A method for connecting blast furnace tuyere and iron mouth

A blast furnace and iron hole technology, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve problems such as difficulty in judging blast furnace tuyere and iron mouth penetration, low efficiency, etc., to shorten the oxygen burning time, speed up the cleaning process, and reduce operations. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0021] A method for penetrating blast furnace tuyeres and iron ports, comprising the following steps:

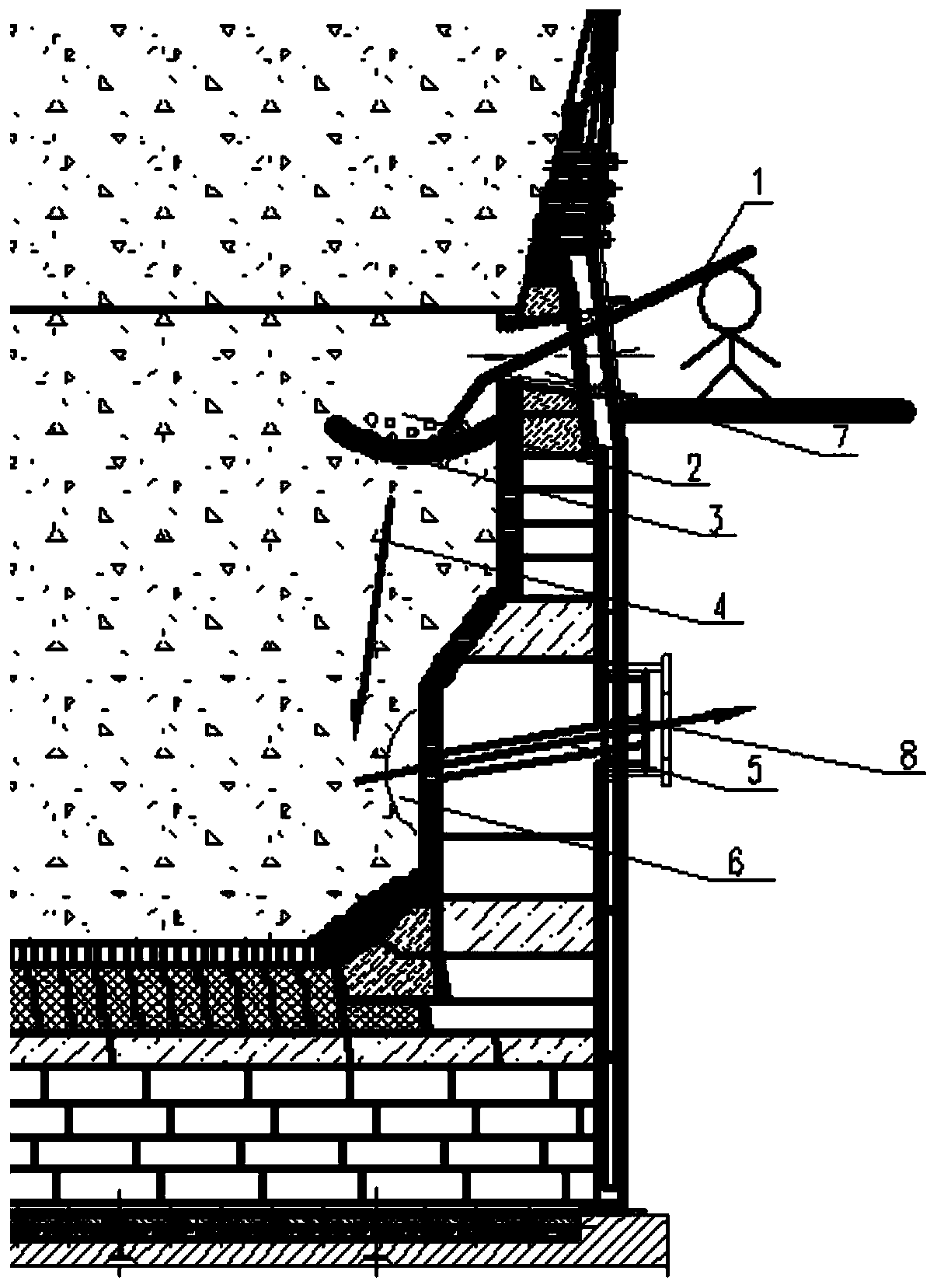

[0022] 1) Drill through the mud bag 6 at the 8 places of the blast furnace taphole with a blast furnace taphole opening machine, so that the taphole tunnel 5 of the blast furnace taphole 8 is unblocked;

[0023] 2) remove the middle cover and the small cover of the tuyere 7 of the blast furnace, and remove the coke at the front end of the tuyere 7 of the blast furnace to form a basin;

[0024] 3) Load aluminum ingot 3 and coke 2 in sequence at the front end of blast furnace tuyere 7, first spread aluminum ingot 3 on the iron slag, and then spread coke 2 on the aluminum ingot 3 to form a F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com