Manufacture method for COB packaged optoelectronic chip with side protection

A technology of photoelectric chips and manufacturing methods, which is applied in the manufacture of circuits, electrical components, final products, etc., can solve problems such as high cost and complicated process, and achieve the effect of reducing product cost, simple process, and large market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment:

[0034] A method for manufacturing a COB package photoelectric chip with side protection, specifically comprising the following steps:

[0035] 1). Prepare the wafer optoelectronic device 1 and PCB board 2 to be processed. The front and back of the wafer optoelectronic device 1 are provided with electrodes, which are the front electrode and the back electrode respectively;

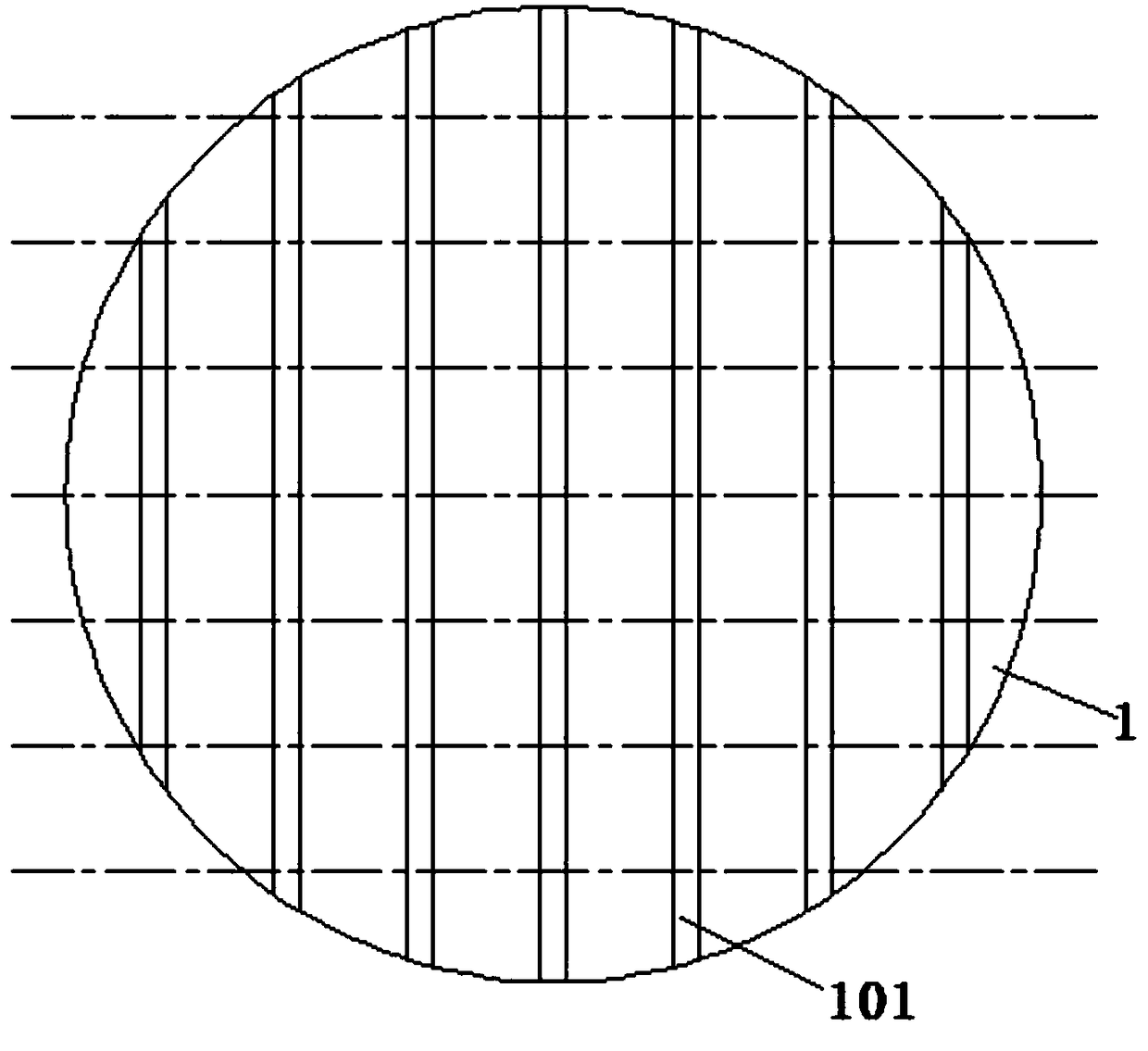

[0036] 2).See figure 1 , half-cut the electrode surface of the wafer optoelectronic device 1, and use a dicing machine to cut along the longitudinal scribing lane reserved on the surface of the front electrode of the wafer optoelectronic device 1 to 1 / 2 of the thickness of the wafer optoelectronic device 1. The width of the cutting groove 101 is between 200-300 microns;

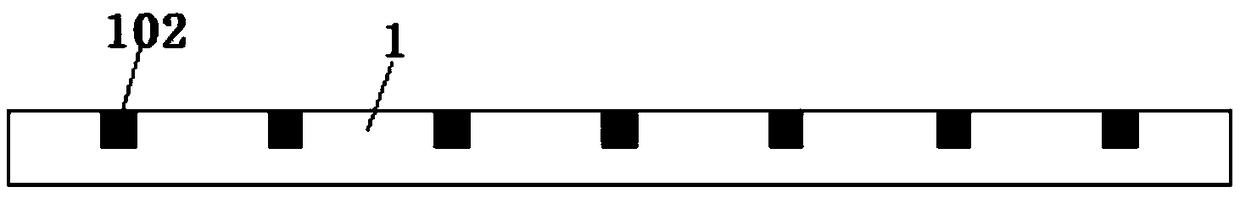

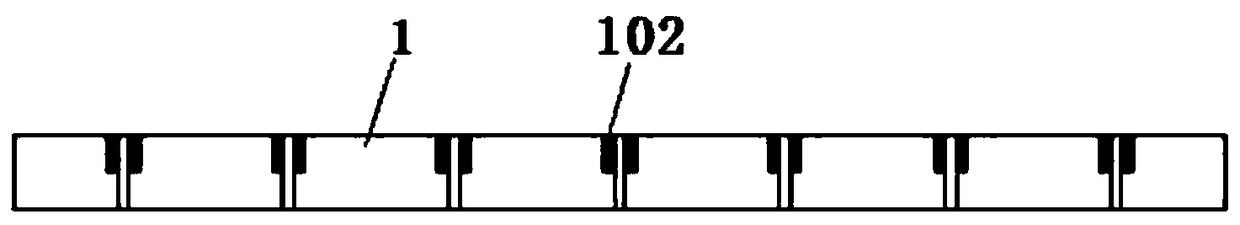

[0037] 3). See figure 2 Inject the insulating potting compound 102 into the cutting groove 101, requiring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com