Method using aluminum formwork to pour floor roof

A technology of aluminum mold and roof plate, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of low transfer efficiency, reduce labor intensity, avoid repeated handling, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

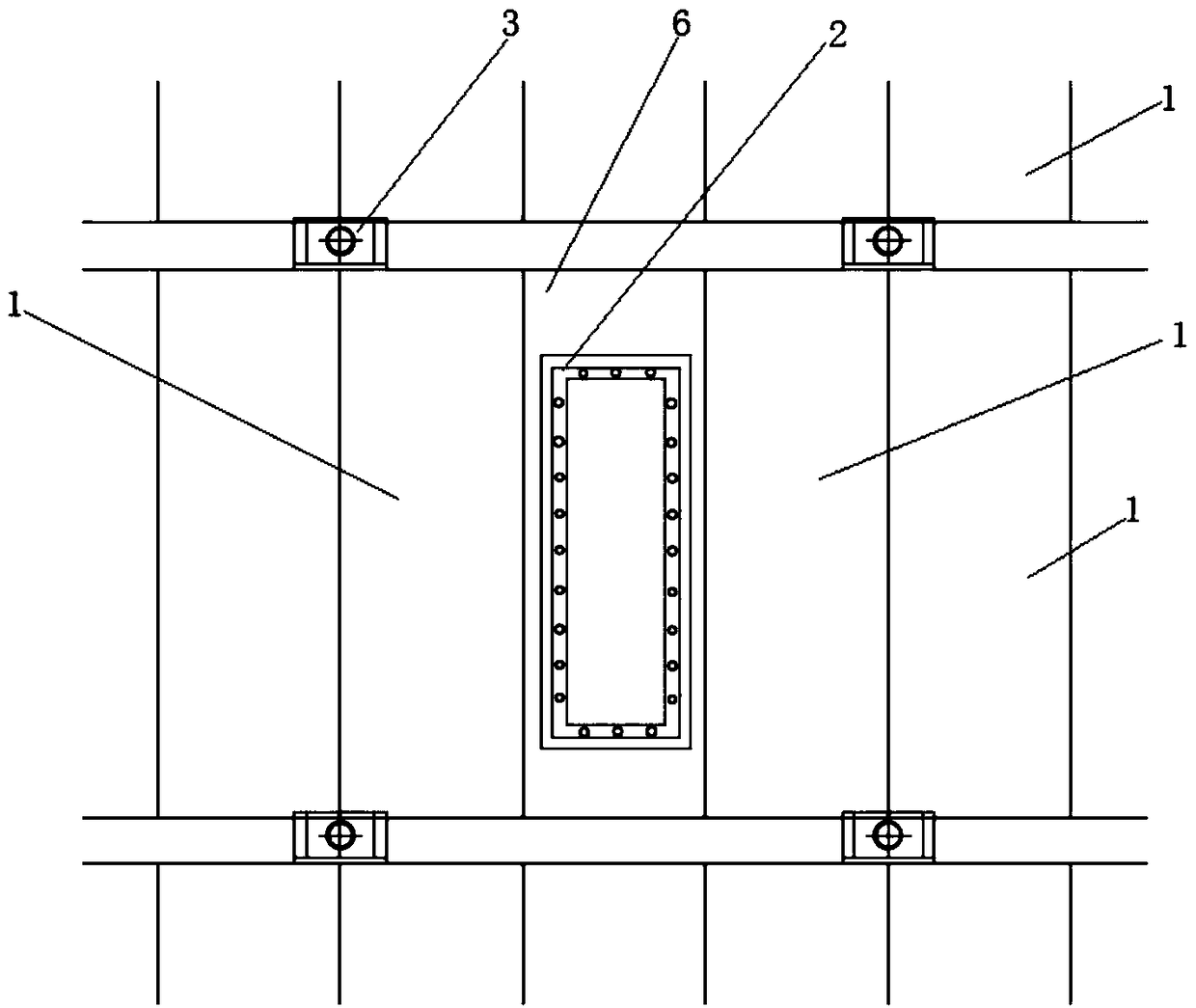

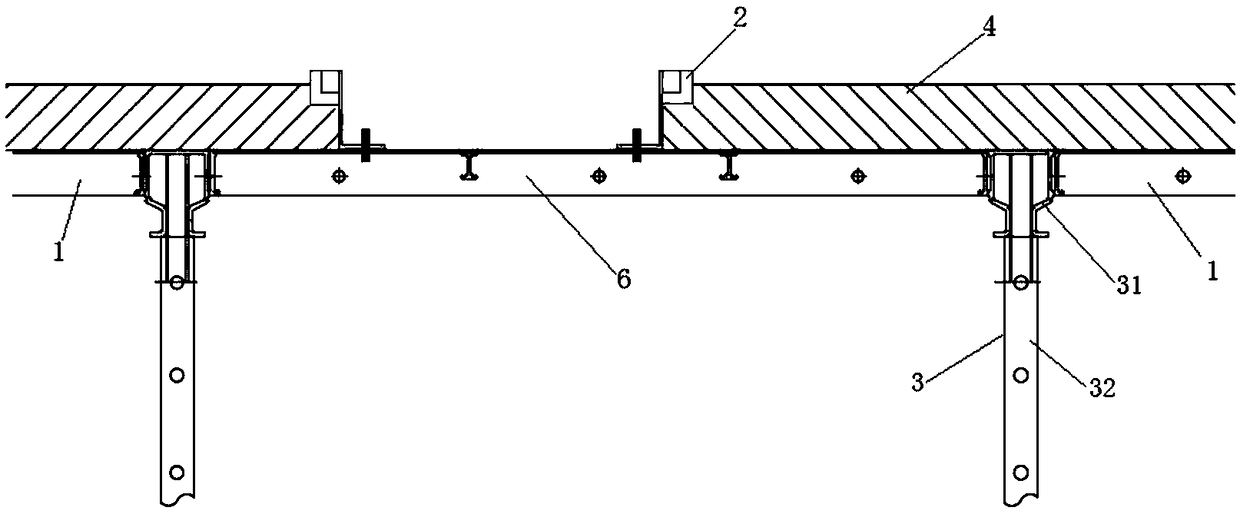

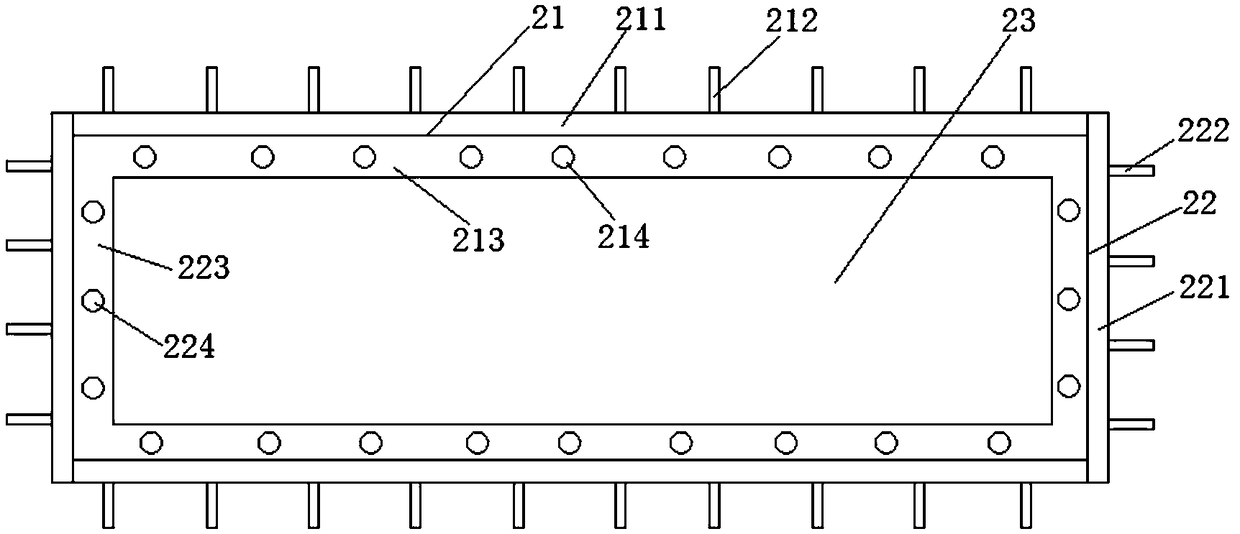

[0036] Such as Figure 1-2 As shown, the aluminum formwork 2 used to make the material transfer hole, when the top floor 4 is poured on the floor foundation that has completed the bottom floor pouring, includes a continuously tiled top formwork 1, and the lower part of the top formwork 1 is supported at even intervals. The supporting device 3, the supporting device includes a supporting top seat 31 on the top and a push rod 32 under the supporting top seat; the top formwork 1 is also provided with an aluminum mold assembly 2, when the top floor 4 is poured , can form material transfer holes on the top floor, used for transferring aluminum formwork and other building materials and small operating tools from the lower floor to the upper floor. Specifically, the aluminum mold assembly 2 includes side plates 21 and end plates 22 , which are connected to each other to form a rectangular cavity 23 . After the top floor 4 is poured, the aluminum formwork 2 and the top formwork 1 can...

Embodiment 2

[0043] Such as Figure 8-10As shown, the difference between this embodiment and embodiment 1 lies in the difference of the aluminum formwork assembly. The aluminum formwork assembly 7 used to make the material transfer hole in this embodiment is welded by aluminum formwork, and the whole is an inverted hollow Quadrangle truss structure; the aluminum template assembly 7 includes a quadrangular pedestal subassembly 71, and a quadrangular prism upper assembly 72 that expands in equal proportions on the upper edge of the quadrangular pedestal subassembly, the quadrangular pedestal upper assembly The lower edge of the body 72 is connected with the upper edge of the lower assembly 71 of the quadrangular platform through a horizontal step portion 73 .

[0044] The outer surface around the aluminum mold assembly 7 is evenly spaced with a number of vertical ribs 74, the bottom of the vertical ribs 74 is located in the middle of the lower assembly 71 of the square platform, and the top ...

Embodiment 3

[0049] Such as Figure 10 , 11 As shown, the supporting device 3 includes a support top seat 31 and a support rod 32 formed under the support top seat 31. The support top seat 31 can use some existing top seats with supporting functions, and in this embodiment in, such as Figure 11-12 As shown, the supporting top seat 31 includes a top seat bottom plate 311, and two parallel and spaced top seat splints 312 arranged longitudinally along the top seat bottom plate 311, the distance between the two top seat splints 312 is not less than two top templates 4 The total thickness of the formwork side plates at the joints of the ends, the support top seat 31 is inserted into the ejector rod 32 through the top seat support column 313 at the bottom, and when the ends of the two top formworks 4 are aligned, the support top seat 31 can be The formwork side panels of the top formwork 4 are sandwiched between two top seat splints 312 to form an effective support.

[0050] The lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com