Multi-way reversing valve and heat pump unit

A heat pump unit and reversing valve technology, applied in the field of air conditioning, can solve the problems of many control valves and complicated control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

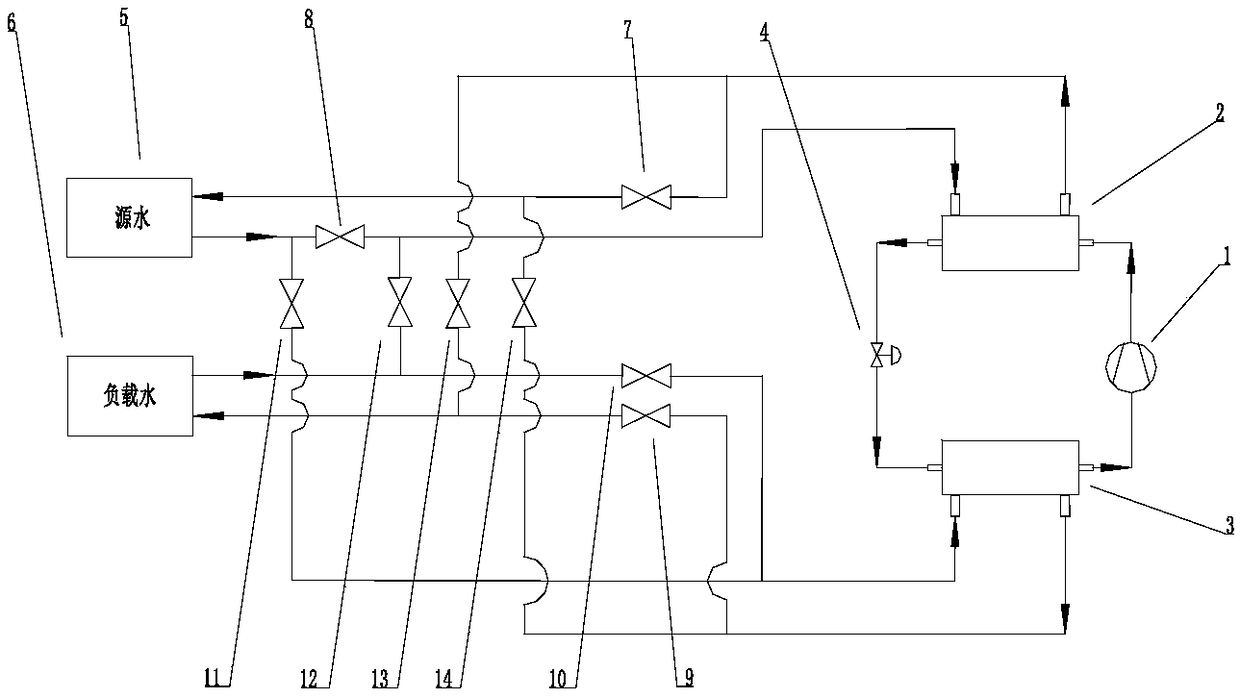

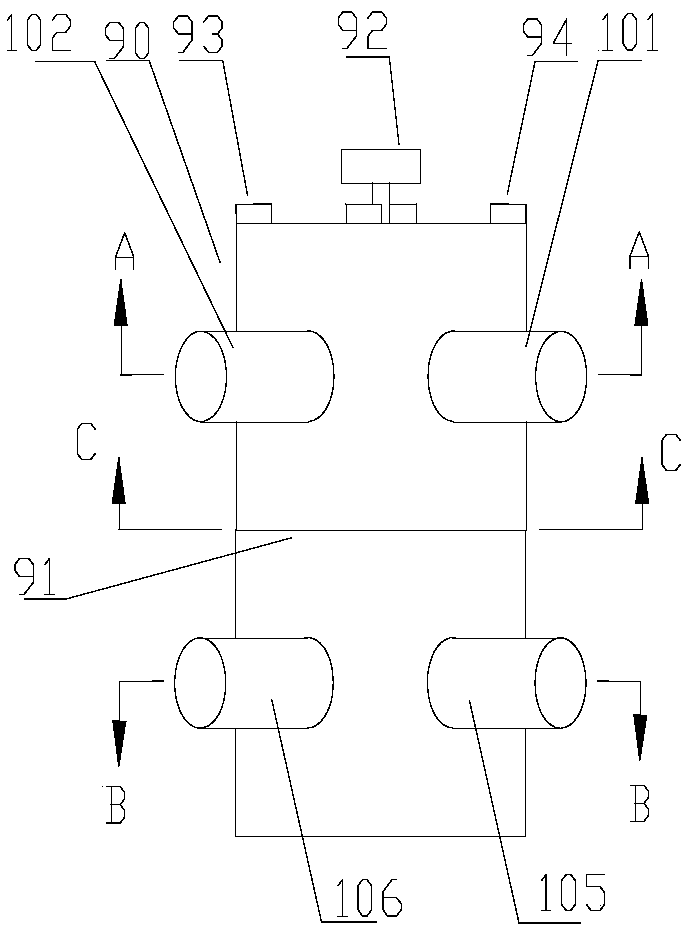

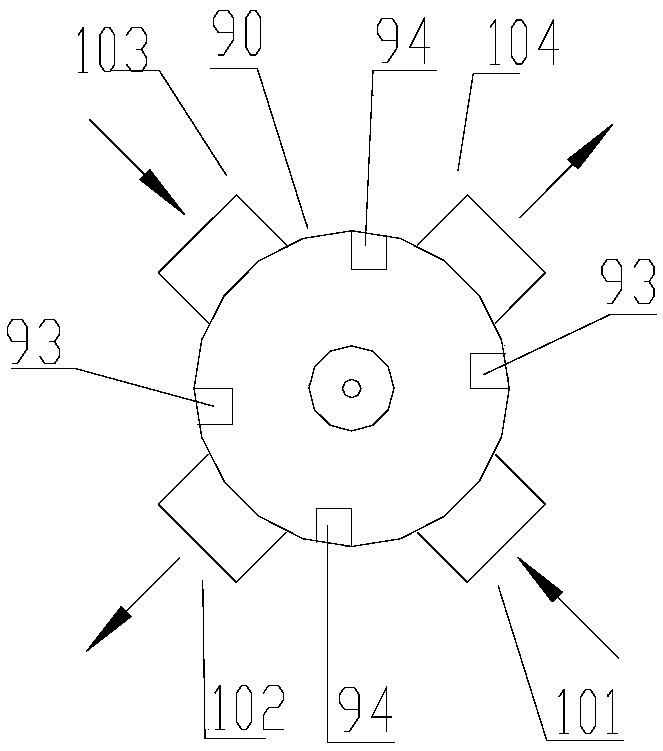

[0120] Example 1 as Figure 4-5 As shown, the heat pump unit is a water source or ground source heat pump unit, and the first cooling source 5 is source water, the second cooling source 7 is load water, and the multi-way reversing valve 9 is The first upper inlet 101 is the first upper water inlet, the first upper outlet 102 is the first upper water outlet, the second upper inlet 103 is the second upper water inlet, and the second upper outlet 104 is the first upper water outlet. Two upper water outlets; the first lower inlet 105 on the multi-way reversing valve 9 is the first lower water inlet, the first lower outlet 106 is the first lower water outlet, and the second lower inlet 107 is the second lower water inlet, and the second lower outlet 108 is the second lower water outlet.

[0121] This is the preferred first structural form of the heat pump unit of the present invention, that is, a water source or ground source heat pump unit, the first cooling source 5 is source wa...

Embodiment 2

[0133] Example 2 as Figure 6-7 As shown, preferably,

[0134] The heat pump unit is an air source heat pump unit, and the first cooling source 5 is indoor return air, the second cooling source 7 is outdoor fresh air, and the first cooling source on the multi-way reversing valve 9 is An upper inlet 101 is the first upper air inlet, the first upper outlet 102 is the first upper air outlet, the second upper inlet 103 is the second upper air inlet, and the second upper outlet 104 is the second upper air outlet ; The first lower inlet 105 on the multi-way reversing valve 9 is the first lower air inlet, the first lower outlet 106 is the first lower air outlet, and the second lower inlet 107 is the second lower air inlet. The air inlet, the second lower outlet 108 is the second lower air outlet.

[0135] This is the preferred first structural form of the heat pump unit of the present invention, which is an air source heat pump unit. The first cooling source 5 is indoor return air,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com