Rapid testing method for surface tension of molten slag based on heat wire method

A technology of surface tension and test method, applied in the direction of surface/boundary effect, measuring device, material thermal analysis, etc., can solve the problem of long heating time of high temperature furnace, and achieve the effect of fast heating speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1# test slag sample composition:

[0044] Table 1 - 1# experimental slag sample composition (mass%)

[0045] Element

CaO

SiO 2

al 2 o 3

MgO

1#

37.30

38.00

16.80

7.90

[0046] Use chemically pure reagents to prepare 1# slag sample components, melt and homogenize the prepared slag samples at 1400°C for 40 minutes, then water quench the homogenized slag samples, and finally grind the water quenched slag samples through a 200-mesh sieve , to prepare a surface tension test slag sample.

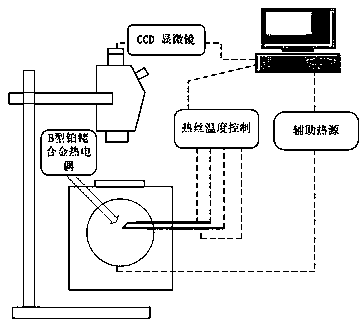

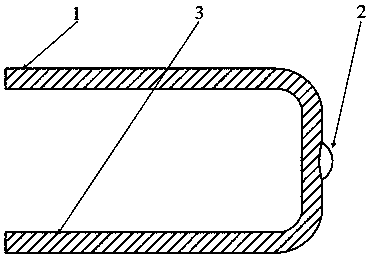

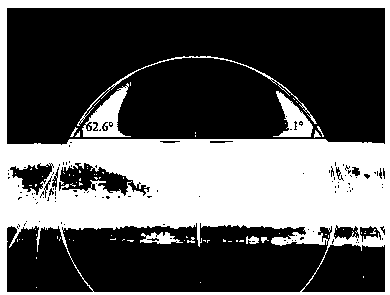

[0047] The schematic diagram of the hot wire method is as figure 1 shown. Operate according to the above-mentioned experimental steps, so that the slag sample is formed on a platinum-rhodium wire thermocouple at 1500°C figure 2 The droplet shape shown in 2. figure 2 Among them, 1 is the positive electrode of the platinum-rhodium wire thermocouple, 2 is the droplet, and 3 is the negative electrode of the platinum-rhodium wire thermo...

Embodiment 2

[0051] 2# test slag sample composition:

[0052]Table 2 - 2# experimental slag sample composition (mass%)

[0053] Element

CaO

SiO 2

al 2 o 3

MgO

2#

42.80

37.10

15.20

4.90

[0054] The preparation method and operation process of the experimental slag sample are the same as in Example 1. The contact angles on both sides of the 2# slag sample were 63.60° and 61.30° respectively, with an average value of 62.45°. The value of the interfacial tension between the 2# slag sample and the platinum-rhodium wire thermocouple at 1600°C is 2116.00mN / m, and the value of the interfacial tension of the platinum-rhodium wire thermocouple is 2370.00mN / m.

[0055] Substituting the above known data into the Young's equation, the surface tension value of the 2# slag sample measured by the hot wire method is 549.13mN / m. According to the surface tension data obtained experimentally in the literature, the surface tension value of 2# slag sample...

Embodiment 3

[0057] 3# test slag sample composition:

[0058] Table 3 Components of 3# experimental slag samples (mass%)

[0059] Element

CaO

SiO 2

al 2 o 3

3#

35.00

60.00

5.00

[0060] The preparation method and operation process of the experimental slag sample are the same as in Example 1. The contact angles on both sides of the 3# slag sample were 56.00° and 54.00° respectively, and the average value was 55.00°. The interfacial tension value between the 3# slag sample and the platinum-rhodium wire thermocouple at 1500°C is 2116.00mN / m, and the interfacial tension value of the platinum-rhodium wire thermocouple is 2370.00mN / m.

[0061] Substituting the above known data into the Young's equation, the surface tension value of the 3# slag sample measured by the hot wire method is 432.11mN / m. According to the surface tension data obtained experimentally in the literature, the surface tension value of the 3# slag sample is 418.70mN / m (see "Sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension value | aaaaa | aaaaa |

| Surface tension value | aaaaa | aaaaa |

| Surface tension value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com