Power heat pipe inter-column air conditioning system

A technology of inter-column air conditioners and power heat pipes, applied in the field of power heat pipe type inter-column air-conditioning systems, can solve the problems of insufficient driving force and unsatisfactory height difference, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

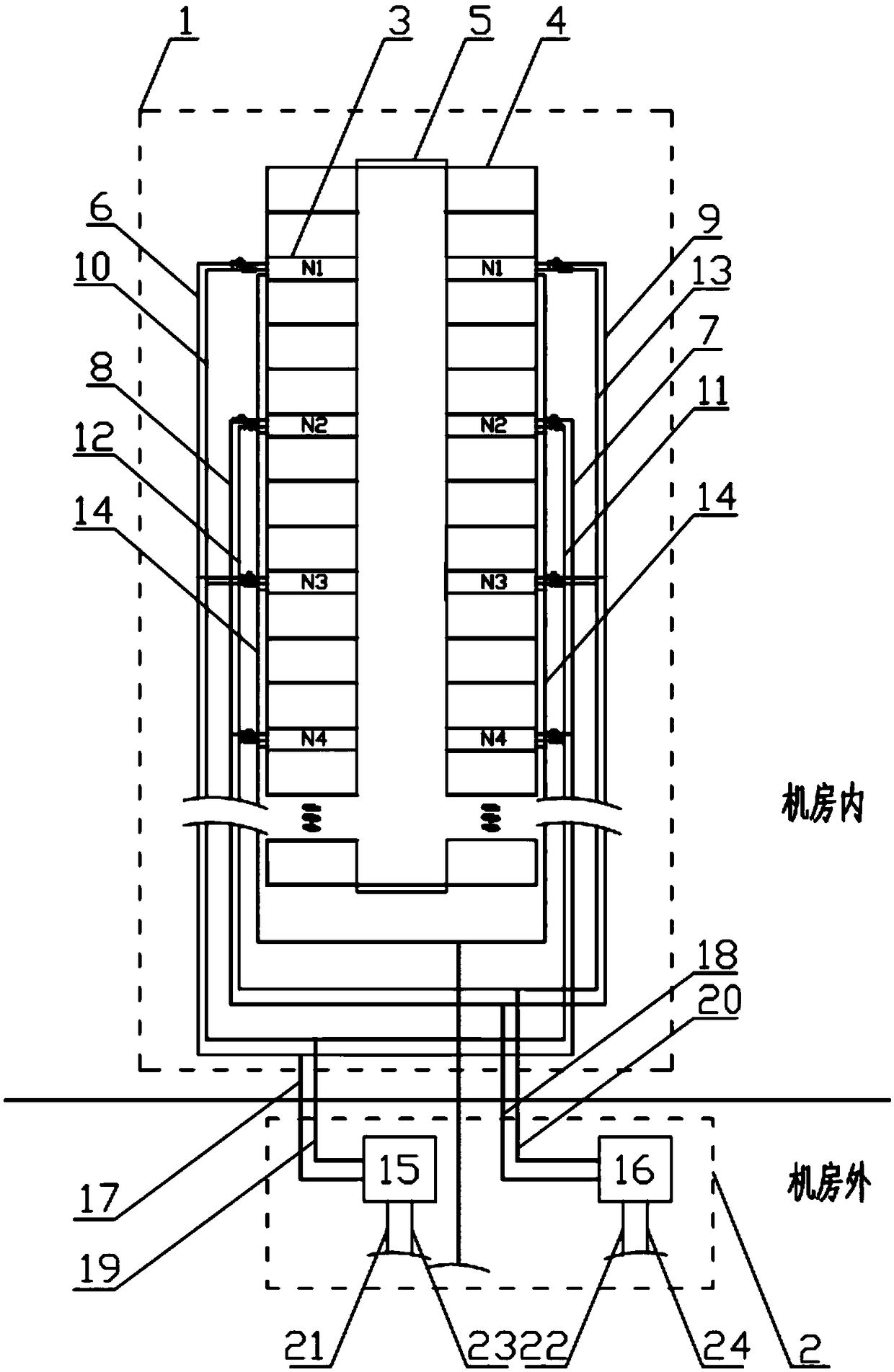

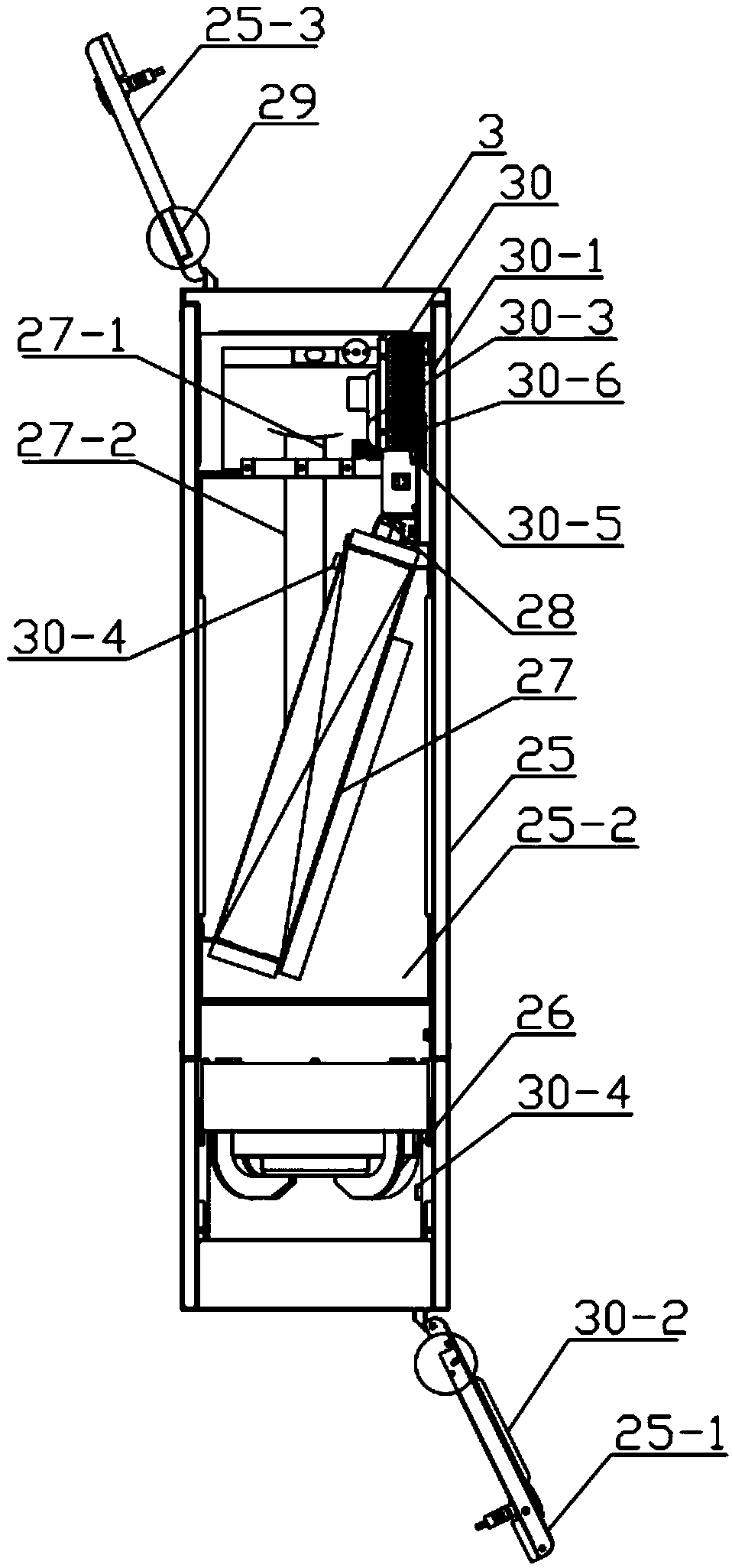

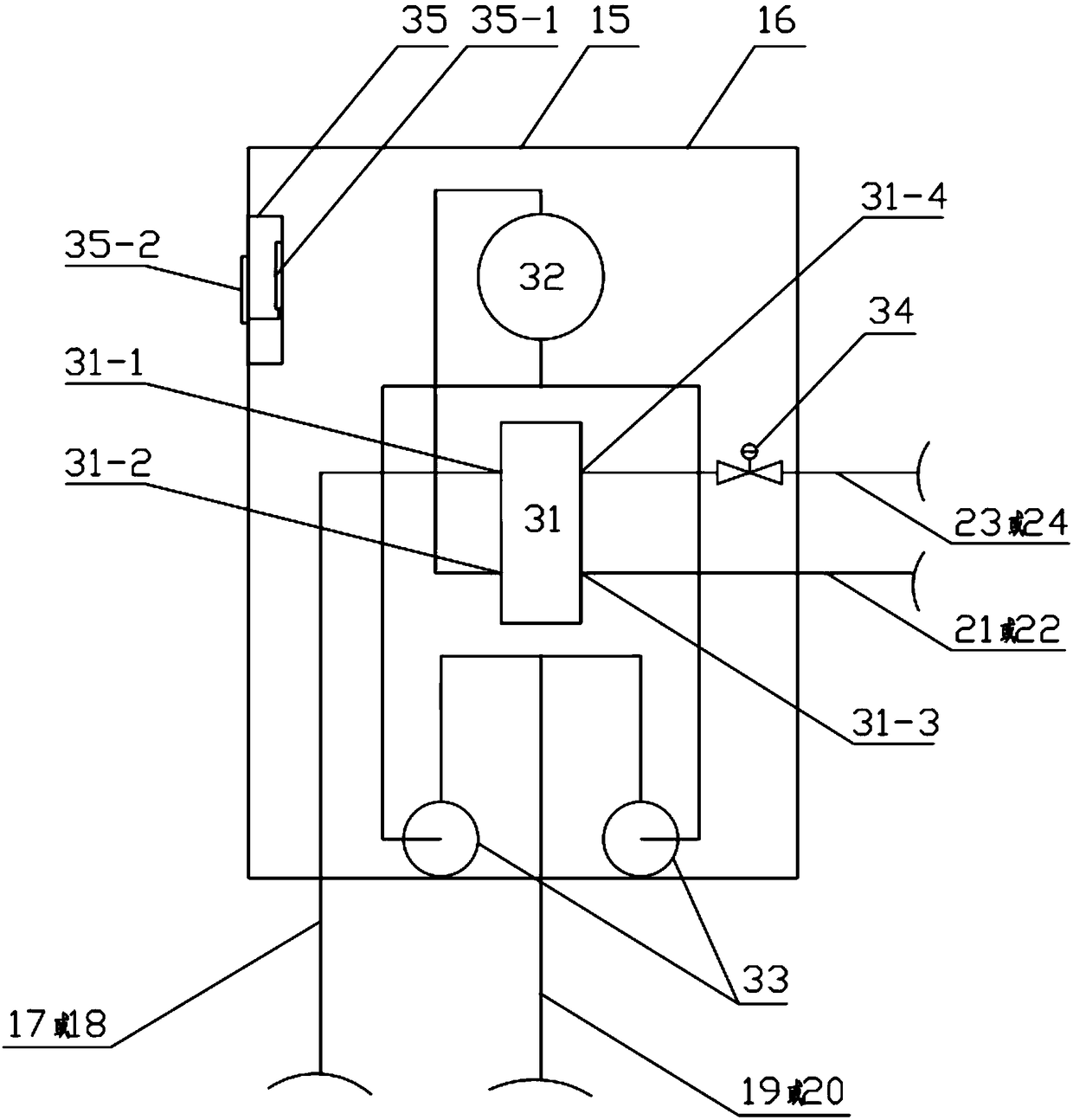

[0037] figure 1 It is a schematic diagram of the power heat pipe type inter-row air-conditioning system of the present invention. As shown in the figure, the power heat pipe type inter-row air-conditioning system of the present invention includes a closed channel module 1 installed in the machine room, and an intermediate heat exchange unit 2 installed outside the machine room, wherein the closed channel module 1 includes two oppositely arranged Several heat pipe inter-column air conditioners 3, several cabinets 4, 1 set of closed channel components 5, air collecting pipe I6, air collecting pipe II7, air collecting pipe III8, air collecting pipe IV9, liquid pipe I10, liquid pipe II11, liquid pipe III12 , liquid distribution pipe IV13, water collection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com