Technology for producing multi-vein-mark low-grade split leather into high-grade wax leather

A low-grade, two-layer leather technology, applied in the field of leather, can solve the problems of limited selling price, darkening of leather surface, high price of top layer leather, etc., and achieve the effect of huge added value and high profit margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A process for making high-grade waxy leather from low-grade split leather with many veins, comprising the following steps:

[0039] S1 Drying: Take the dyed blood tendon leather material and put it in the oven to bake for 24 hours to obtain the dried leather material;

[0040] S2 softening: put the dried leather material obtained in step S1 into a steel drum, vibrate and soften for 5 hours, and obtain a softened leather embryo;

[0041] S3 dermabrasion: use 180# sandpaper to sand the front of the soft leather embryo once, use 280# sandpaper to sand the blood tendon side of the soft leather embryo once, and use 220# sandpaper to sand the soft leather embryo The whole piece of skin of the embryo is frosted once;

[0042] S4 second softening: put the skin embryo after grinding into the steel drum, vibrate and soften again for 1 hour;

[0043] S5 roller coating: put the skin embryo after the second softening into the roller coating machine and roll oil wax;

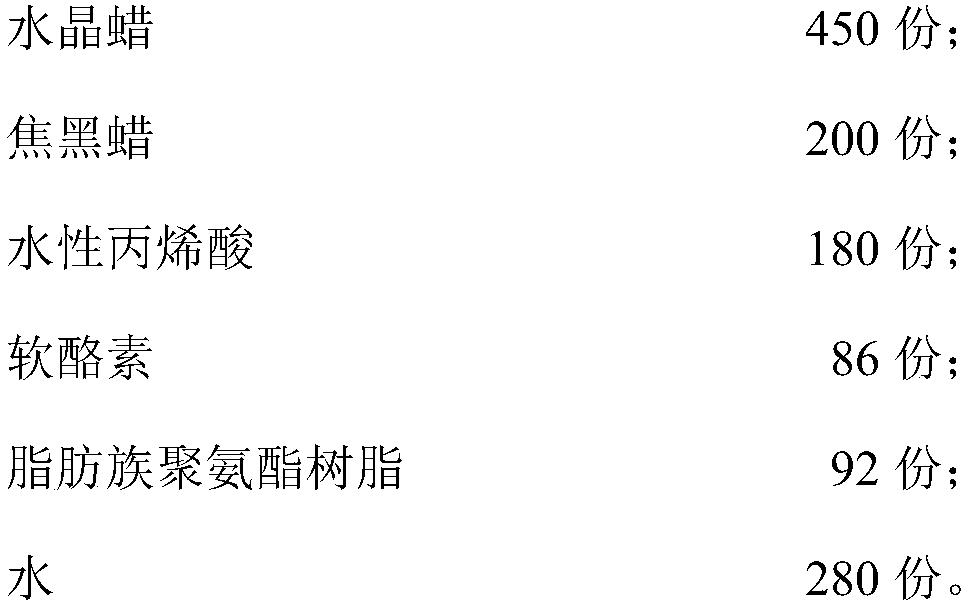

[0044] S6 o...

Embodiment 2

[0059] A process for making high-grade waxy leather from low-grade split leather with many veins, comprising the following steps:

[0060] S1 Drying: Take the dyed blood tendon leather material and put it in the oven to bake for 27 hours to obtain the dried leather material;

[0061] S2 softening: Put the dried leather material obtained in step S1 into a steel drum, vibrate and soften for 6 hours, and obtain the softened leather embryo;

[0062] S3 dermabrasion: use 180# sandpaper to sand the front of the soft leather embryo once, use 280# sandpaper to sand the blood tendon side of the soft leather embryo once, and use 220# sandpaper to sand the soft leather embryo The whole piece of skin of the embryo is frosted once;

[0063] S4 second softening: put the skin embryo after grinding into the steel drum, vibrate and soften again for 1 hour;

[0064] S5 roller coating: put the skin embryo after the second softening into the roller coating machine and roll oil wax;

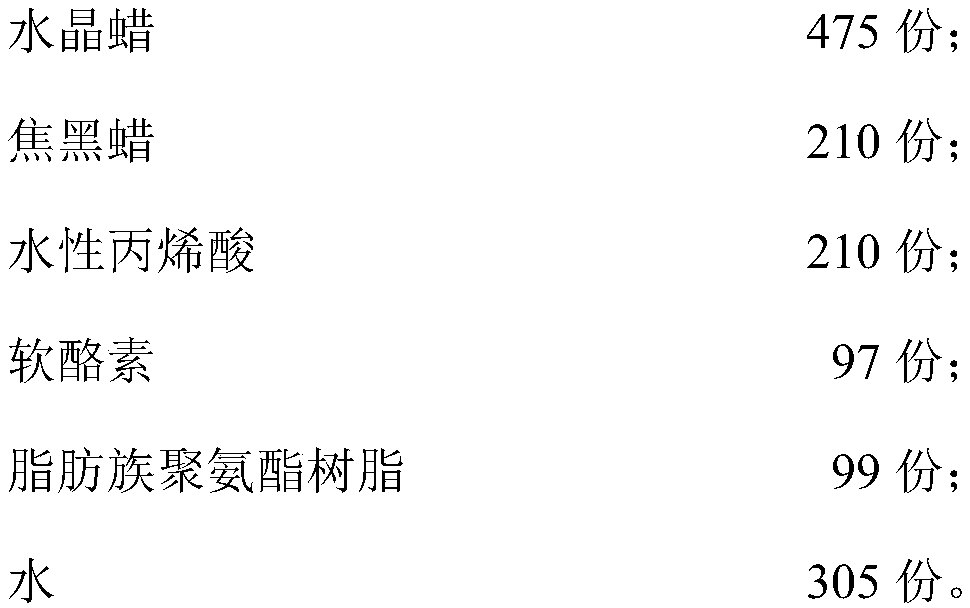

[0065] S6...

Embodiment 3

[0080] A process for making high-grade waxy leather from low-grade split leather with many veins, comprising the following steps:

[0081] S1 Drying: Take the dyed blood tendon leather material and put it in the oven to bake for 30 hours to obtain the dried leather material;

[0082] S2 softening: put the dried leather material obtained in step S1 into a steel drum, vibrate and soften for 7 hours, and obtain the softened leather embryo;

[0083] S3 dermabrasion: use 180# sandpaper to sand the front of the soft leather embryo once, use 280# sandpaper to sand the blood tendon side of the soft leather embryo once, and use 220# sandpaper to sand the soft leather embryo The whole piece of skin of the embryo is frosted once;

[0084] S4 second softening: put the skin embryo after grinding into the steel drum, vibrate and soften again for 1 hour;

[0085] S5 roller coating: put the skin embryo after the second softening into the roller coating machine and roll oil wax;

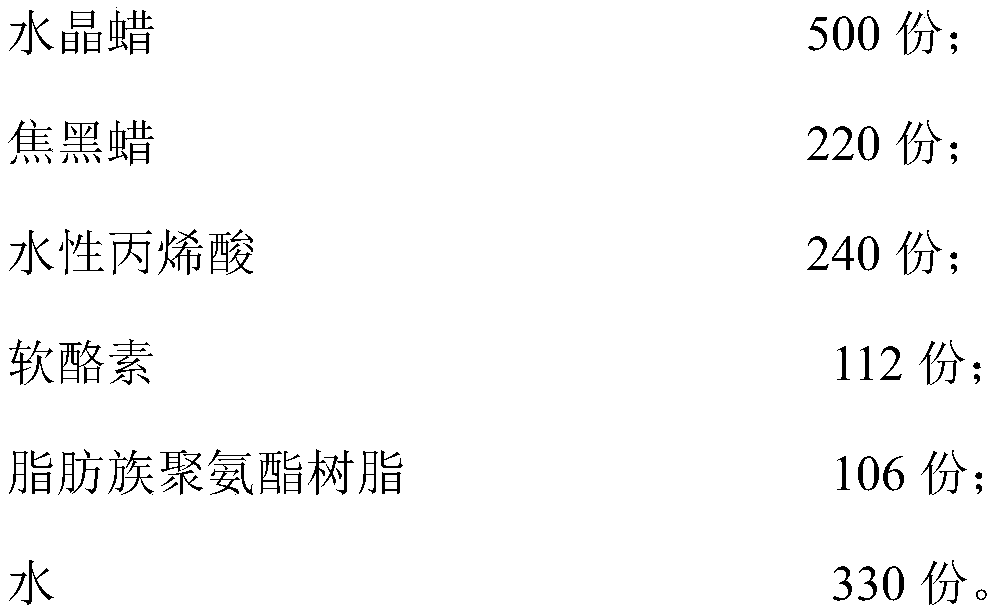

[0086] S6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com