Flue gas waste heat recycling device for waste incineration power plant

A flue gas waste heat and waste incineration technology, applied in the direction of cleaning heat transfer devices, heat exchangers, incinerators, etc., can solve the problems of reducing heat exchange efficiency, flue gas blockage, affecting flue gas emissions, etc., to achieve efficient heat exchange, Ensure efficient heat exchange and enhance the effect of the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

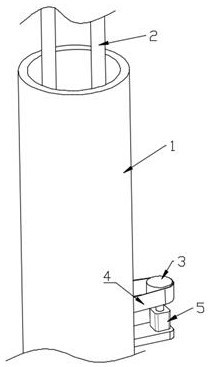

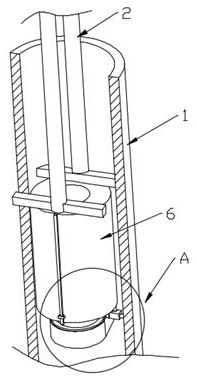

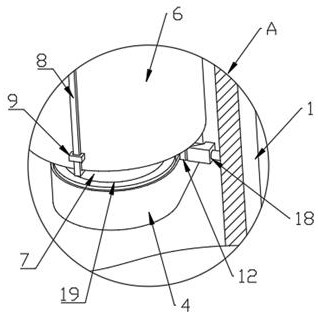

[0031] refer to Figure 1-7 , a device for recovering and utilizing flue gas waste heat in a waste incineration power plant, comprising an exhaust pipe 1 for discharging flue gas, the interior of the exhaust pipe 1 is fixedly connected with a heat-absorbing block 6, and the heat-absorbing block 6 is provided with a channel in the vertical direction, and the air-absorbing The heat block 6 is provided with a liquid storage chamber for loading heat-conducting liquid. Two water pipes 2 are fixedly connected to the upper end of the heat-absorbing block 6. Both water pipes 2 communicate with the liquid storage chamber, and the two water pipes 2 communicate with an external water tank. A water pipe 2 is provided with a water pump, which can replace the liquid in the heat-absorbing block 6 to realize heat exchange. There is a gap between the heat-absorbing bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com