Using method of selenium-enriched fish sausage automatic control combined production line

A selenium-enriched fish sausage and production line technology, applied in application, food forming, food science, etc., can solve the problems of difficult management of environmental sanitation, messy equipment, affecting normal production, etc., to reduce the number of labor and compact structure Orderly and takes up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

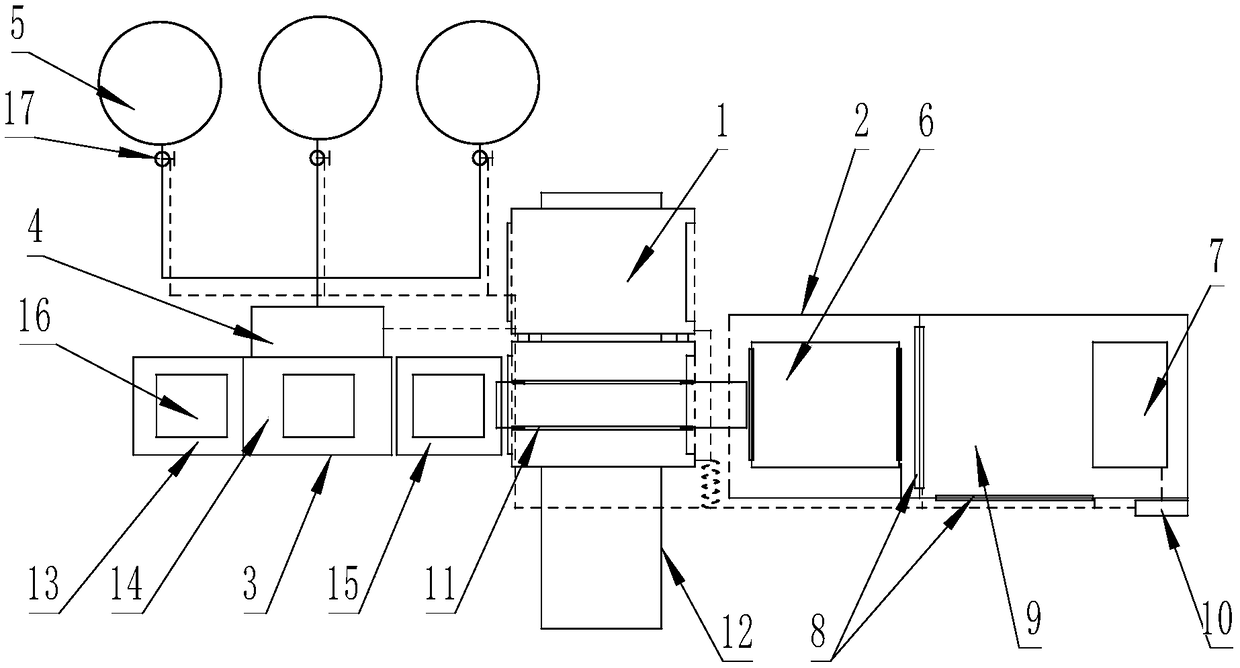

[0020] The selenium-enriched fish sausage automatic control combination production line is placed horizontally on the same straight line, and the loading platform 3, the sterilization cabinet 15, the parallel combination steaming cabinet 1, the aseptic packaging platform 2, and the rear side of the table top of the loading platform 3 are set. KAP automatic filling and binding machine 4, at least two refrigerated ingredient tanks 5 are arranged on one side of the KAP automatic filling and binding machine 4, and a feeding pipeline is arranged between the refrigerated ingredient tanks 5 and the feed inlet of the KAP automatic filling and binding machine 4, and the refrigerated ingredient tanks Electromagnetic feeding valves 17 are respectively provided at the feeding pipeline ports of 5; an empty tray rack 13 is arranged at one end of the loading platform 3, and a cage grate plate 16 is arranged on the empty tray rack 13, and a cage grate for receiving and packing meat sausage is a...

Embodiment 2

[0027] After the refrigerated ingredient filling 5 is filled with stuffing, the electromagnetic feeding valve 17, the KAP automatic filling and binding machine 4, the parallel combination steaming cabinet 1, the sterilizing and drying cabinet 6, the air curtain 8, and the sealing are controlled through the PLC console 10 according to programming. The bag packaging machine 7 starts at the same time, and the parallel combined steam cabinet 1, sterilizing and drying cabinet 6, and bag sealing and packaging machine 7 are preheated. 9 Turnover openings are reserved at the front end for airflow closure.

Embodiment 3

[0029] The PLC console 10 controls the opening of the electromagnetic feeding valve 17 of one of the three refrigerated ingredient fillings 5, and closes its electromagnetic feeding valve 17 after the filling in one of the refrigerating ingredient fillings 5 is used up; After the electromagnetic feeding valve 17 of the ingredient filling 5, the PLC console 10 controls another of the three refrigerated ingredient filling 5 to open the electromagnetic feeding valve 17 of the refrigerating ingredient filling 5;

[0030] After the electromagnetic feeding valve 17 of a refrigerated ingredient filling 5 is opened, the stuffing outputted by the electromagnetic feeding valve 17 enters the KAP automatic filling and binding machine 4 for enema for packaging. Manually put in the cage grate pan 16 and put it full, and put the semi-finished selenium-enriched fish sausage in the cage grate pan 16 and put it full, and then manually push it into the sterilization cabinet 15 for sterilization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com