Asymmetric four-branch fractional slot stack winding connection method

A connection method and asymmetric technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the problem of poor technical and economic indicators of power station systems, unreasonable motor performance and structure, and unreasonable motors. performance and other issues, to achieve the effect of facilitating installation and binding, improving safety and reliability, and facilitating manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear.

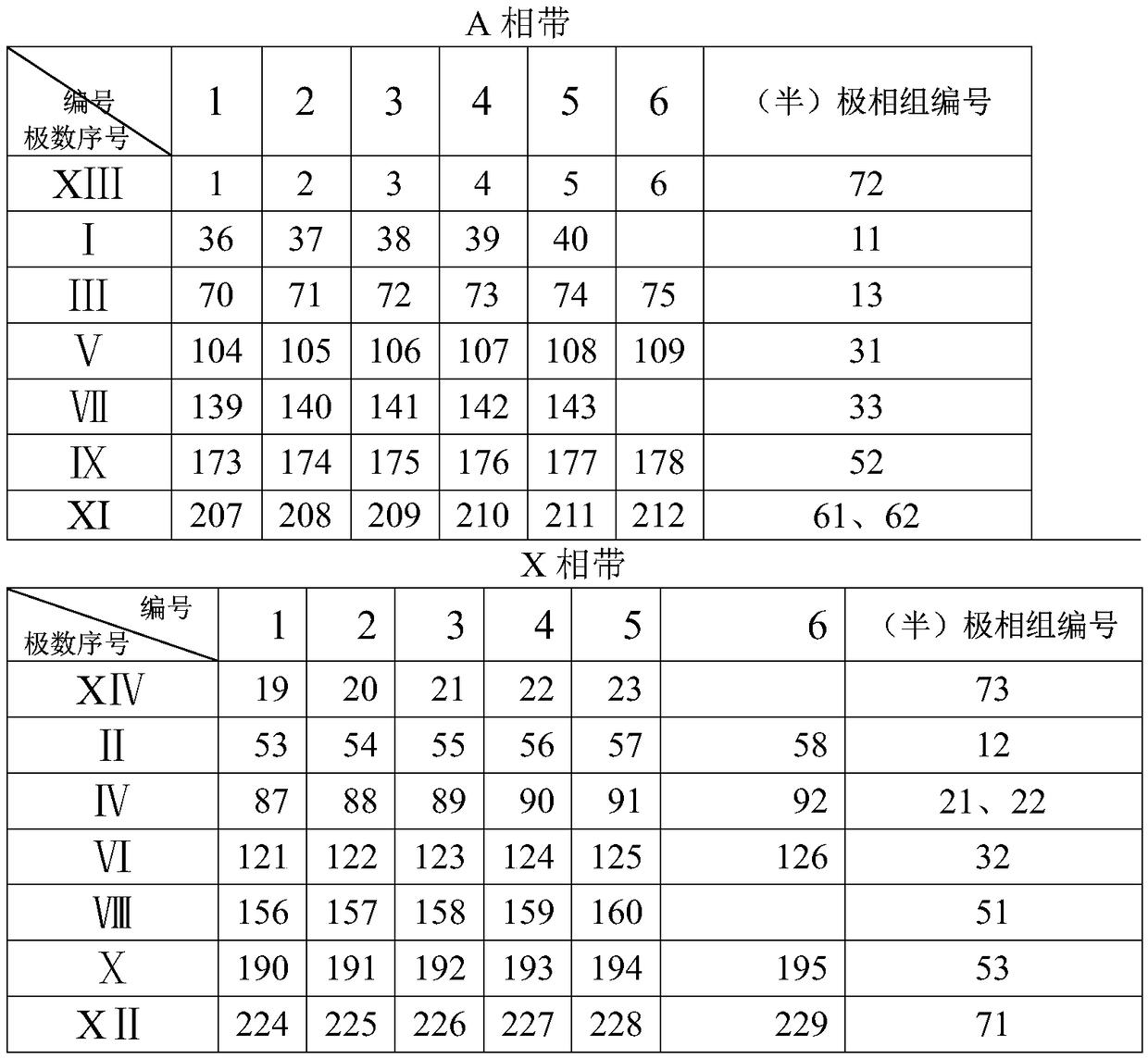

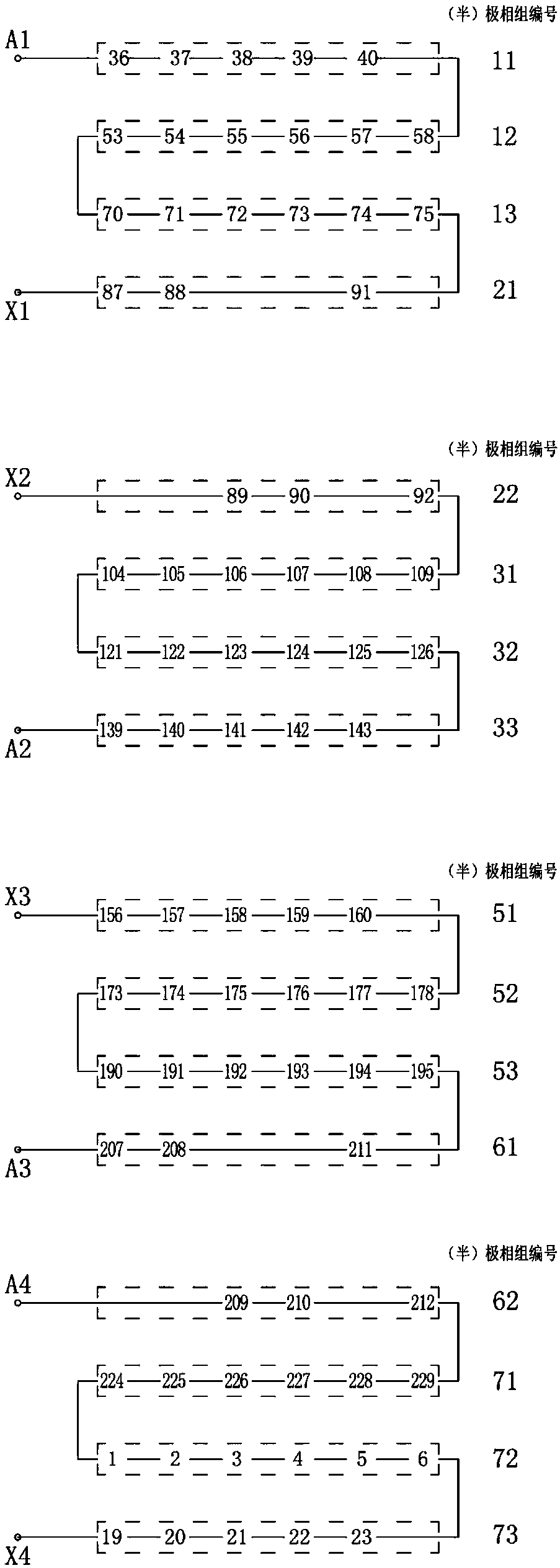

[0020] The invention provides a connection method for asymmetrical four-branch split-slot stacked windings: a double-layer winding composed of pole phase groups and semi-pole phase groups connected in series according to the principle of potential addition, and the pole phase groups and semi-pole phase groups are composed of coils According to the principle of potential addition, the coil is formed in series in sequence; the coil is composed of the upper layer wire rod and the lower layer wire rod through the end connection, and the connection adjustment of the coil is carried out at the end of the outlet side; the coil pitch is selected according to the weakening of the harmonic, and is Equal-pitch coils; each phase winding is composed of four parallel branches, each branch winding is asymmetrically distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com