Concrete-filled steel tubular column-concrete-filled steel tubular beam joint connection structure

A technology of concrete-filled steel pipe columns and concrete-filled steel pipes, which is applied to truss structures, columns, joists, etc., can solve problems such as difficulty in cross-installation of bolts, heavy welding workload, and high technical requirements for workers, and achieve efficient and convenient on-site construction and welding work Large quantity and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

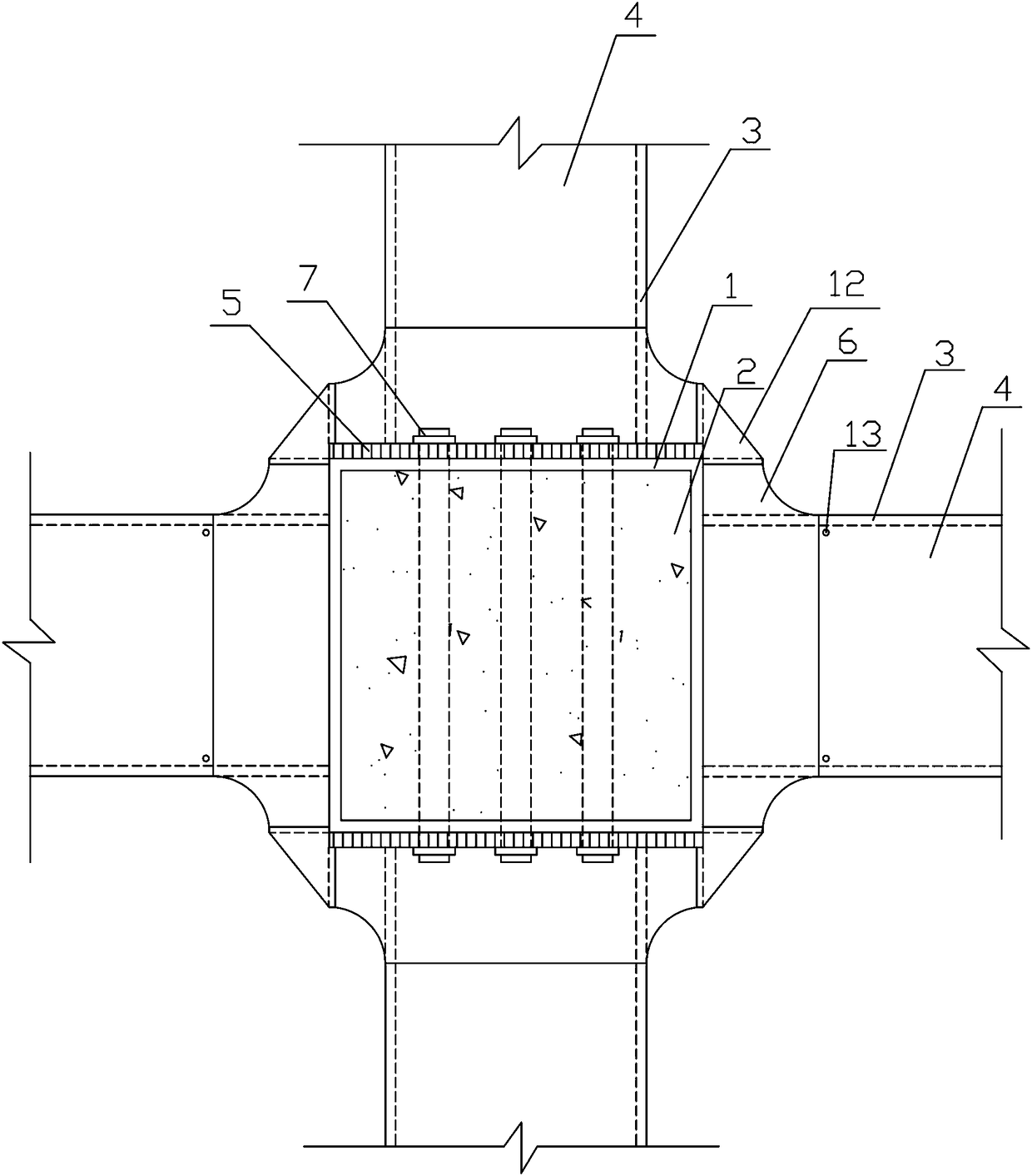

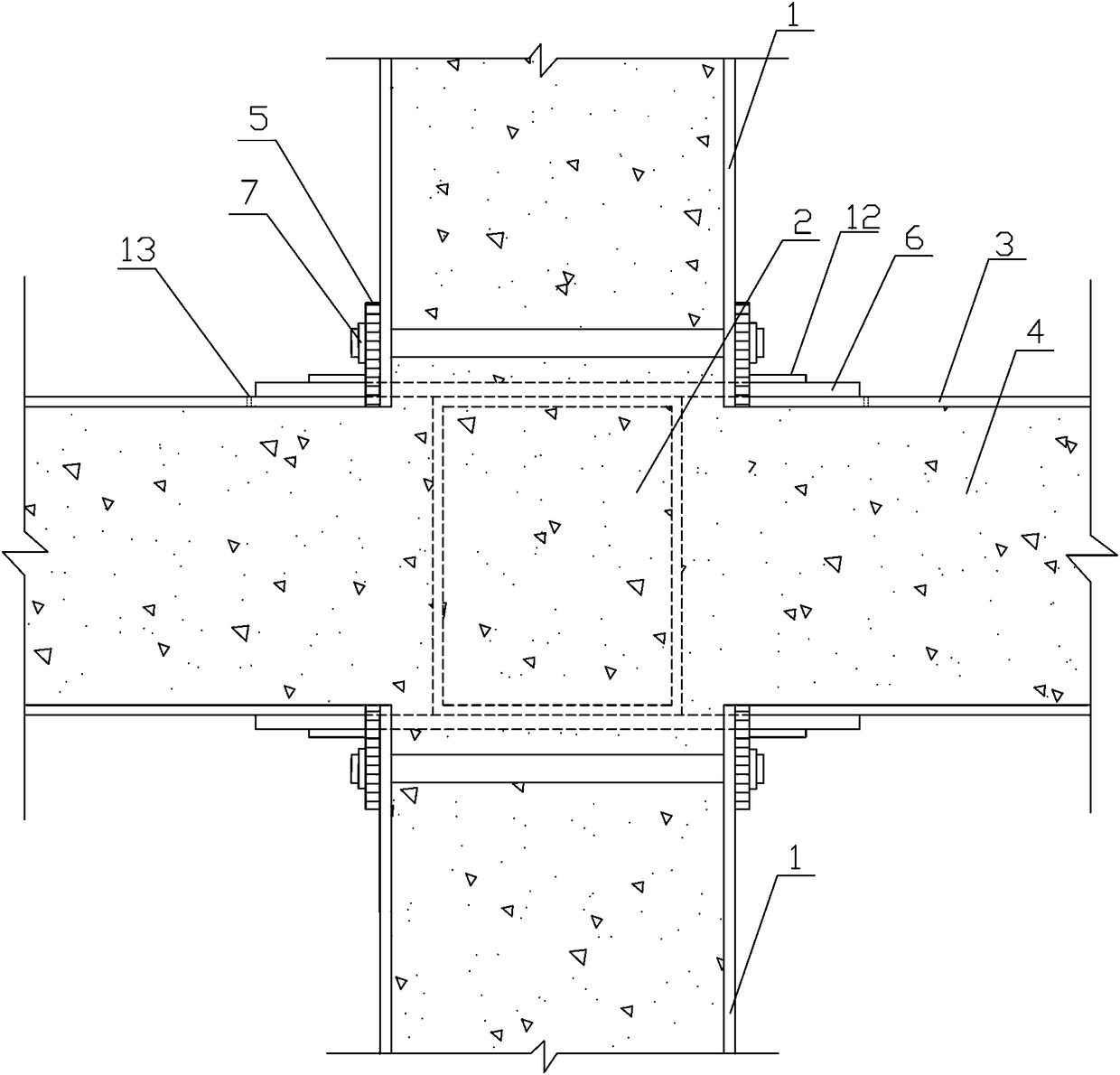

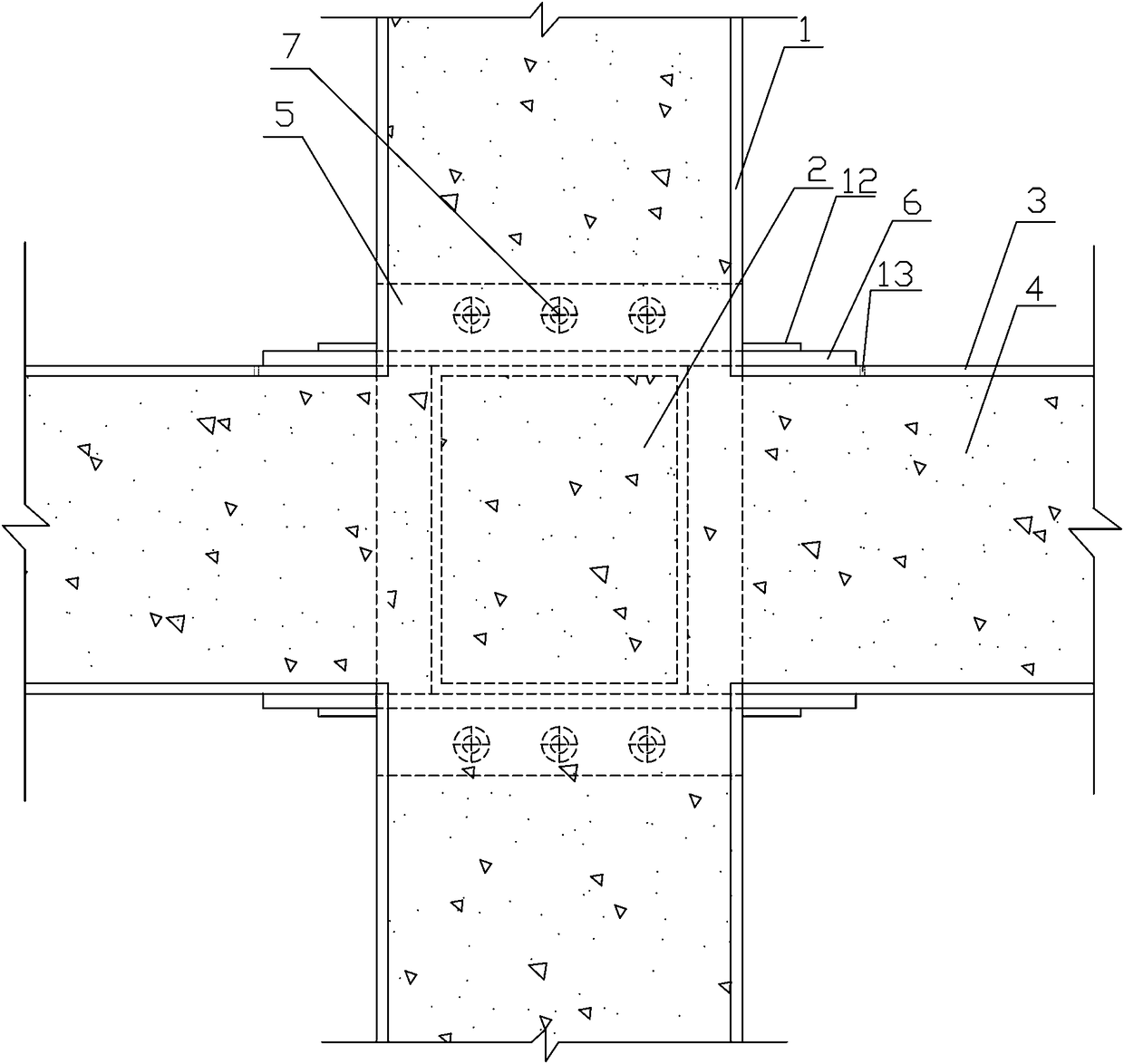

[0036] Below in conjunction with accompanying drawing, the present invention will be further described:

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11As shown, a concrete-filled steel tube column-concrete-filled steel beam joint connection structure includes a concrete-filled steel tube column 8, a concrete-filled steel tube beam 11, a perforated end plate 5, a T-shaped reinforcement plate 6, bolts 7, a triangular piece 12, and a concrete-filled steel tube column 8 It is composed of steel pipe 1 outside the column and concrete 2 inside the column. The concrete-filled steel pipe beam 11 is composed of steel pipe 3 outside the beam and concrete 4 inside the beam. The steel pipe 1 outside the column of the concrete-filled steel pipe column 8 has a rectangular opening around it. The size of the rectangular opening is the same as that of the concrete-filled steel pipe beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com