Zinc diricinoleate composite alkaloid cleaning agent and preparation method

A technology of zinc ricinoleate and alkaloids, which is applied in the field of cleaning agents, can solve the problems of long use time, slow effect, and the lack of decomposing odor of cleaning agents, and achieve the effects of low corrosion, low environmental pollution damage, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

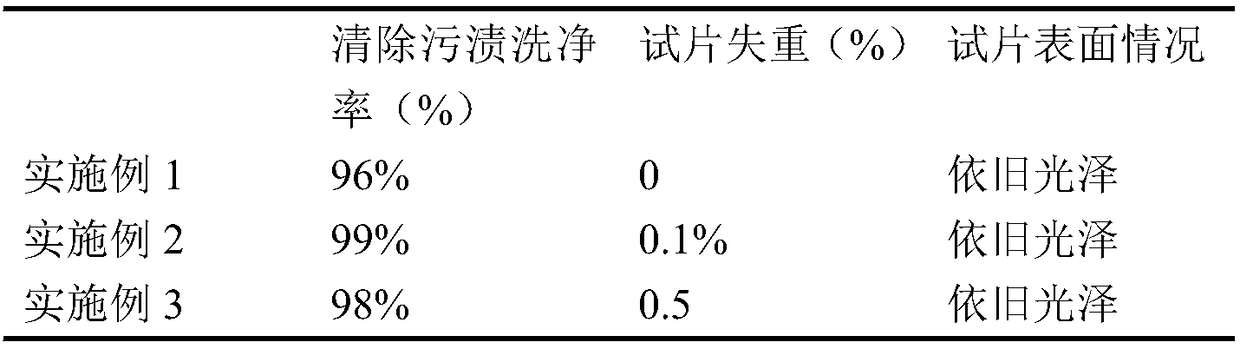

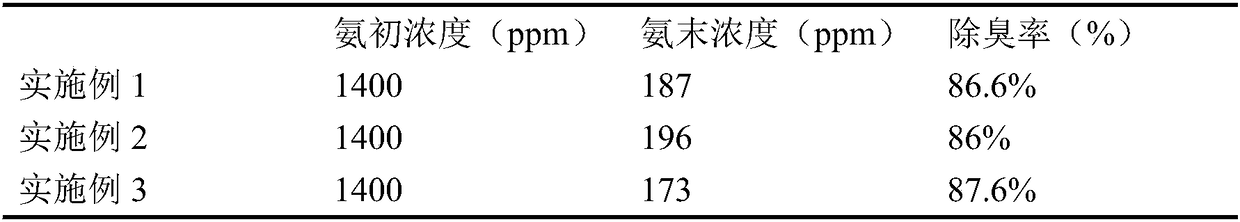

Examples

Embodiment 1

[0022] A zinc ricinoleate composite alkaloid cleaning agent includes the following components: zinc ricinoleate 5%, tea alkaloid 3%, surfactant 5%, and the balance is deionized water.

[0023] (1) Add deionized water to the reaction kettle, add surfactant under stirring, and stir well for 20 minutes;

[0024] (2) Adding tea alkaloids and zinc ricinoleate in sequence, mixing and stirring for 15 minutes, fully stirring for 25 minutes, and filling after standing for 24 hours to obtain a zinc ricinoleate composite alkaloid cleaning agent.

[0025] The speed of full stirring is 240 revolutions per minute.

Embodiment 2

[0027] A zinc ricinoleate composite alkaloid cleaning agent, which mainly includes the following components: zinc ricinoleate 3%, coptis alkaloid 1%, anionic surfactant 2%, nonionic surfactant 1%, sodium hydroxide 0.2 %, sulfonic acid 0.05%, the balance is deionized water.

[0028] A preparation method of zinc ricinoleate composite alkaloid cleaning agent, the specific steps are as follows:

[0029] (1) Add deionized water to the reaction kettle, add anionic and non-ionic surfactants while stirring, and stir well for 20 minutes;

[0030] (2) Sodium hydroxide is premixed in water at a ratio of 1:100, and sulfonic acid is added to fully dissolve it, and the pH value is tested at 7-12 (as required by performance), and the premix is prepared for use;

[0031] (3) Add the alkaloids and zinc ricinoleate in turn, mix and stir for 15 minutes, then add the premix, fully stir for 25 minutes, and let it stand for 24 hours before filling to obtain the zinc ricinoleate composite alkaloid cleanin...

Embodiment 3

[0034] A zinc ricinoleate composite alkaloid cleaning agent, which mainly includes the following components: zinc ricinoleate 5%, garlic alkaloid 1%, cationic surfactant 3%, hydrochloric acid 11%, acidic thickener 1%, and the rest The amount is deionized water.

[0035] A preparation method of zinc ricinoleate composite alkaloid cleaning agent, the specific steps are as follows:

[0036] (1) Add deionized water to the reaction kettle, add cationic surfactant under stirring, and fully stir for 20 minutes;

[0037] (2) Slowly add hydrochloric acid and stir, add garlic alkaloids and zinc ricinoleate in turn, mix and stir for 15 minutes, then add acidic thickener and stir well for 15 minutes, then fill to obtain zinc ricinoleate composite alkaloid cleaning Agent

[0038] The speed of full stirring is 240 revolutions per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com