Installation process of deep foundation pit type transmission line tower grounding device

A technology of transmission lines and grounding devices, which is applied in the direction of circuits, lines/collector parts, towers, etc., can solve problems such as inconvenient installation, additional land acquisition costs, and difficult transportation, so as to avoid the influence of grounding resistance, Avoiding difficult excavation and shortening installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] An installation process of a grounding device for a pole tower of a deep foundation pit type transmission line, comprising the following steps:

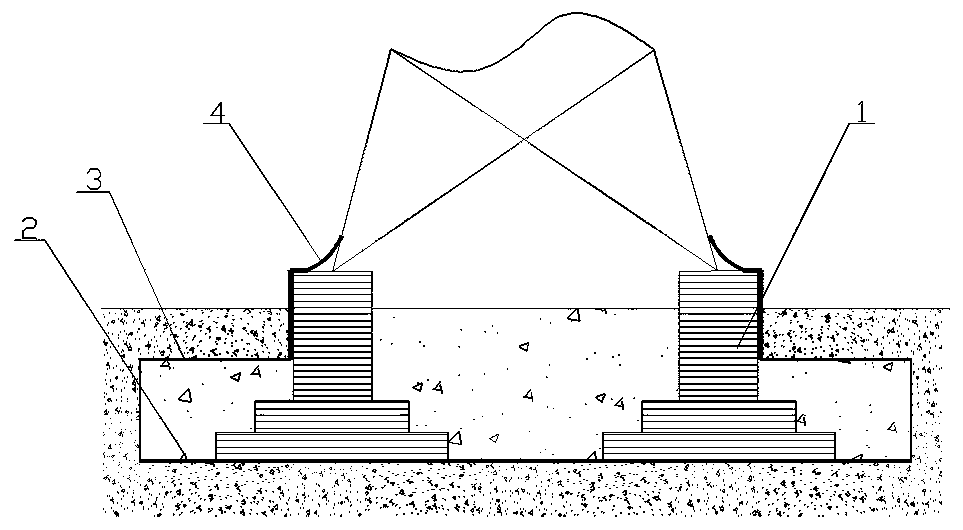

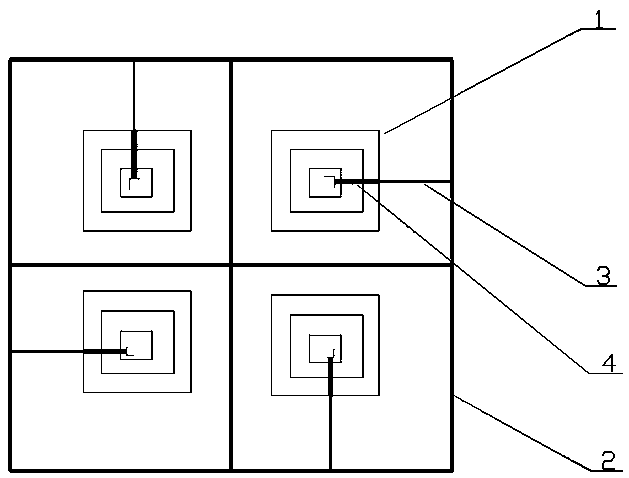

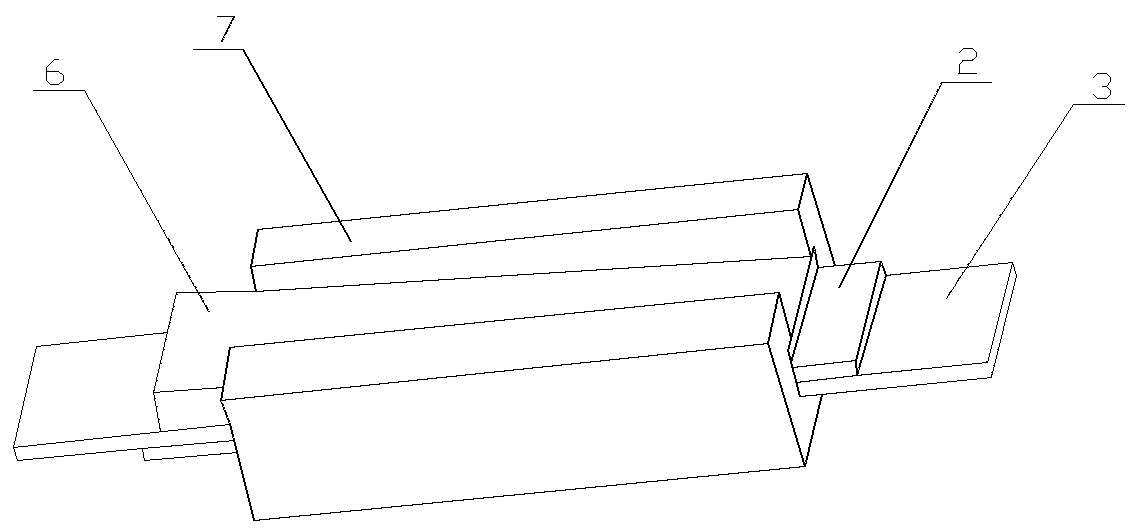

[0024] Step 1. After the excavation of the deep foundation pit is completed, build four transmission line tower foundations 1 in the deep foundation pit, and clean up the sundries in the deep foundation pit when the transmission line tower foundation 1 is completed and the deep foundation pit has not been backfilled , and ensure that the bottom of the deep foundation pit is flat and free of exposed hard objects, and then lay graphite grounding strips 2 around the foundations 1 of the four transmission line towers at the bottom of the deep foundation pit to form a box-shaped structure, and each transmission line tower One side of foundation 1 reserves the joint of graphite grounding belt 2;

[0025] Step 2: U...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap