Heuristic rule system based crankshaft wearing detection method for industrial robot

A technology of industrial robots and detection methods, which is applied in the testing of machines/structural components, machine gears/transmission mechanisms, and testing of mechanical components. To ensure the accuracy of detection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

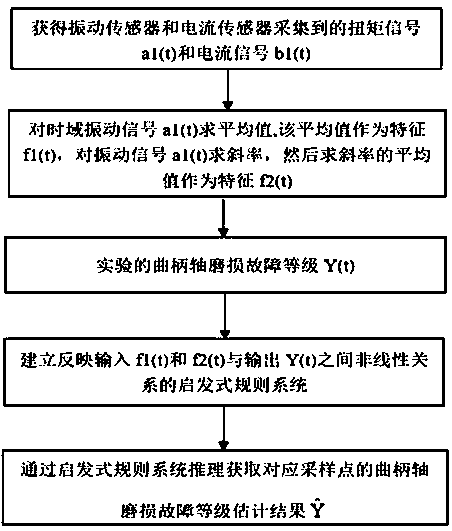

[0042] A kind of heuristic rule system-based industrial robot crankshaft wear detection method, the method comprises the following steps:

[0043] (1) Use the torque signal a1(t) and current signal b1(t) collected by the vibration sensor and current sensor installed on the servo motor of the industrial robot, where the torque unit is mm, the current signal unit is A, a1(t) ∈[-4,2], b1(t)∈[-4,4], the torque signal and the current signal are sampled at the same time every 1 second, a total of T times, 1000≤T<∞, then the sampling time t =1,2,...,T.

[0044] (2) When the current signal is stable, calculate the average value of the time-domain vibration signal a1(t) obtained in step (1), and use the average value as the feature f1(t), calculate the slope of the vibration signal a1(t), and then Find the average of the slopes as the feature f2(t).

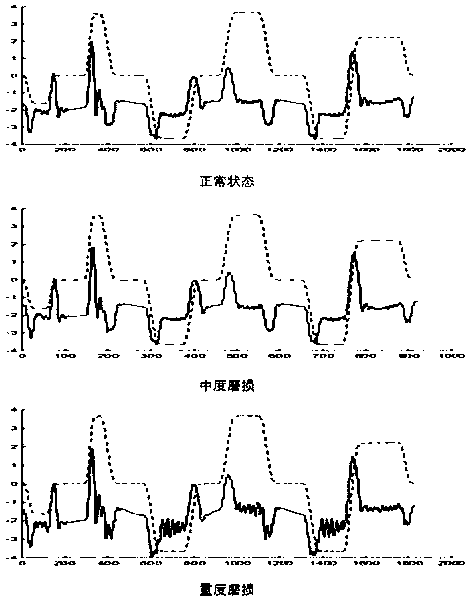

[0045] (3) The output is determined as the crankshaft wear failure level, and the crankshaft is qualitatively divided into three diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com