Room-temperature-cured high-pressure epoxy pipeline and preparation method thereof

A technology of curing at room temperature and high-pressure ring, applied in the direction of tubular objects, other household appliances, applications, etc., can solve the problems of low activity of epoxy resin, energy loss, environmental impact, etc., to save production costs and energy, reduce pollution damage, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

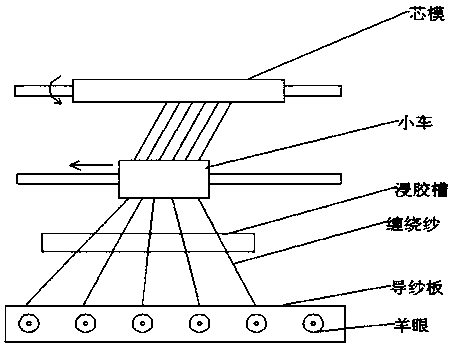

[0054] Such as figure 1 , figure 2 Shown: a kind of normal temperature curing high-pressure epoxy pipeline preparation method, it comprises the following steps:

[0055] (a) Epoxy resin curing glue system configuration at room temperature;

[0056] The specific materials and configuration methods are as follows:

[0057] With the ratio of epoxy resin: curing agent: defoamer=100:13.5:0.2 (ratio is in parts by weight), weigh 50KG epoxy resin, 5~6.75KG curing agent, 0.05~0.1KG defoamer respectively, Stir and mix the epoxy resin and curing agent for 2 minutes, then add the defoamer, stir and mix for 5 minutes, and let stand for 5 minutes.

[0058] In the present invention, the epoxy resin is a bisphenol A type epoxy resin, the curing agent is triethylenetetramine, and the defoaming agent is an acrylate polymer.

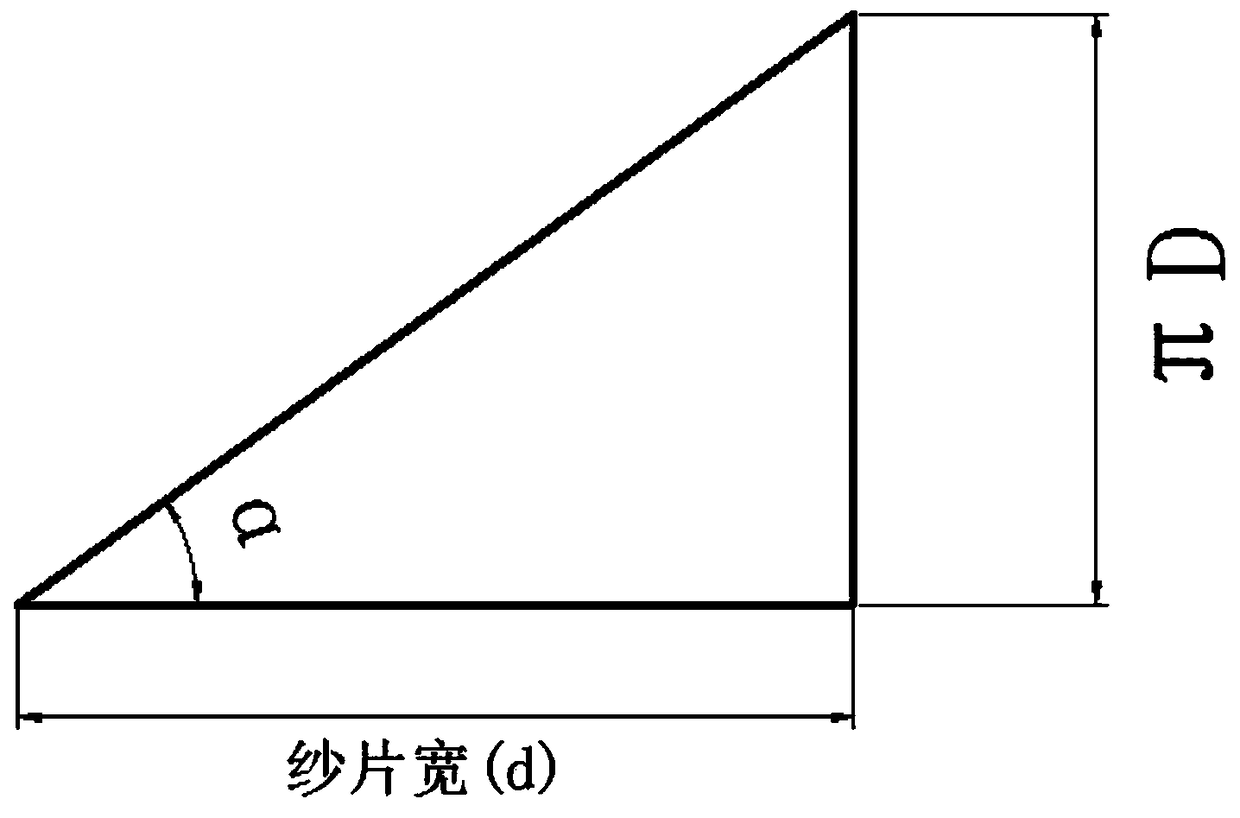

[0059] (b) Winding control; the specific method is:

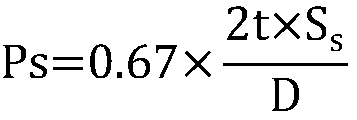

[0060] Calculate wall thickness based on pressure requirements:

[0061]

[0062] (Where Ps is the static pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com