Anti-backlash cycloid reducer of industrial robot

A cycloid reducer, industrial robot technology, applied in mechanical equipment, transmission parts, gear transmission and other directions, can solve the problems of shortened service life, wear and heat, poor lubrication, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

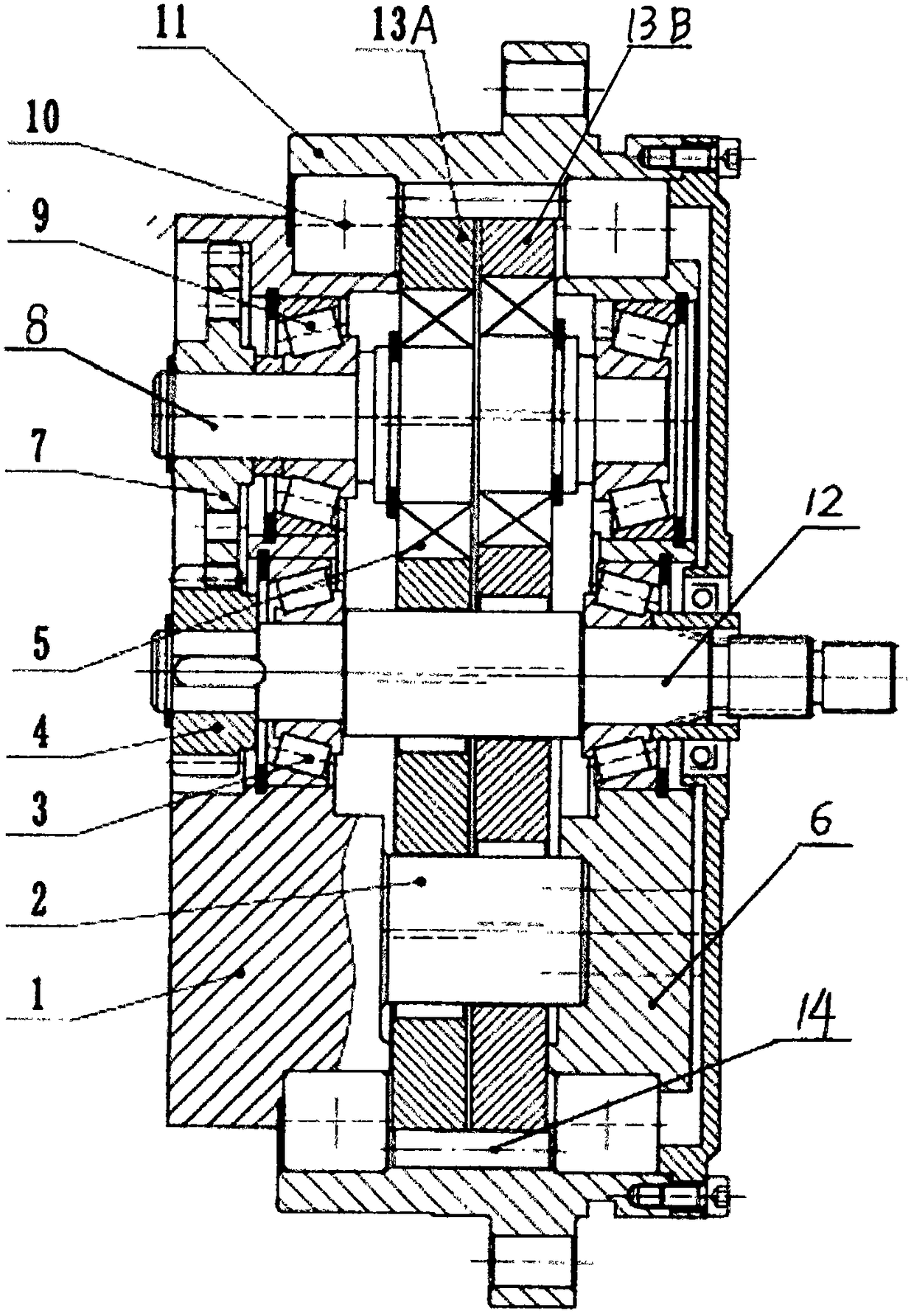

[0032] An anti-backlash cycloidal reducer for an industrial robot, characterized in that it includes a circular shell 11 and a primary deceleration component and a secondary deceleration component placed in the shell. The circular shell is used as the body because the circular shell is lightweight The degree and process performance are the best, among which:

[0033] The primary deceleration part includes an input shaft 12, a sun gear 4 and a planetary gear 7. The planetary gear 7 is connected to the extension end of the eccentric shaft 8 of the secondary deceleration part, so that the speed of the eccentric shaft 8 after the primary deceleration is ≤900rpm, and the eccentric shaft 3 The reason why the rotation speed is lower than 900rpm is that the theoretical profile of the pin wheel (pin gear housing-pin) and the cycloid wheel are not a pair of conjugate curves. In order to make the transmission more stable, the speed of the eccentric shaft 8 has less tooth difference than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com