Fully synthetic water-based cutting fluid

A cutting fluid, fully synthetic technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of extreme pressure performance, anti-rust cleaning performance can not meet the working requirements of cutting fluid, achieve good storage stability, improve slow eclipse, reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

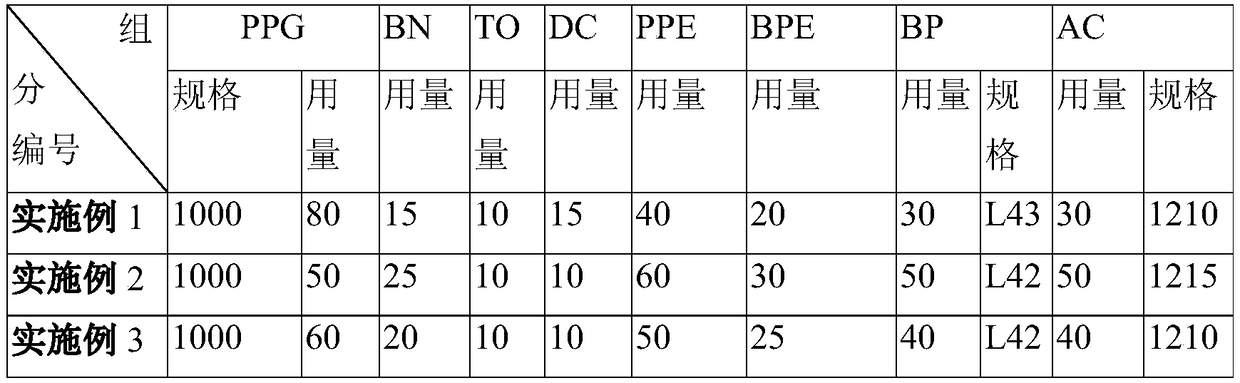

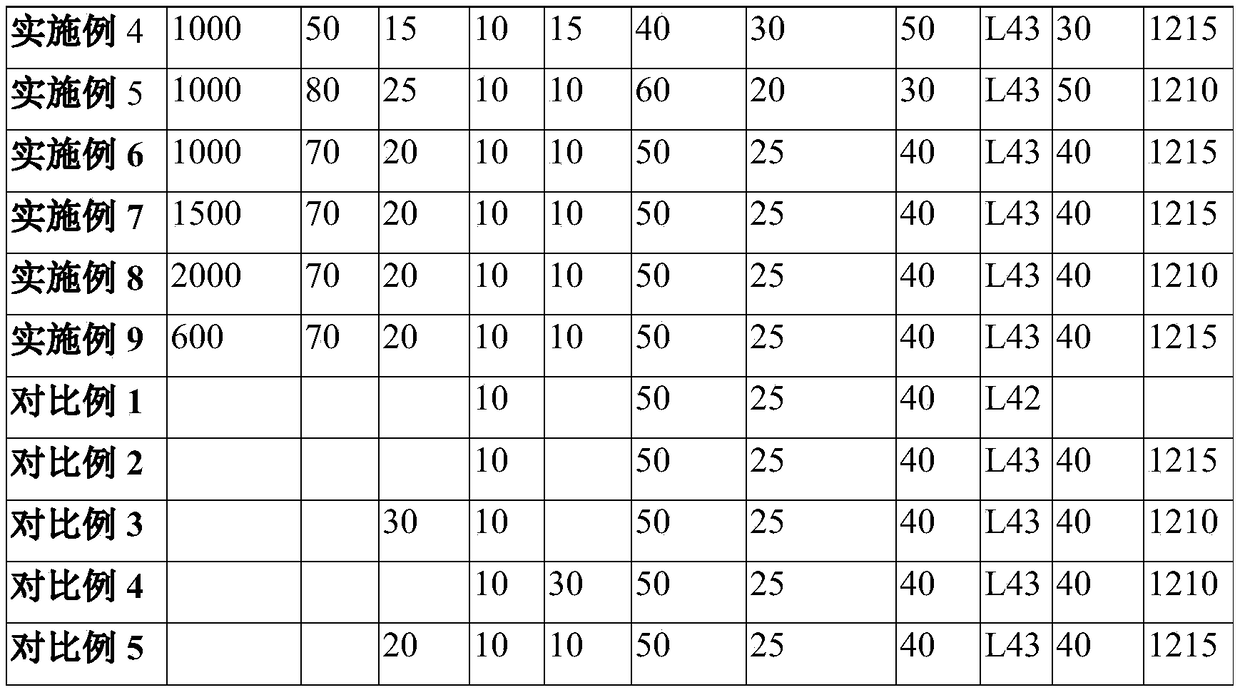

[0020] Embodiment formula sees the following table (unit: weight part)

[0021]

[0022]

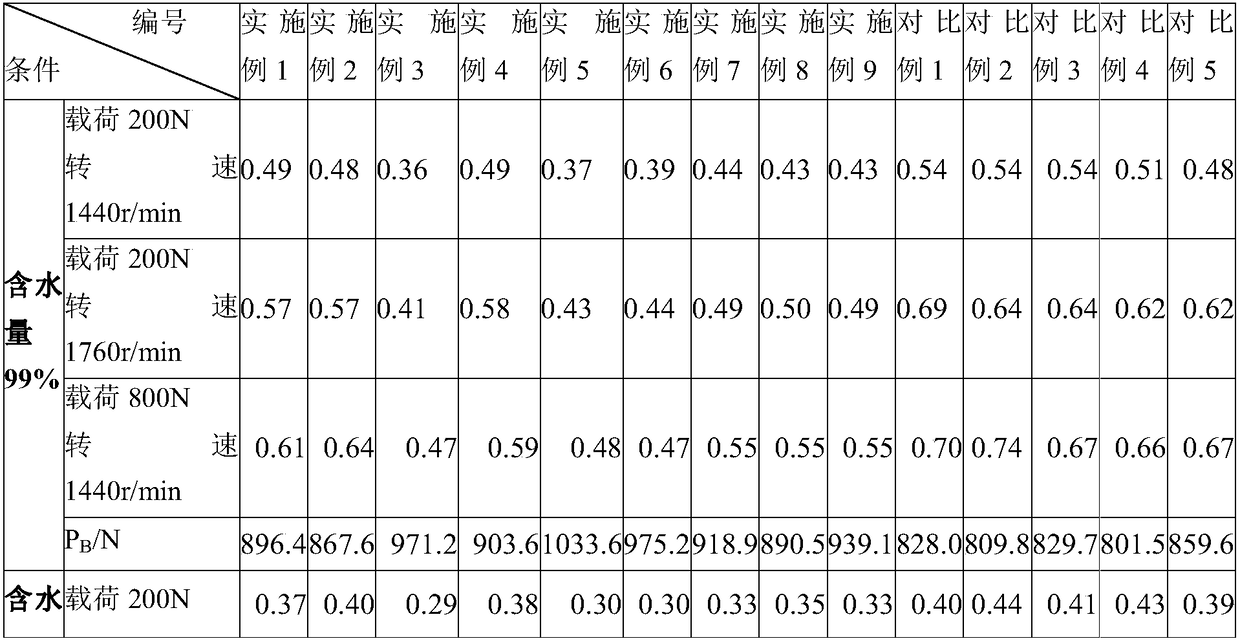

[0023] The cutting fluids obtained in Examples and Comparative Examples were diluted with deionized water to water contents of 99% and 95% (wt), respectively, before use.

Embodiment 2

[0032] Detecting Example 2 Transparency, defoaming property, corrosion test, rust resistance test

[0033] According to the method and standard (L-MAH) stipulated in GBT6144-2010, the cutting fluid (diluted to water content 95%) that each embodiment and comparative example obtains is carried out transparency, pH value, defoaming property, corrosion test, antirust test, the results are as follows.

[0034]

[0035] Experimental result shows, the cutting fluid that embodiment obtains can all be qualified in every test, in comparative example, each comparative example is all unqualified in defoaming property test, and all the other comparative examples fail all to pass corrosion test and antirust property. test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com