Boiler exhaust smoke white eliminating and inflow air preheating system

A technology for boiler flue gas and air intake, which is used in emission prevention, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., to achieve the effect of reducing relative humidity, improving overall thermal efficiency, energy consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

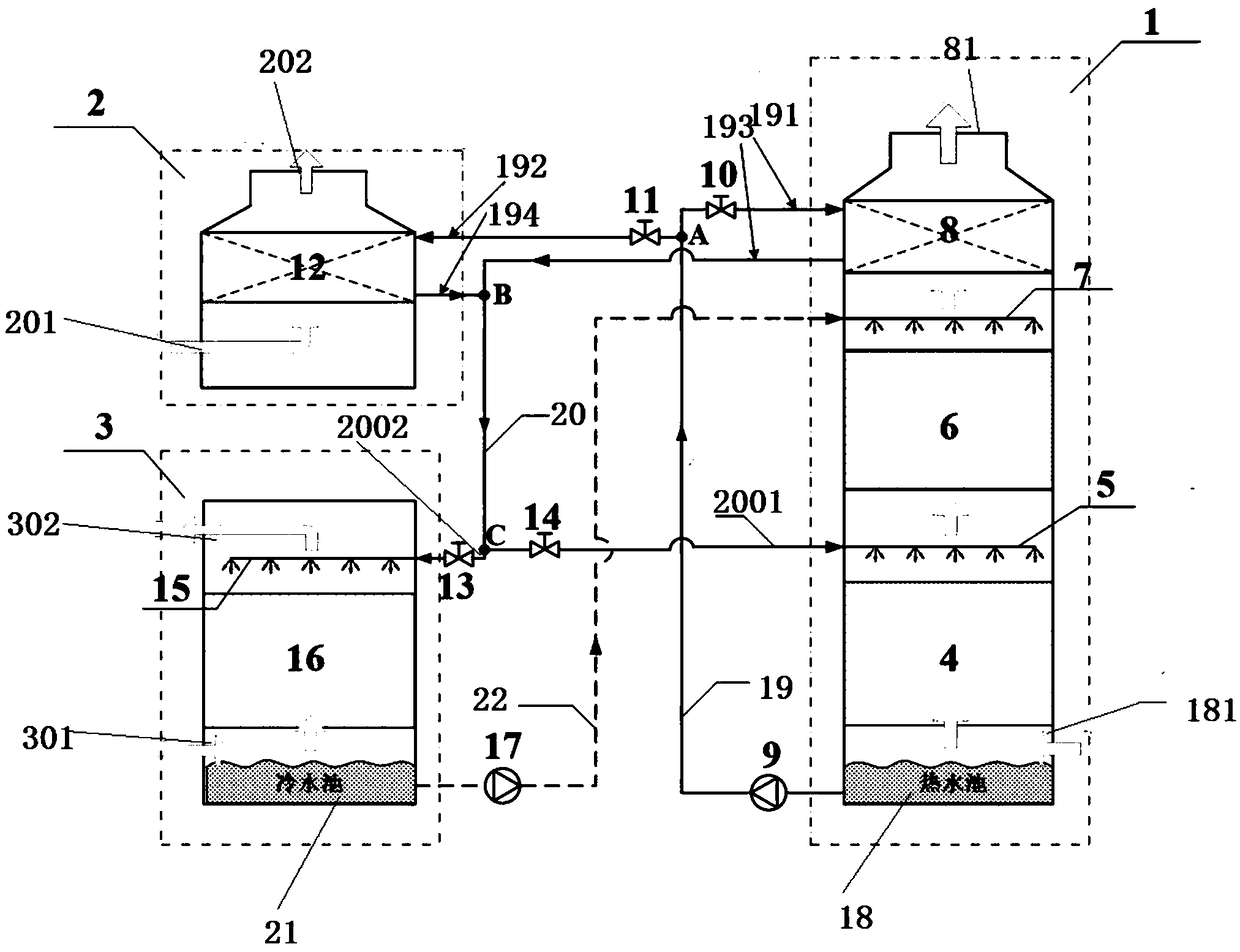

[0020] combined with figure 1 Specific embodiments of the present invention will be further described.

[0021] Such as figure 1 The shown boiler exhaust smoke whitening and air intake preheating system mainly includes a flue gas whitening device 1 , a boiler air intake preheating device 2 and a cooling water preparation device 3 . The flue gas whitening device 1 is provided with a hot water pool 18, a spray tower 1 4, a first hot water shower 5, a spray tower 2 6, a cooling water shower 7 and a first surface cooler from bottom to top. device 8. Among them, the boiler flue gas enters the flue gas whitening device 1 from the bottom inlet, and is initially cooled and dehumidified by the spray tower 14. The first hot water sprayed by the spray tower 4 flows from the top to the bottom of the tower. The residual hot water sprayed by the device 5 and the mixed circulating water composed of the cooling water falling from the upper spray tower No. Moisture is passed to the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com