Application method of vegetable cake combined production line

A production line and combined technology, which is applied in application, food coating, and the function of food ingredients, etc., can solve the problems of low product output and quality, messy equipment, inconsistent size, etc., and achieve small space occupation and market Good prospects and less artificial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

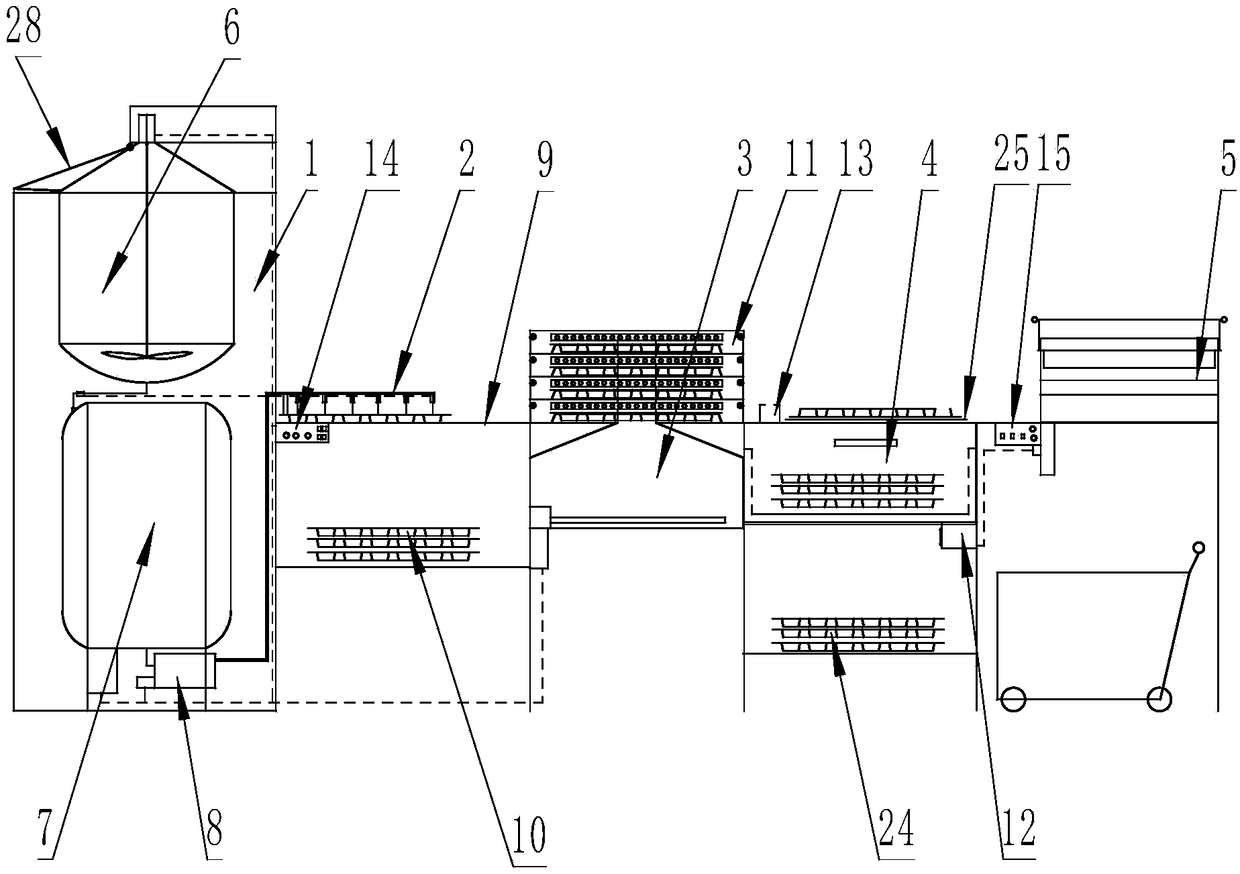

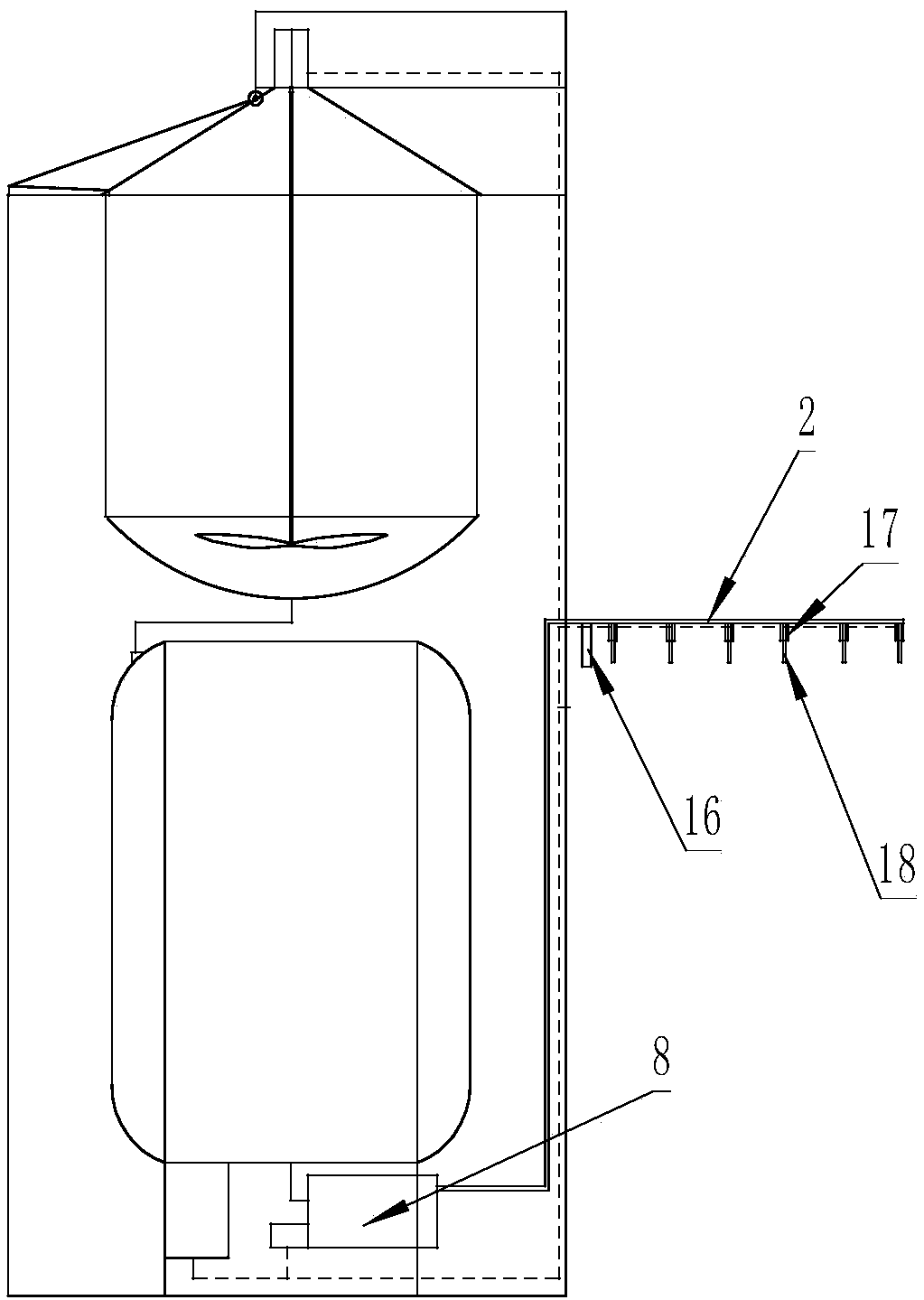

[0029] The front end of the vegetable and vegetarian cake combined production line is provided with a stuffing processing device 1, a chopping machine 6 is set above the stuffing processing device 1, a feeding cover 28 is set above the chopping machine 6, and a discharge port is set at the bottom of the chopping machine 6; A tumbler 7 is arranged below the chopping machine 6, a side of the top of the tumbler 7 is provided with a feed inlet, and a filling delivery pipeline is set between the feed inlet and the discharge opening at the bottom of the chopping machine 6, and the filling delivery pipeline An electromagnetic valve is provided; the lower part of the tumbler 7 is provided with a stuffing delivery port, and a delivery pump 8 is arranged on one side of the filling delivery port, and a filling delivery port is set between the stuffing delivery port and the filling inlet of the delivery pump 8, and the delivery pump 8. The upper end of the pipeline of the stuffing outlet i...

Embodiment 2

[0038] After completing the rolling and kneading processing of the vegetable vegetarian cake ingredients and fillings, through two manual processing, the filling processing and filling console 14 is manually controlled to start the steamer 3 and the delivery pump 8 at the same time, the steamer 3 is heated, and the delivery pump 8 is used to transport vegetables Vegetarian cake ingredients and fillings; by manually placing the first layer of steamer 11 on the steam port 20 above the steamer 3, the two sides of the filling platform 9 are operating stations, and there are two operating personnel on the operating stations on both sides. Manually take out the vegetarian cake mold 10 and place it under the mold filling device 2. When the vegetarian cake mold 10 is manually pushed forward, the inner edge of the vegetarian cake mold 10 pushes the touch switch 16. The touch switch 16 starts the filling solenoid valve 17, and the filling solenoid The valve 17 is opened and the vegetable...

Embodiment 3

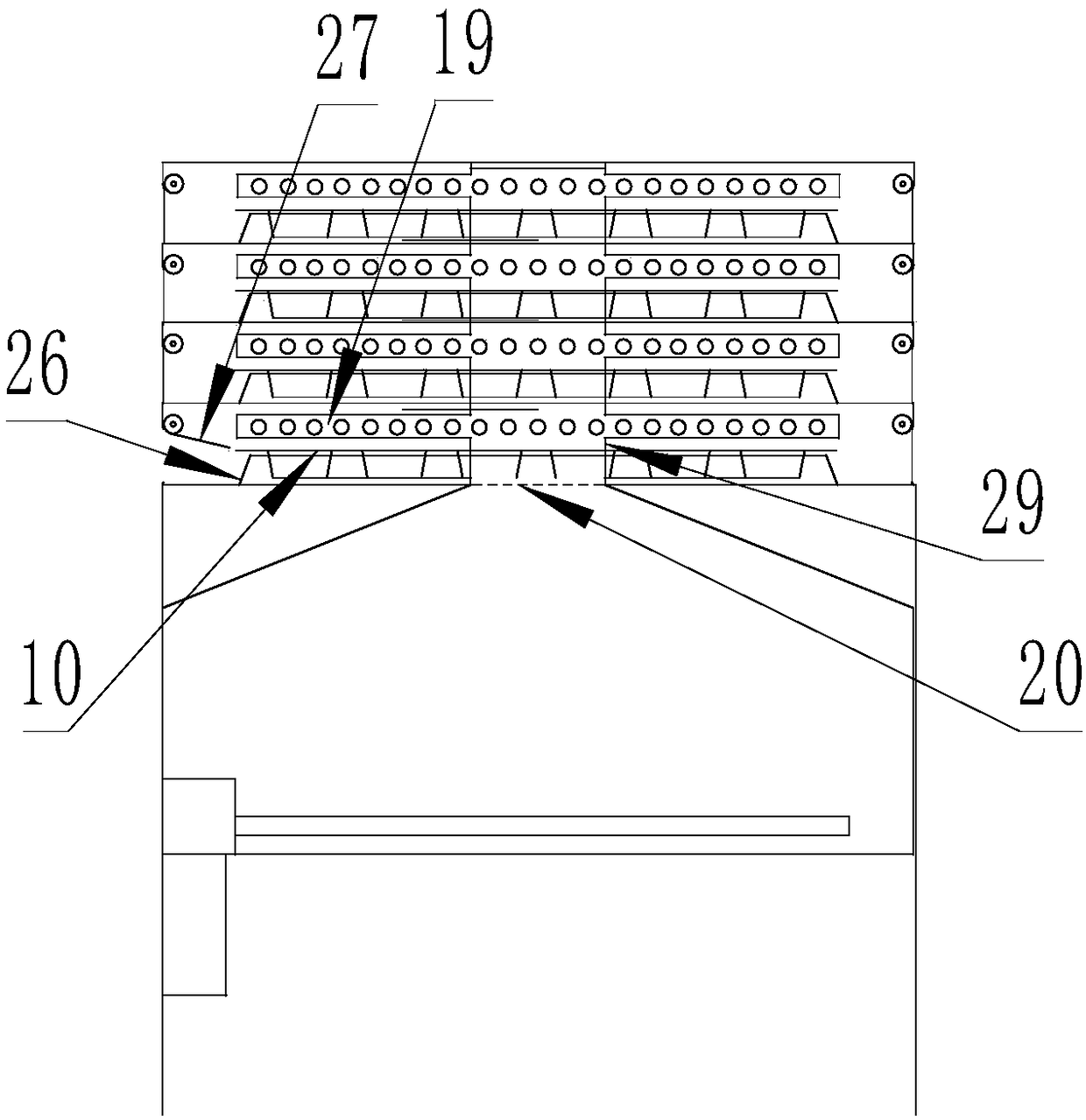

[0040] After the filling of vegetable vegetarian cake ingredients and fillings in the first vegetarian cake mold 10 mold cavity is completed, the vegetarian cake mold 10 is manually pushed to the left and enters on the mold slide frame 26 in the first layer of cage drawer steamer 11 through the airtight door 27, When cooking is required in the drawer steamer 11, the steam channel valve 23 in the first layer of the drawer steamer 11 is closed, and the steam in the steamer 3 enters the steamer steamer through the upper steam port 20, steam channel 29, and steam outlet 19. In the box 11; when using the second layer of the steamer 11 on the cage, by manually lifting the first layer of the steamer 11, the second layer of the steamer 11 is pushed into the lower end of the first layer of the steamer 11, so that the second The steam channel 29 of the first-layer steamer 11 is the same as that of the first-layer steamer 11. The second vegetarian cake mold 10 that has been filled is push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com