Welding gun clamping device for double TIG high-speed welding process

A welding process and clamping device technology are applied in the field of adjustment of the position and attitude of the welding torch during the double TIG high-speed welding of stainless steel thin-walled tubes, achieving the effects of strong practicability, easy promotion and error reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: For specifications of The 304 stainless steel pipe adopts double TIG welding process for welding production. Through the process test, a good weld shape can be obtained, and the welding speed can reach 3.0m / min. Among them, the main current is 293A, the auxiliary current is 150A, and the main arc is argon. The flow rate is 10L / min, the auxiliary arc argon gas flow rate is 15L / min, the inclination angle of the main tungsten pole is 84°, the inclination angle of the auxiliary tungsten pole is 80°, the arc length of the main arc is 1.2mm, and the arc length of the auxiliary arc is 2.5mm. The tip angle of the pole is 30°, the tip angle of the auxiliary tungsten pole is 60°, the diameter of the tungsten pole is 3.2mm, and the distance between the tungsten poles is 20mm. On the basis of the combination of the above optimal parameters, through measurement, the outer diameter of the ceramic nozzle is 18mm, the center distance of the through hole of the jacket is 23.5...

Embodiment 2

[0037] Example 2: For specifications of The 304 stainless steel pipe adopts double TIG welding process for welding production. Through the process test, a good weld shape can be obtained, and the welding speed can reach 3.0m / min. Among them, the main current is 180A, the auxiliary current is 160A, and the main arc is argon The flow rate is 10L / min, the auxiliary arc argon gas flow rate is 15L / min, the inclination angle of the main tungsten pole is 86°, the inclination angle of the auxiliary tungsten pole is 80°, the arc length of the main arc is 2mm, the arc length of the auxiliary arc is 3mm, the main tungsten pole tip The angle is 50°, the tip angle of the auxiliary tungsten pole is 60°, the diameter of the tungsten pole is 3.2mm, and the distance between the tungsten poles is 16.5mm. Based on the combination of the above optimal parameters, through measurement, the outer diameter of the ceramic nozzle is 18mm, the center distance of the through hole of the jacket is 20.5mm...

Embodiment 3

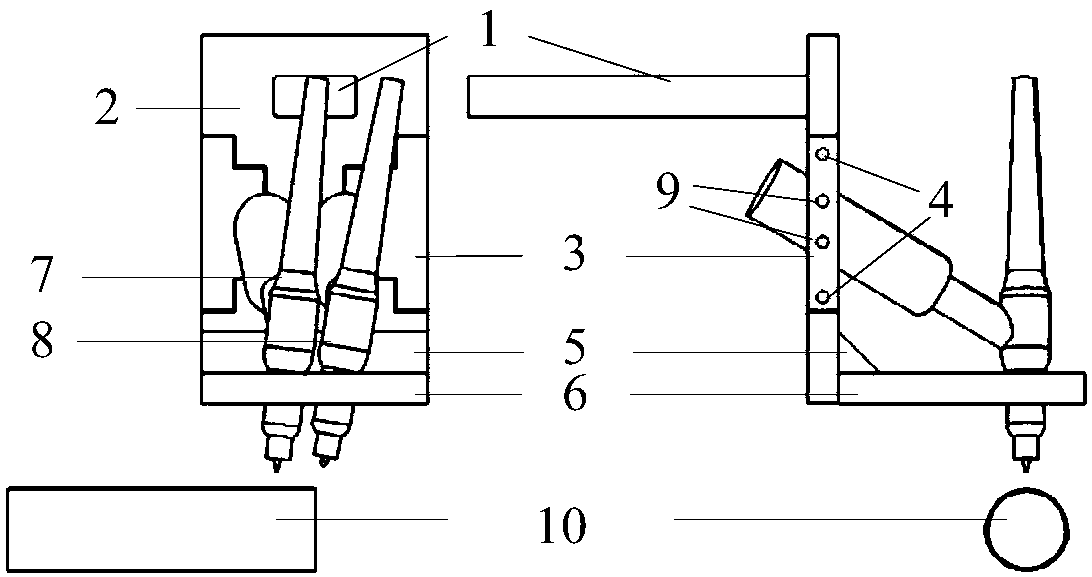

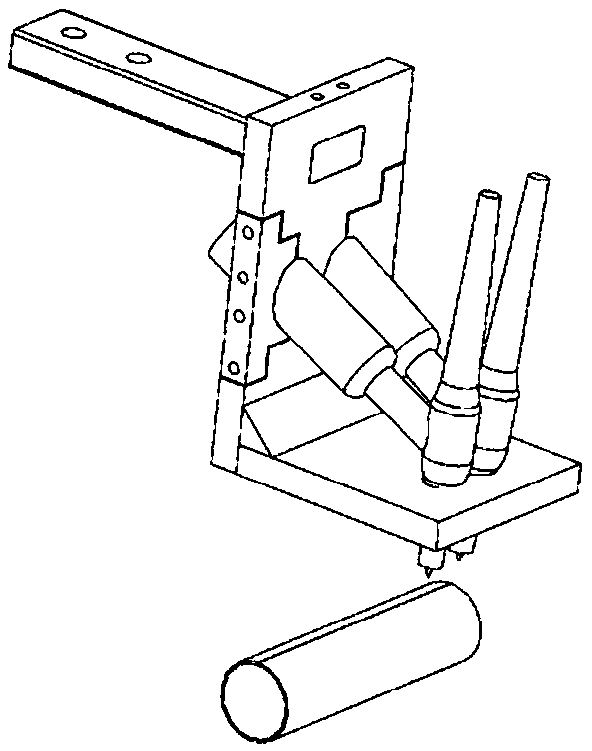

[0039] A welding torch clamping device for a double TIG high-efficiency welding process, comprising: a right-angle bracket, two through holes for fixing the nozzle of the welding torch are arranged on the horizontal surface of the right-angle bracket, and a handle clamp is arranged on the vertical surface of the right-angle bracket Holding plate 2 and clamping plate buckle plate 3, after the handle clamping plate 2 and clamping plate buckle plate 3 are closed, two holes for fixing the handles of welding torches 7 and 8 are formed, and the handle clamping plate 2 is also provided with The support 1, the support 1 and the horizontal plane of the right-angle bracket are respectively located on both sides of the vertical plane of the right-angle bracket.

[0040] The fastening device 4 is a threaded hole arranged on the side of the buckle plate of the clamping plate 2 .

[0041] A jacket 6 matching the nozzle of the welding torch is arranged on the through hole.

[0042] The abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com