Plastic pipe molding method

A technology for plastic pipes and molding methods, which is applied to tubular articles, other household appliances, household appliances, etc., can solve the problems affecting the working efficiency of plastic pipe forming machines, the inability to achieve stable output of plastics, and the unreasonable structure of the heating system. Improve heating and melting effect, improve heating quality, and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

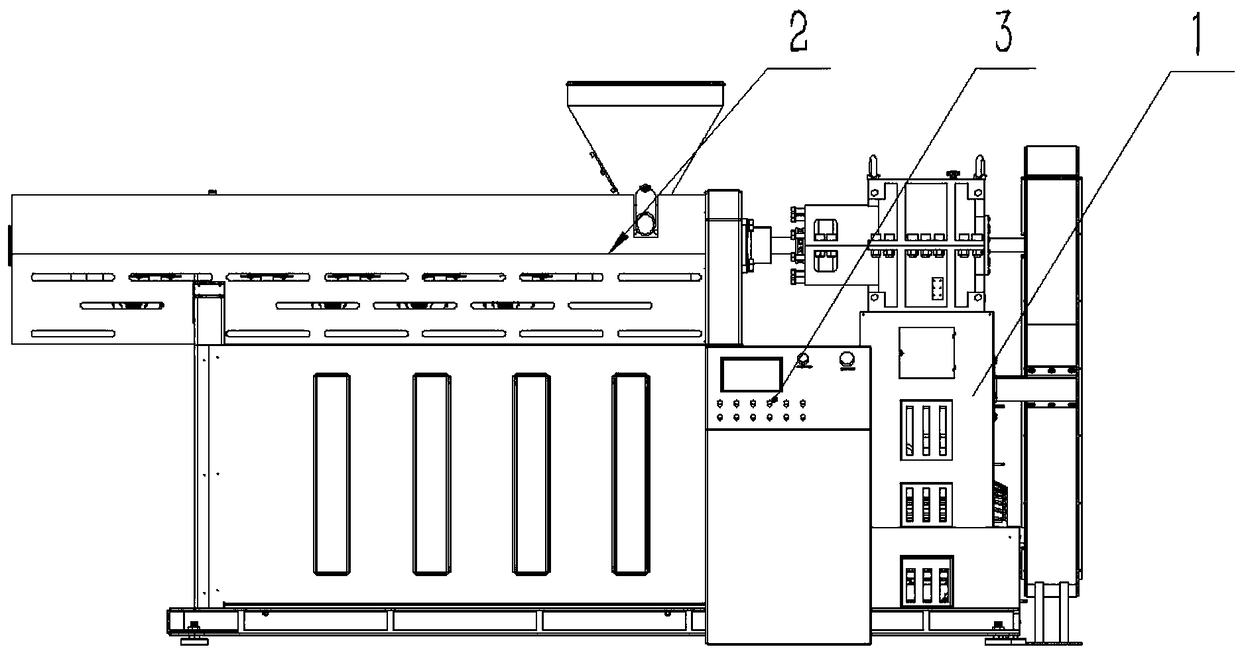

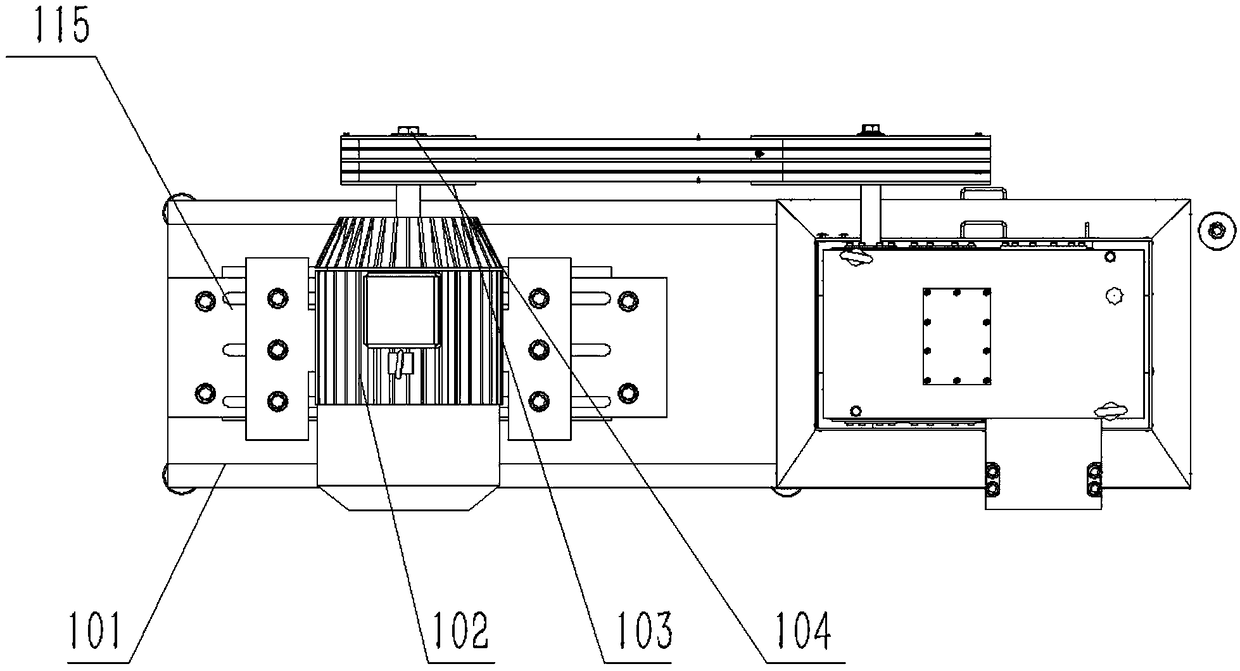

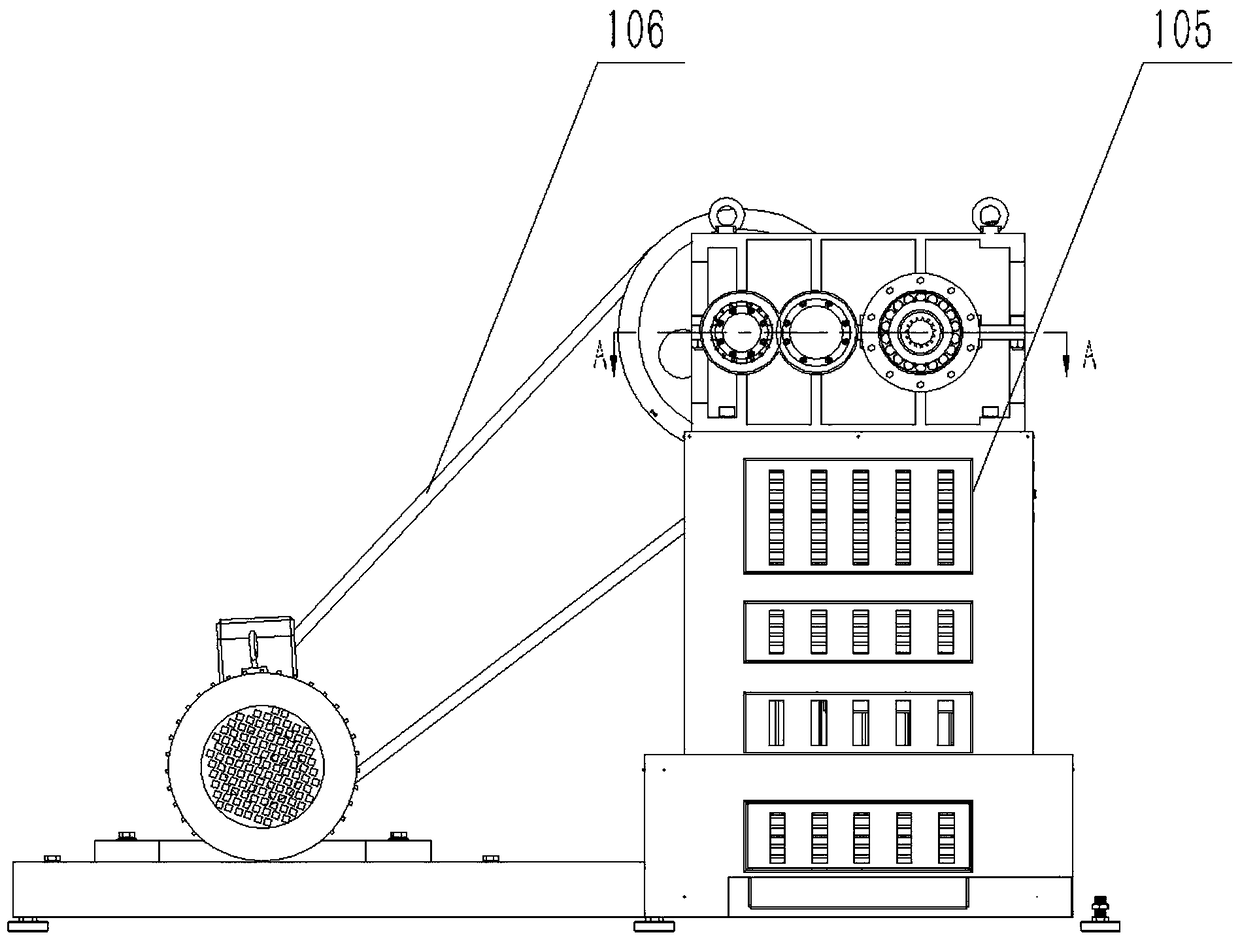

[0041] Such as figure 1As shown, a plastic pipe molding equipment includes a transmission mechanism 1, an extrusion molding mechanism 2 and an operating table 3, an extrusion molding mechanism 2 is connected to one side of the transmission mechanism 1, and the front end of the extrusion molding mechanism 2 is provided with Operating console 3, the operating console 3 includes an electrical cabinet and an operating panel, and a control panel is installed above the electrical cabinet; the electrical cabinet is used to place electrical components in the equipment for easy maintenance and wiring, and the operating panel includes A button module for setting the action of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap