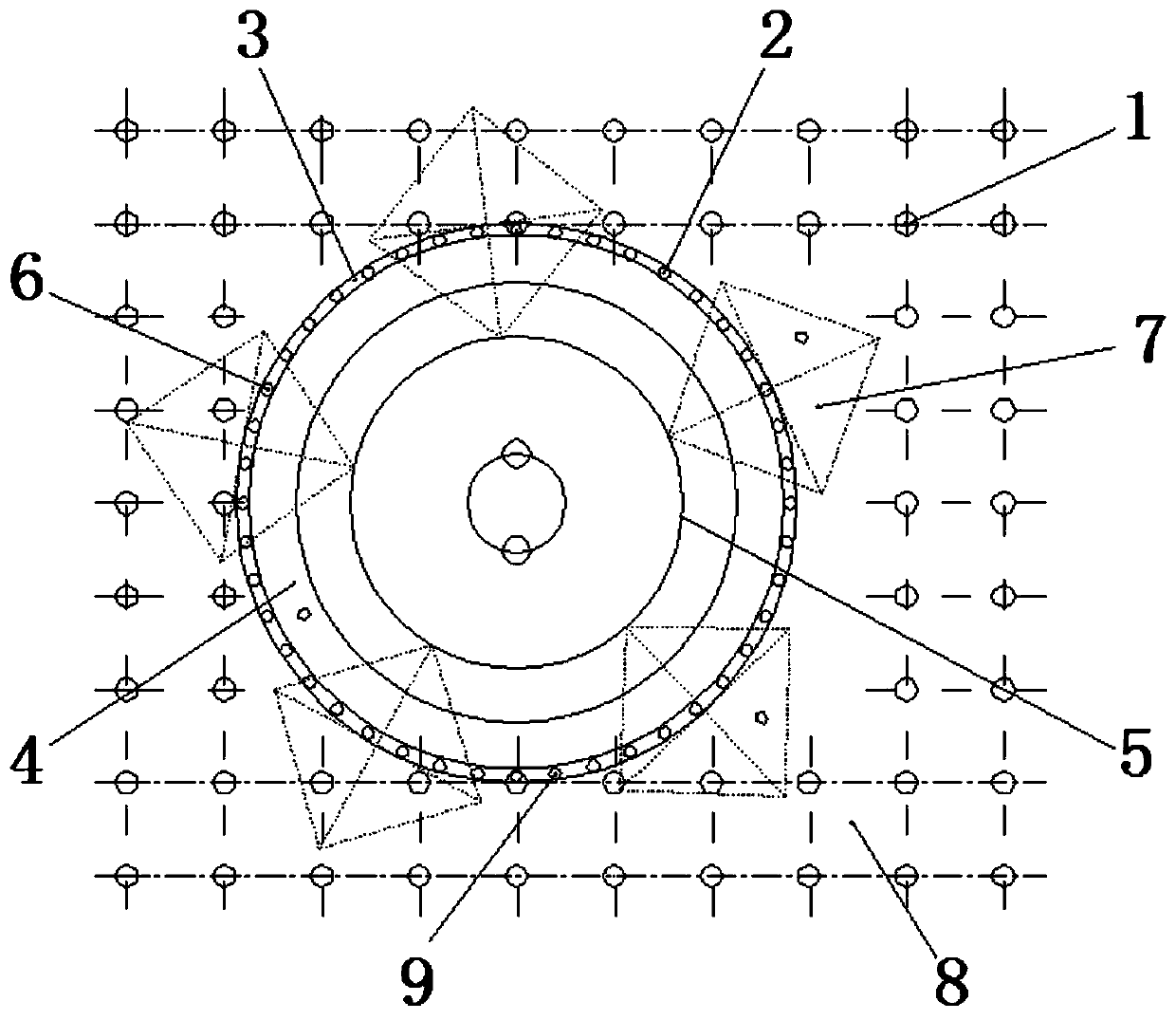

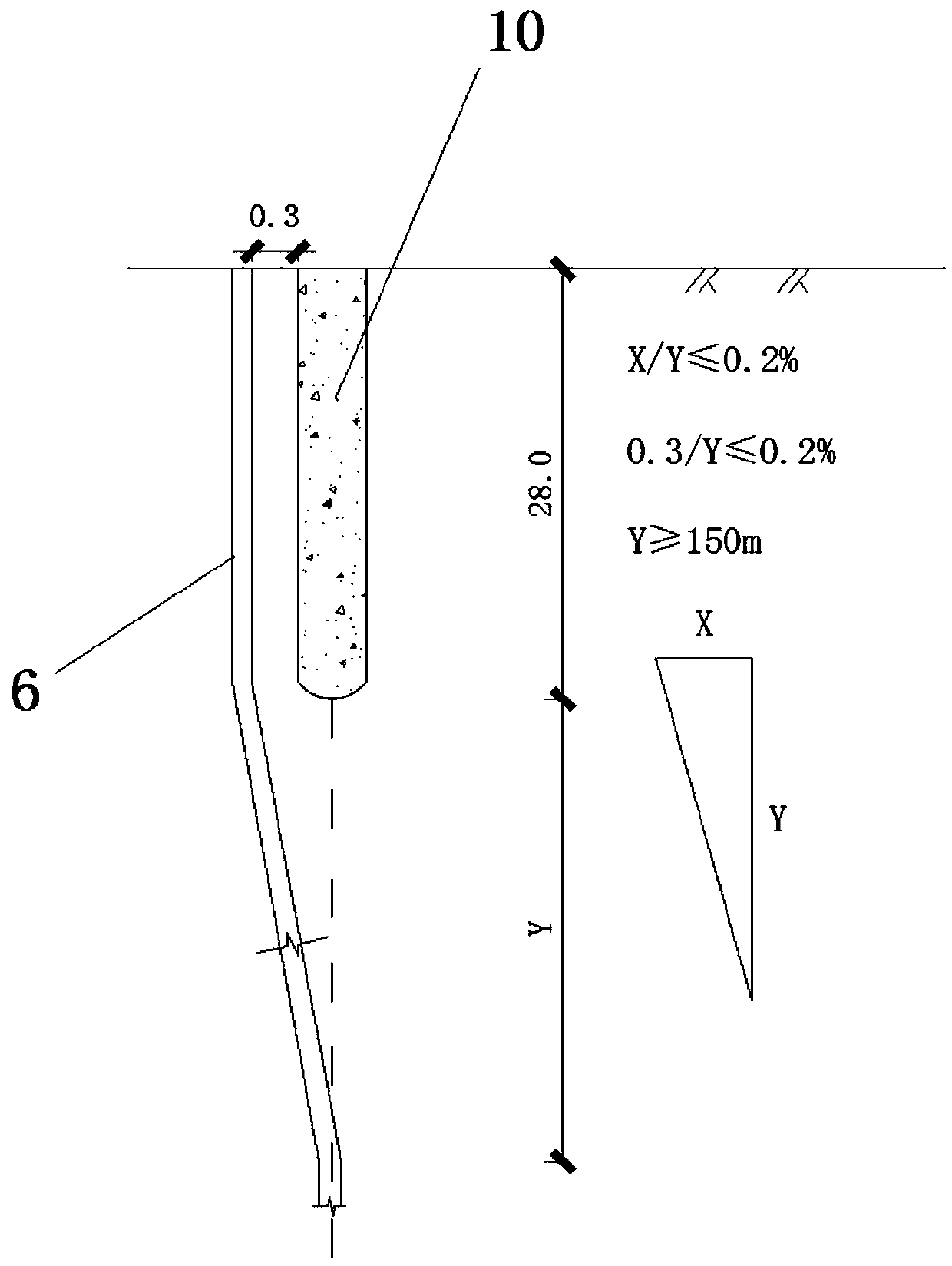

[0065] This example is aimed at the construction of the auxiliary shaft of Bojiang Haizi Coal Mine in the south of Tarangaole Mining Area, Ordos City, Inner Mongolia Autonomous Region. The depth of the vertical shaft is 611m. Shaft 5 is constructed by the freezing method, and the bedrock section is constructed by the ordinary sinking method. The auxiliary shaft is designed to use a reinforced concrete shear wall structure well tower with a height of 66m. The foundation is designed as a large-volume reinforced concrete structure with a buried depth of -6m. The following are bored piles and mud retaining walls. The pile foundation diameter is There are 60 well tower pile foundations 10 with a length of 22m.

[0066] According to the total construction period plan of the mine construction, the key line: freezing-shaft 5 excavation-the construction period of roadway excavation has been determined, and the compression space is already very small. In order not to affect the tota...

Embodiment 2

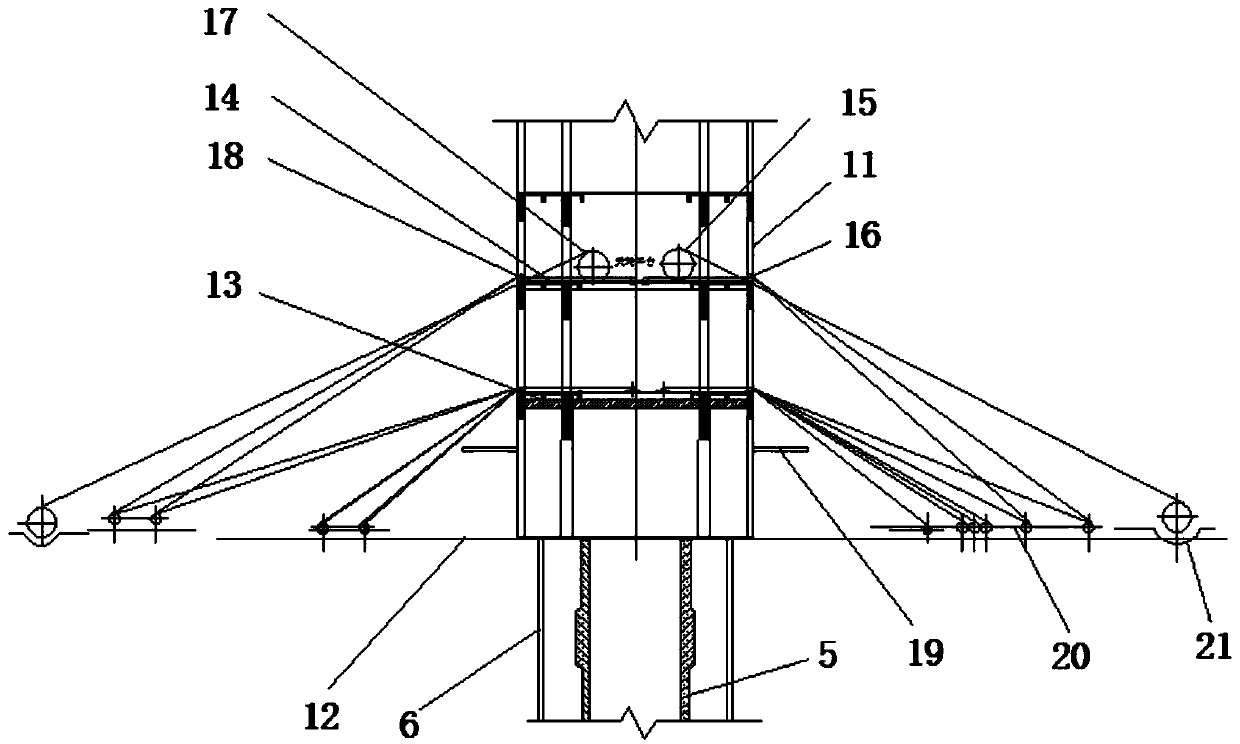

[0078] In this embodiment, the auxiliary shaft of Bojiang Haizi Mine is constructed by permanent tower sinking, the height of the tower is 82 meters, and the maximum capacity is 52709.8m3m 3 , the maximum beam span is 26m, and the maximum support height is 17m. It is divided into four floors of +15.5m, +24m, +32.5m and +44.9m. The sinking construction platform uses two floors of +15.5m and +24m, and uses 4 large steel-concrete columns in the center of the well tower in the center of the well tower at +26.2m to make use of the self-made hoisting winch 21 sky wheel platform.

[0079] Both the main shaft and auxiliary shaft towers of Bojiang Haizi Mine adopt reinforced concrete box structure, adopt sliding form construction, and pour concrete continuously. The construction speed is fast and the formwork reuse rate is high, which can greatly reduce the project cost. In order to fully and accurately grasp the development and change of the internal temperature field of the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com