Pome sampler

A sampler and pear technology, applied in sampling, sampling devices, instruments, etc., can solve the problems of time-wasting, low work efficiency, and laborious removal of pear pits, and can prevent excessive pressing from damaging the cutter, operation Convenient, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

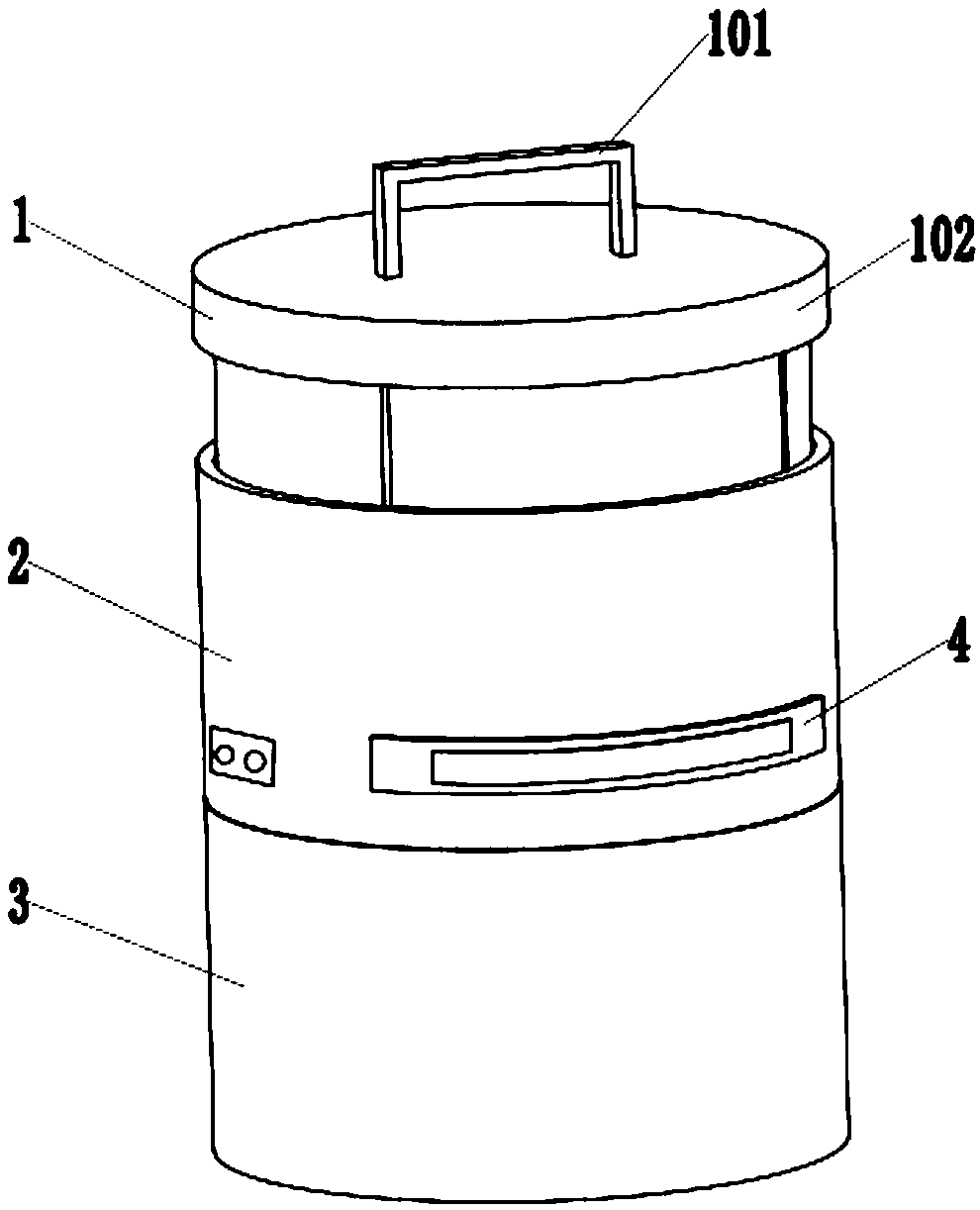

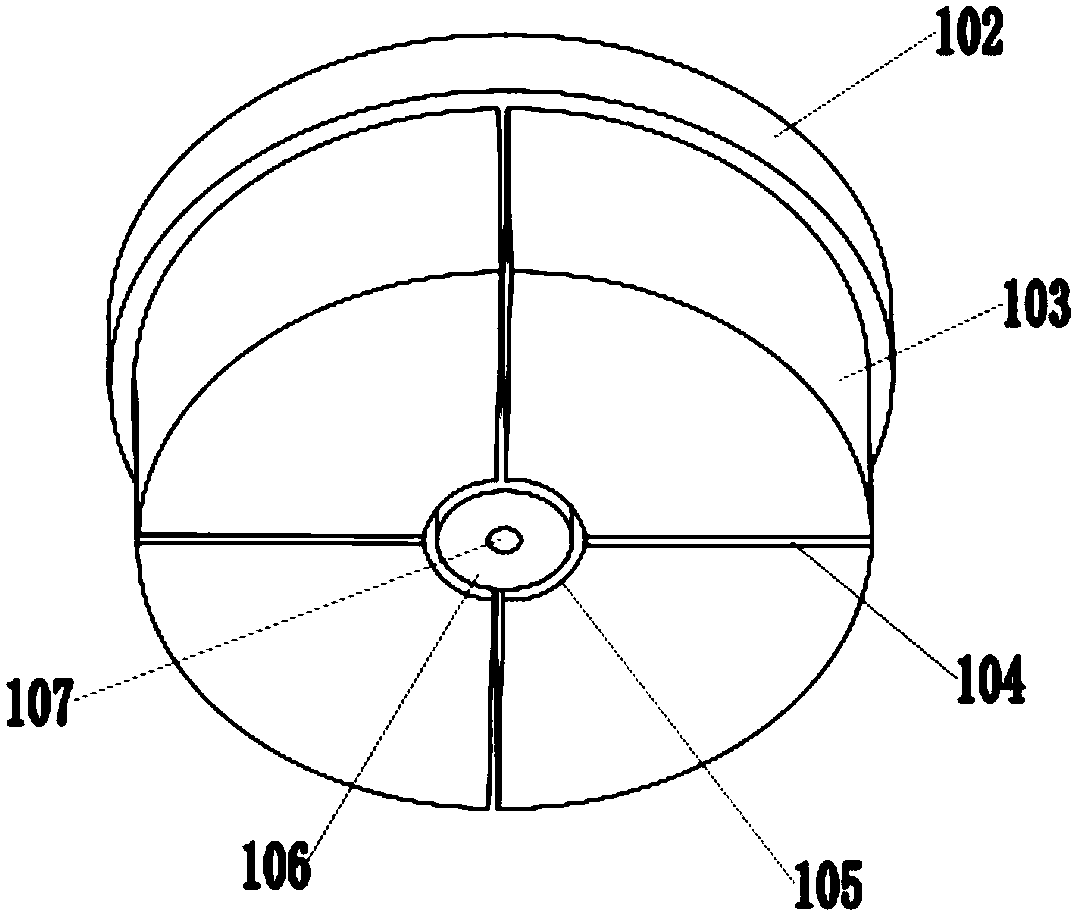

[0031] Such as figure 1 , Figure 5 As shown, a kind of pear fruit sampler comprises cutting bucket 2, and the lower end of described cutting bucket 2 is provided with beating knife 204, and the outside of beating knife 204 is covered with pulp bucket 3, and described fruit pulp bucket 3 and cutting bucket 2 Threaded connection is similar to the structure of a soymilk machine, and one side of the cutting barrel 2 is provided with a power interface. This technology is very commonly used at present, and it is easy for those skilled in the art to understand, so it will not be described in detail. The side inner wall of the fruit pulp barrel 3 is The inclined arc surface can ensure that the pulp gathers at the position of the beating knife 204, and ensures the uniformity of crushing.

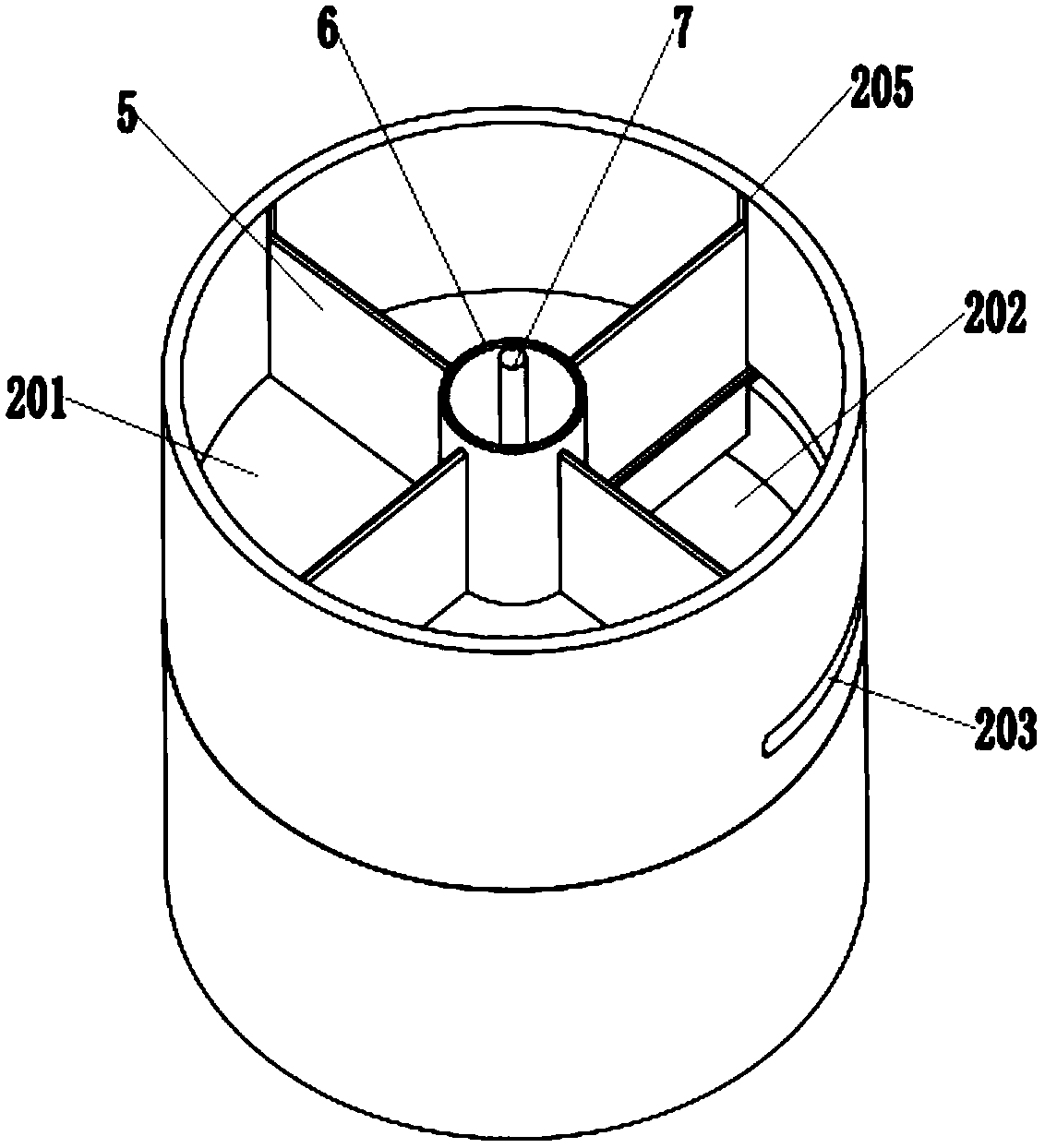

[0032] Such as figure 2 As shown, the middle position in the cutting bucket 2 is vertically provided with a nuclear cutting knife 6, which is connected with the bottom plate 201 of the cutting bu...

Embodiment 2

[0038] The difference between the second embodiment and the first embodiment is that a fixed pin is added.

[0039] Such as figure 2 , Figure 5As shown, the inside of the nuclear cutting knife 6 is provided with a fixed needle 7, the lower end of the fixed needle 7 is provided with a support seat 701, the support seat 701 cooperates with the inner wall of the nuclear cutting knife 6, and the support seat 701 is located on the core During cutting knife 6 bottoms, the upper end of fixed needle 7 is higher than the upper end of nuclear cutting knife 6 3-5cm, and the middle part of described nuclear pressure post 106 is provided with jack 107, and jack 107 cooperates with fixed needle 7.

[0040] When cutting, first insert the pears on the fixing pin 7, put the bottom of the pears on the pitting cutter 6, and ensure that the position of the pears is in the middle of the cutting barrel 2 at the same time, as in Example 1, cut and sample, after the sampling is completed , the co...

Embodiment 3

[0042] The difference between the third embodiment and the second embodiment lies in the addition of a baffle plate 4 .

[0043] Such as figure 2 As shown, the blanking port 202 is located between the two equally divided cutters 5, the side wall of the cutting barrel 2 is provided with a plate opening 203, the plate opening 203 communicates with the blanking port 202, and the plate opening 203 There is a baffle plate 4.

[0044] Such as Figure 4 , 5 As shown, the baffle plate 4 includes an inserting plate 401 and a sealing baffle 402, the sealing baffle 402 is connected with the inserting plate 401, and chute is provided on both sides of the blanking port 202, and the inserting plate 401 is connected with the inserting plate 401. The chute cooperates, and the sealing baffle 402 is arranged on the outside of the plate opening 203. The sealing baffle 402 is an arc-shaped structure.

[0045] During cutting, at first partition baffle 4 is taken out from cutting bucket 2, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com