Ceramic-based high-temperature-resistant fluid wall shear stress micro-sensor chip and manufacturing process thereof

A micro-sensor and ceramic-based technology, applied in the field of sensors, can solve problems such as insufficient dynamic performance and sensitivity, difficulty in enduring high-temperature environments, and difficulty in meeting test requirements, so as to improve measurement accuracy, eliminate disturbances, and solve compatibility problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

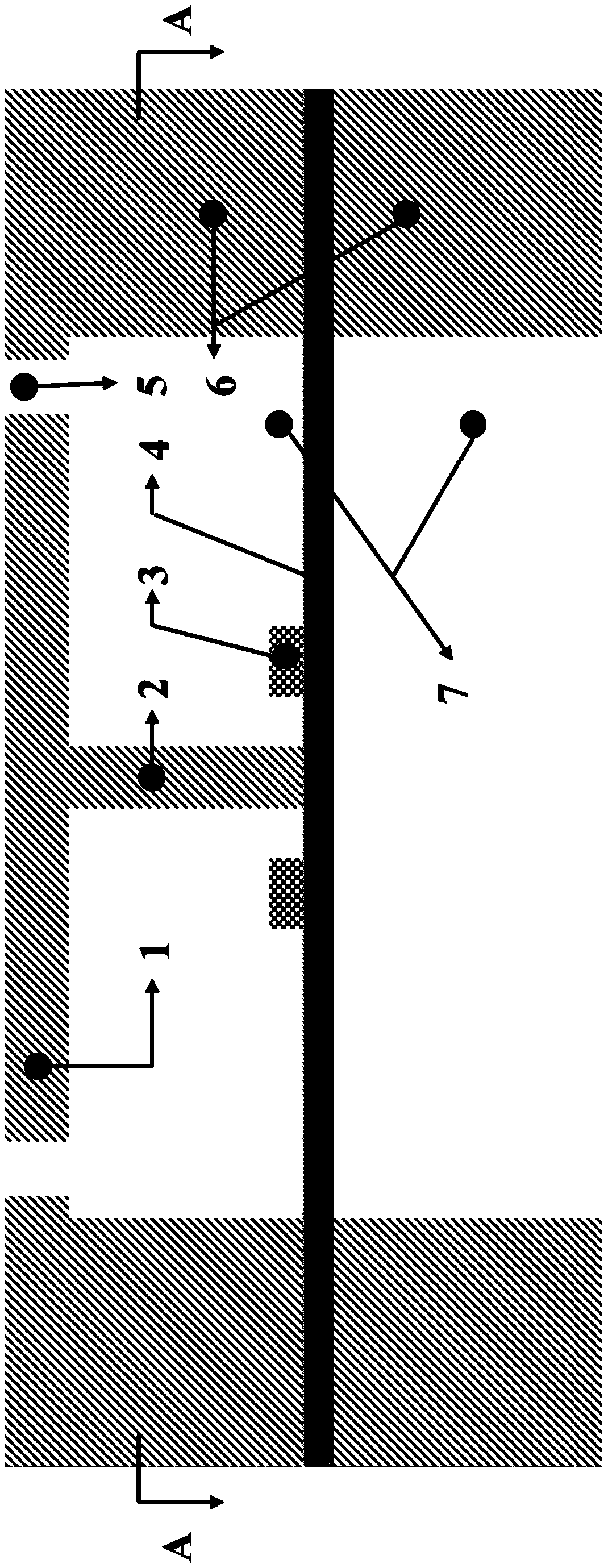

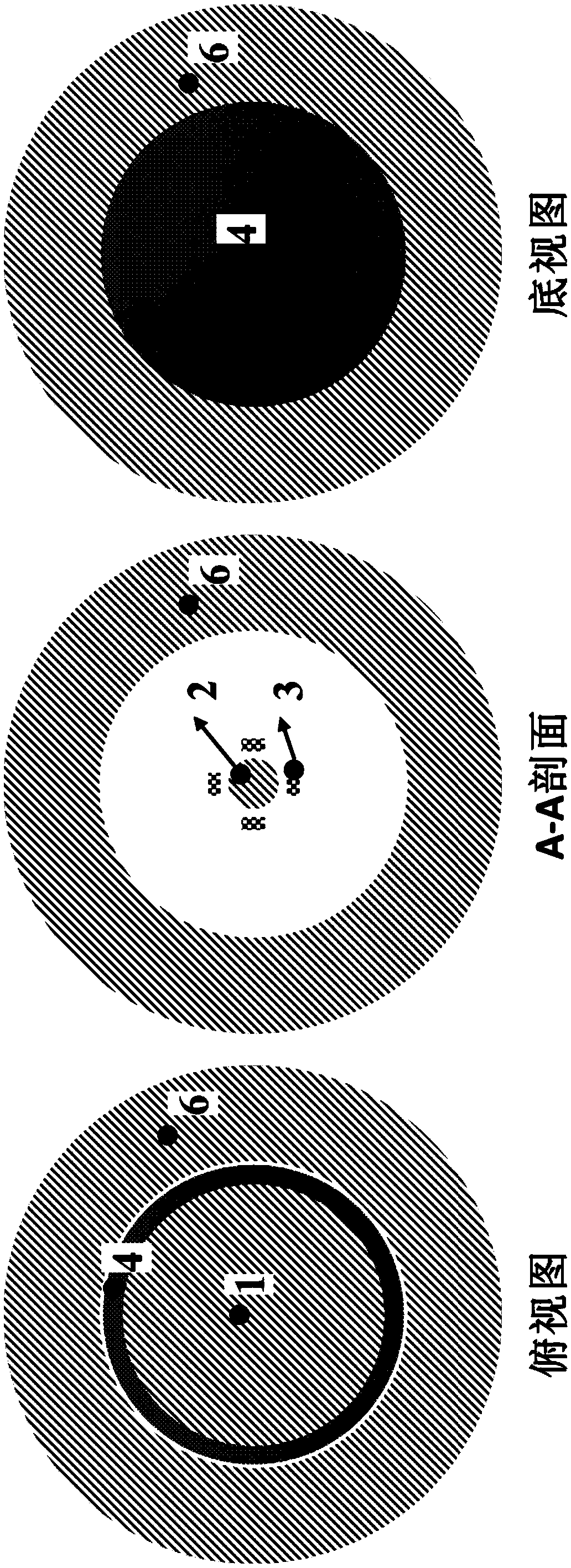

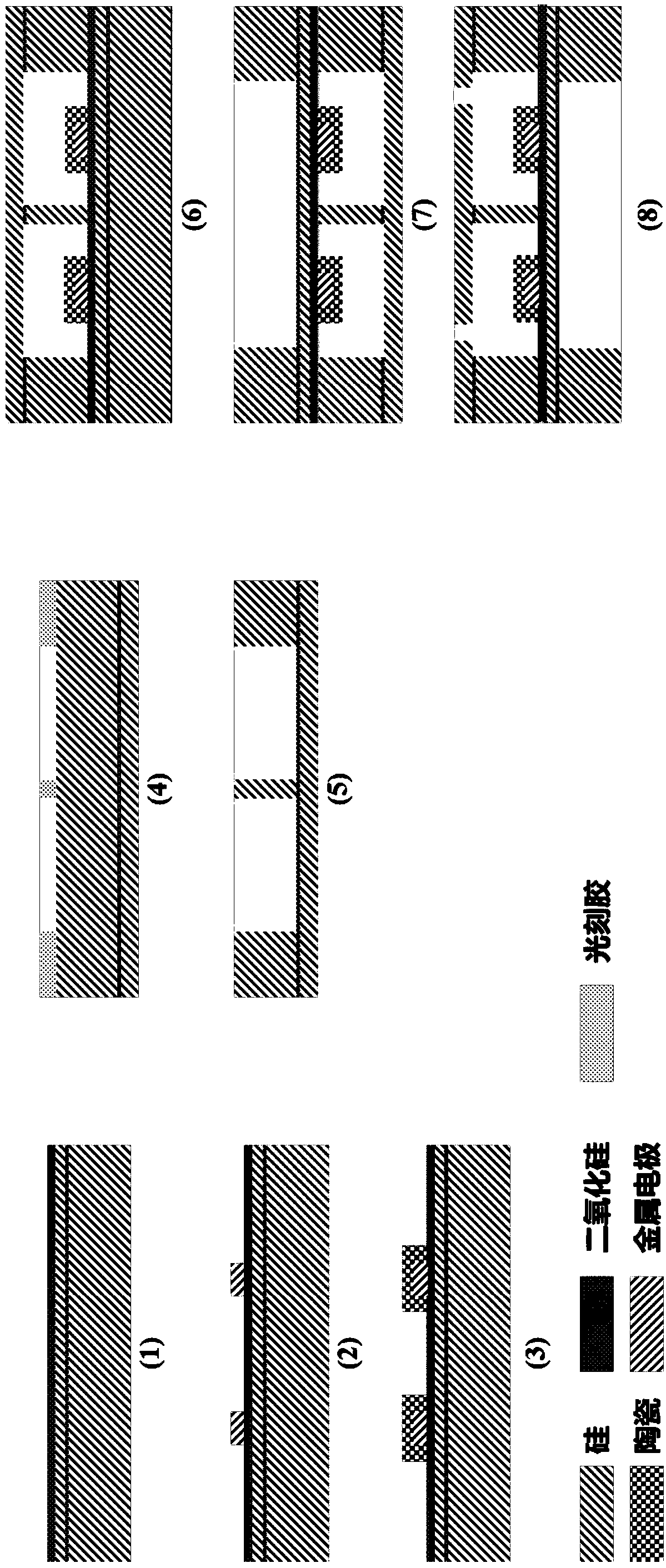

[0030] One of the main features of the ceramic-based high-temperature-resistant fluid wall shear stress microsensor chip in this embodiment is that the sensitive resistor is prepared by polymer-converted ceramic material, which has extremely stable physical and chemical properties, strong oxidation resistance, and can It can withstand high temperature environments exceeding 1000℃, and is currently the highest temperature-resistant micro-sensor for fluid wall shear stress. The second main feature of the ceramic-based high-temperature fluid-resistant wall shear stress microsensor chip is that the ceramic-based varistor of the microsensor is arranged on the elastic diaphragm, reducing the three-dimensional body processing process to a two-dimensional surface processing process, Ensure that the polymer-converted ceramic material molding process is compatible with the MEMS micro-machining process. The third main feature of the ceramic-based high-temperature-resistant fluid wall shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com