Flexible printed circuit board and magnetic field coil manufacturing method based on the printed circuit board

A flexible printing, magnetic field coil technology, applied in the direction of multi-layer circuit manufacturing, printed circuit components, including printed electrical components, etc. problems, to achieve the effect of convenient parameter modification, good consistency, improved efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

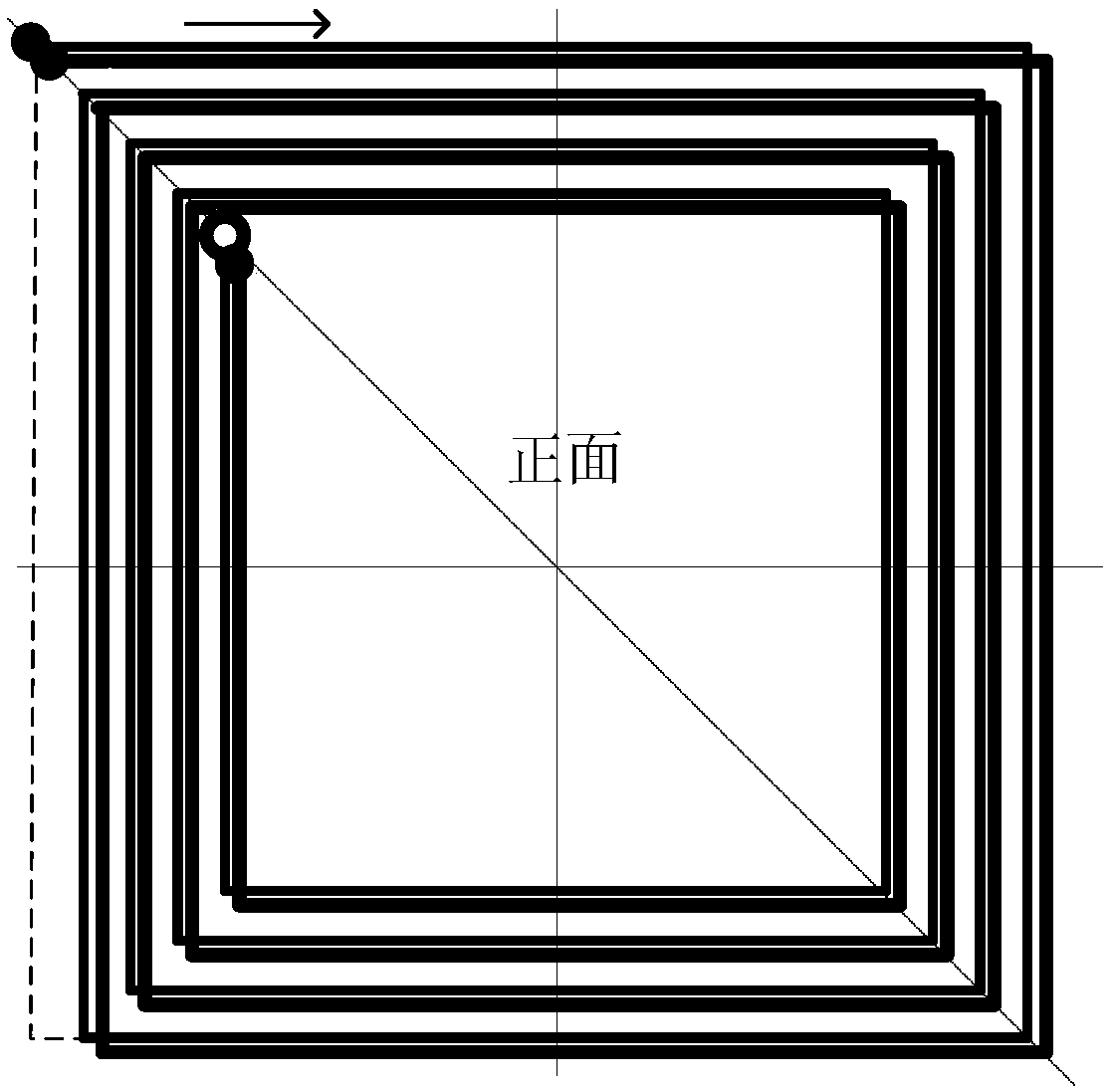

Image

Examples

Embodiment

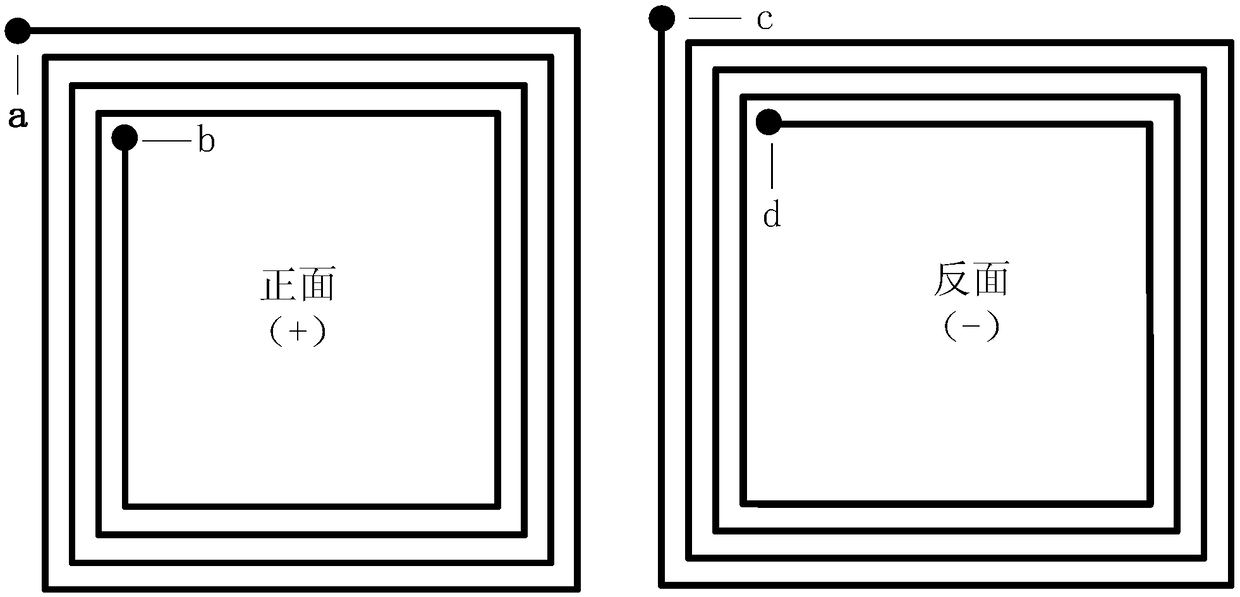

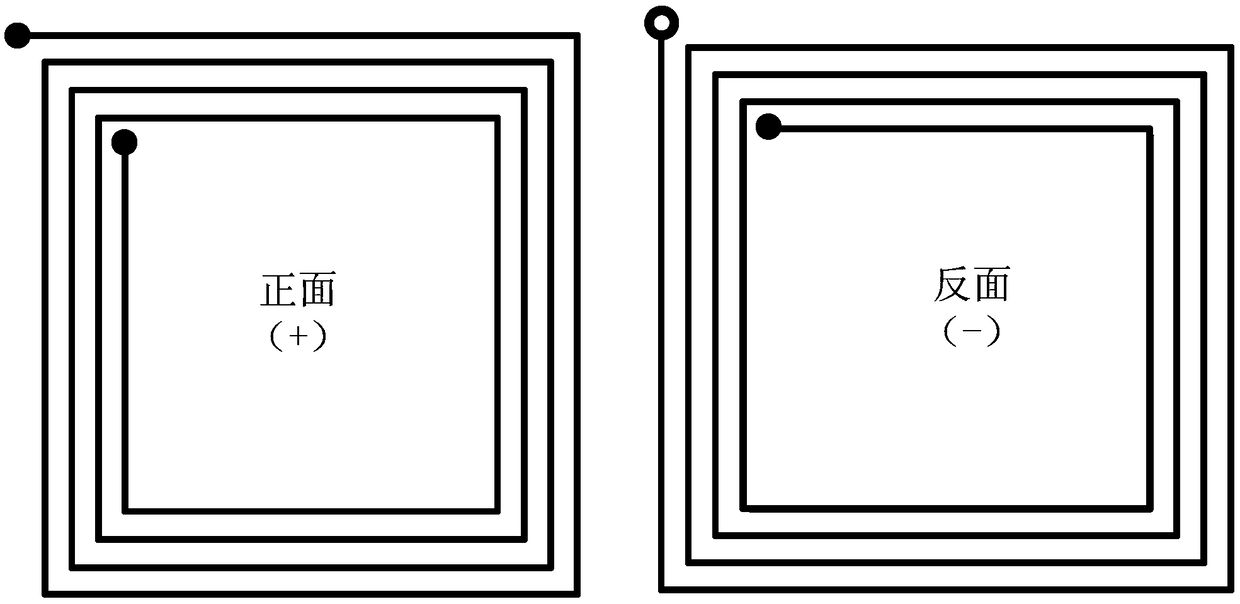

[0069] 1. Continuous parallel embodiment. Parallel connection means that the current flows in (outflow) from pad a and pad c, and flows out (inflow) from pad b and pad d. Then all adjacent pads a and pad c must be conductive, and all phases Adjacent pad b and pad d must be conductive, and all four pads are required to be conductive pads. Therefore, it is determined that the A version must be arranged in order to realize the parallel connection. For example, 5 parallel structure, a sequence of placement is:

[0070] A+: A- / A+: A- / A+: A- / A+: A- / A+: A-.

[0071] 2. Continuous series embodiment. The series connection requires that only one corresponding pad is connected between the lower coil on the upper circuit board and the upper coil on the lower circuit board, and the other corresponding pad is insulated from each other. In this embodiment, a certain pad insulation of the upper coil of the circuit board below is adopted, such as a 5-series structure, and a placement sequence i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com