A temperature control fixture and method for testing the influence of temperature on lens focal length

A lens and focal length technology, applied in TV, electrical components, image communication, etc., can solve the problems of poor application effect, inability to understand and control lens modules, large quality differences, etc., to achieve convenient production, flexible and convenient operation, and manufacturing. and the effect of low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

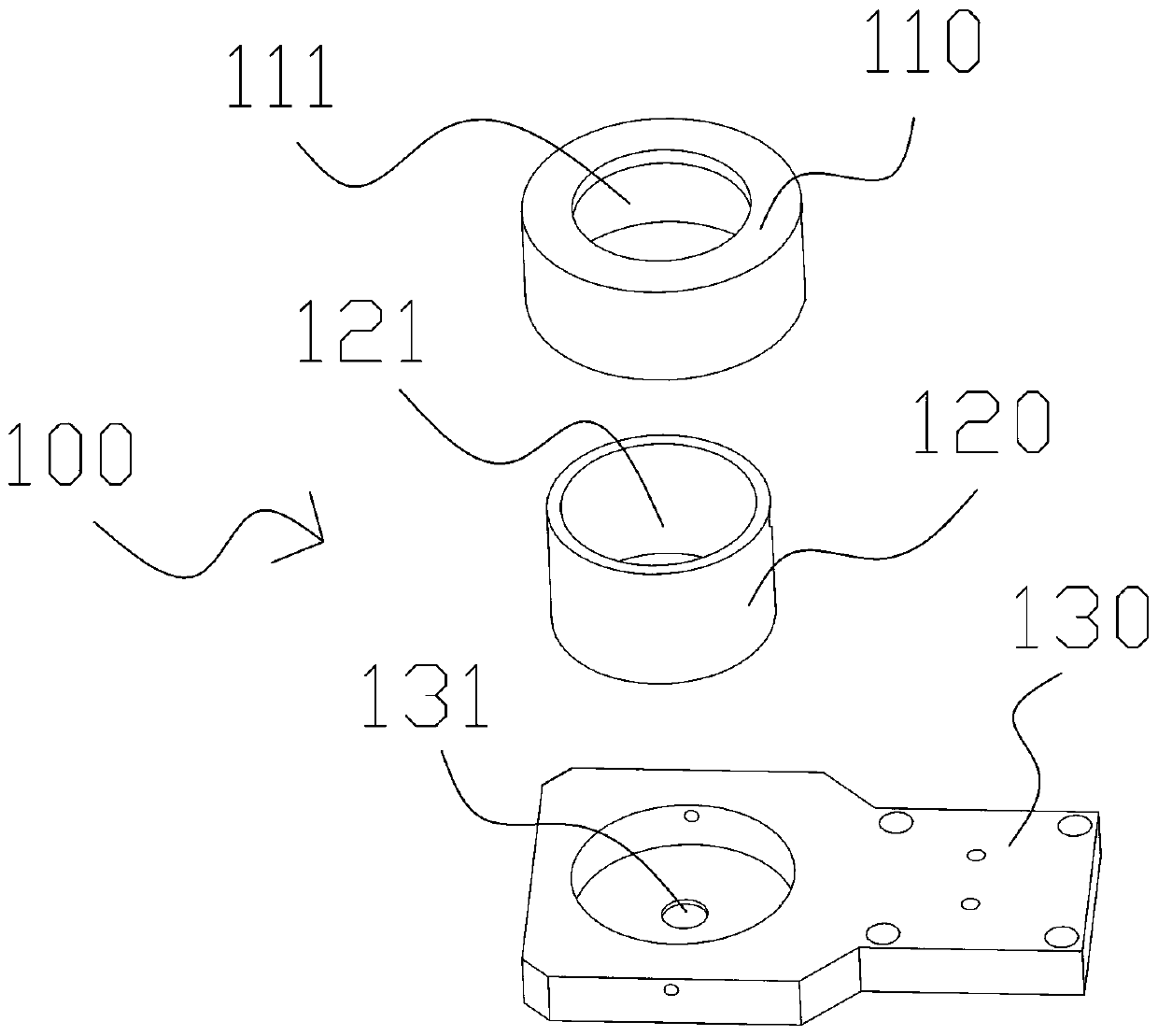

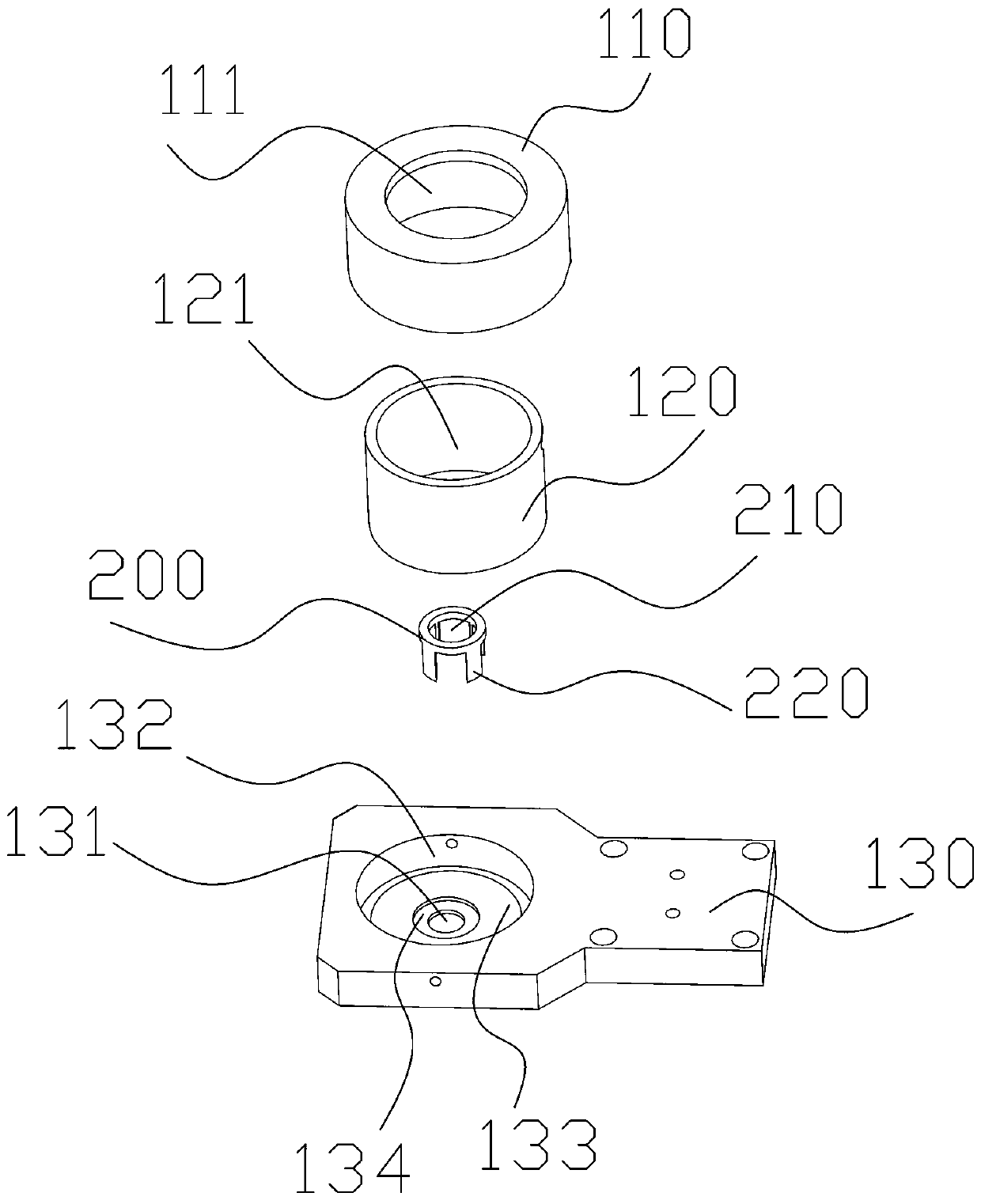

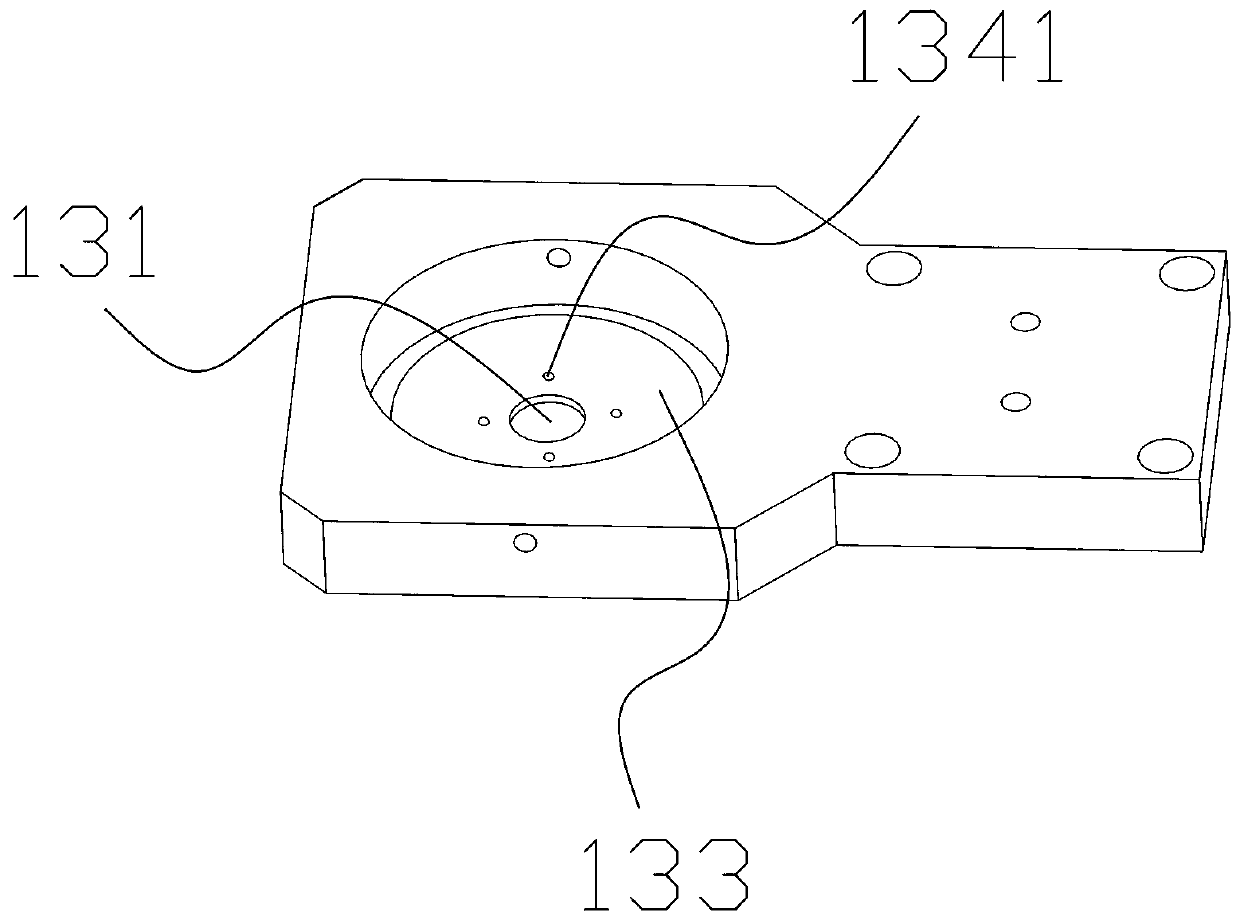

[0043] Such as figure 1 As shown, this embodiment provides a temperature control jig for testing the influence of temperature on the focal length of the lens, including a temperature control regulator and a heater 100. The heater 100 includes a protective cover 110, a heating body 120, and a heat insulation base. 130, the protective cover 110 is provided outside the heating body 120, the protective cover 110 has an inlet port 111, the heating body 120 has a hollow portion 121, the heat insulation base 130 has a light hole 131, the The inlet port 111, the hollow portion 121, and the light through hole 131 are in communication with each other. The heating body 120 is electrically connected to the temperature control regulator, and the temperature control regulator is used to change the temperature of the heating body 120.

[0044] Specifically, the heating body 120 is placed on the heat-insulating base 130, the hollow part 121 is opposite to the light-passing hole 131, that is, the ...

Embodiment 2

[0058] This embodiment provides a method for testing the influence of temperature on the focal length of a lens, and the used testing device includes: an optical focal length adjustment device 3, an optical resolution test device, and the temperature control fixture described in embodiment 1, such as Figure 5 As shown, the optical focus adjustment device 3 includes a first fine-tuning platform 31 and a second fine-tuning platform 32, and the method includes the following steps:

[0059] Put the lens to be tested into the heater 100 from the inlet port 111, fix the heater 100 on the first fine-tuning platform 31, and place the photosensitive chip on the second fine-tuning platform 32 , Placing the optical focal length adjustment device 3 on a testing machine platform of the optical resolution testing device;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com