Laser flattening method for micro-deformed plate

A micro-deformation and plate technology, applied in the field of mechanical processing and manufacturing, can solve the problems of plate thermal damage, low precision, low efficiency, etc., and achieve the effect of improving leveling accuracy and efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

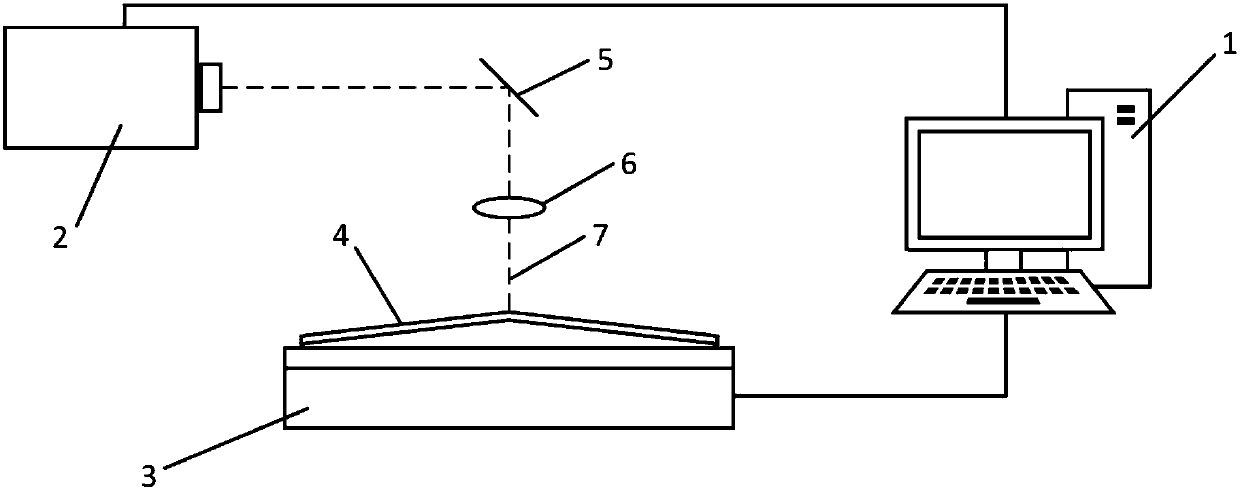

[0025] combined with Figure 1-6 , to further describe the present invention. The laser leveling device for micro-deformed plates is mainly composed of a numerical control PC (1), a laser (2), a three-dimensional numerical control platform (3), a plate to be leveled (4), a mirror (5), a focusing mirror (6), a laser beam ( 7) composition, such as figure 1 shown.

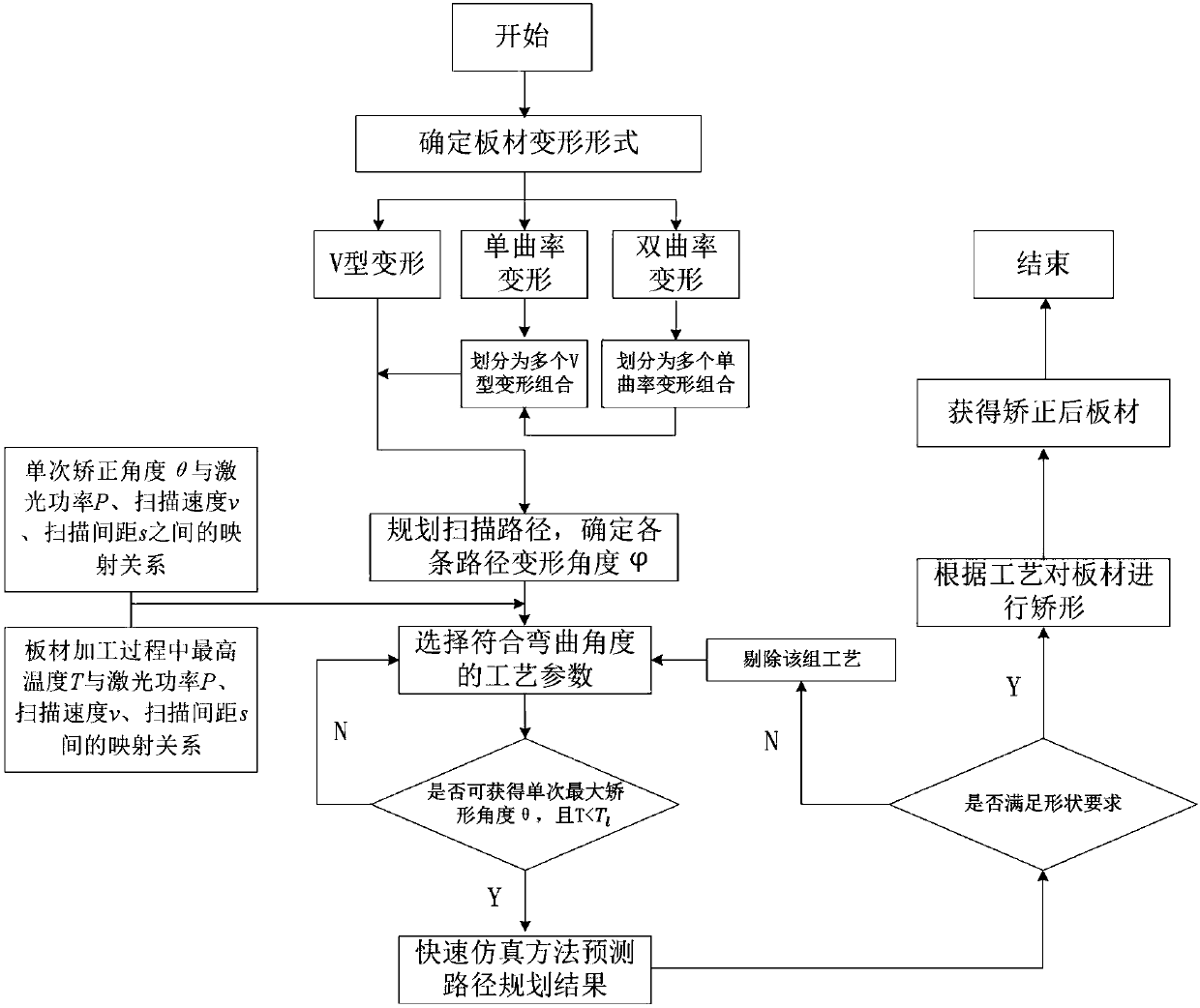

[0026] The steps of laser leveling of deformed sheet are as follows: figure 2 As shown, the specific description is as follows:

[0027] First, according to the deformation of the plate, determine its main deformation form, and plan the scanning path according to the deformation form, and determine the leveling angle required for each scanning path

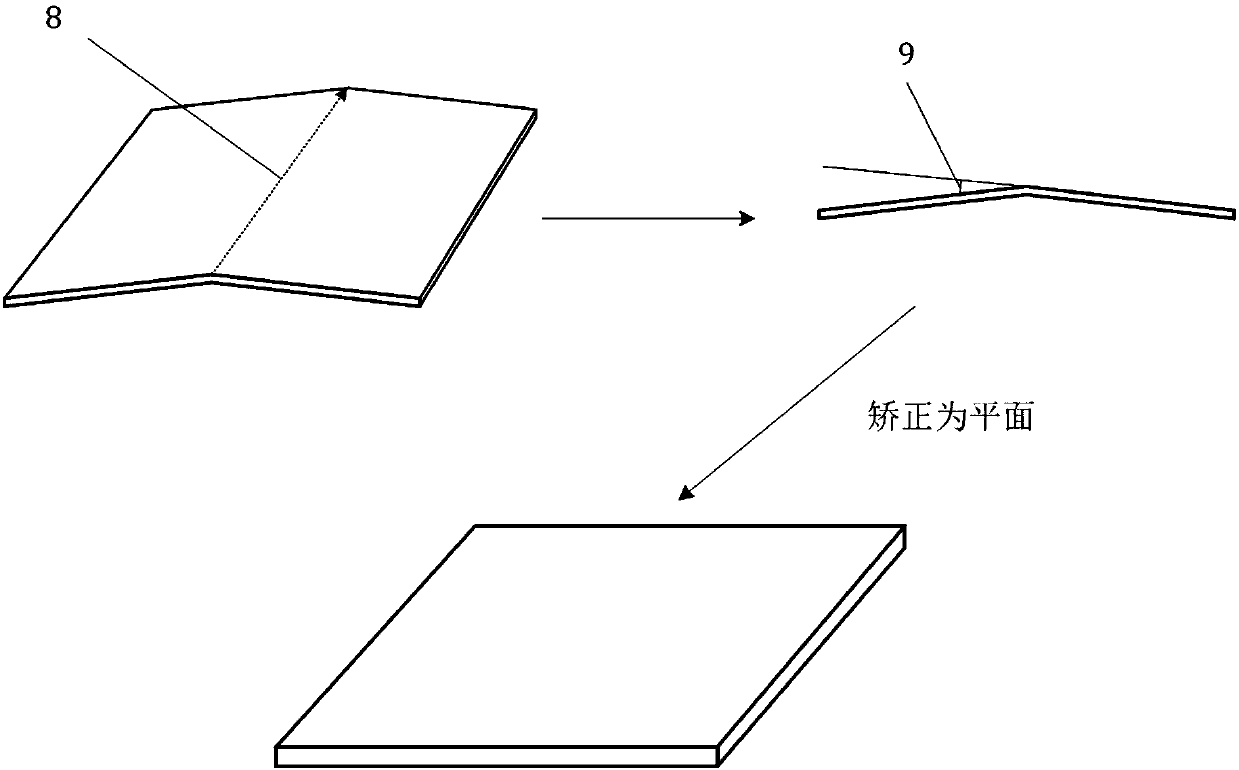

[0028] The planning scheme of the scanning path is: for the V-shaped deformed plate, such as image 3 As shown, the laser is used to scan along the V-shaped surface scanning path (8) to determine the required leveling angle of the V-shaped surface (10), the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com