Water-resistant high-temperature-resistant methane oxidation catalyst and preparation method thereof

A methane oxidation and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low methane catalytic activity and catalyst instability , to achieve high removal efficiency, good stability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

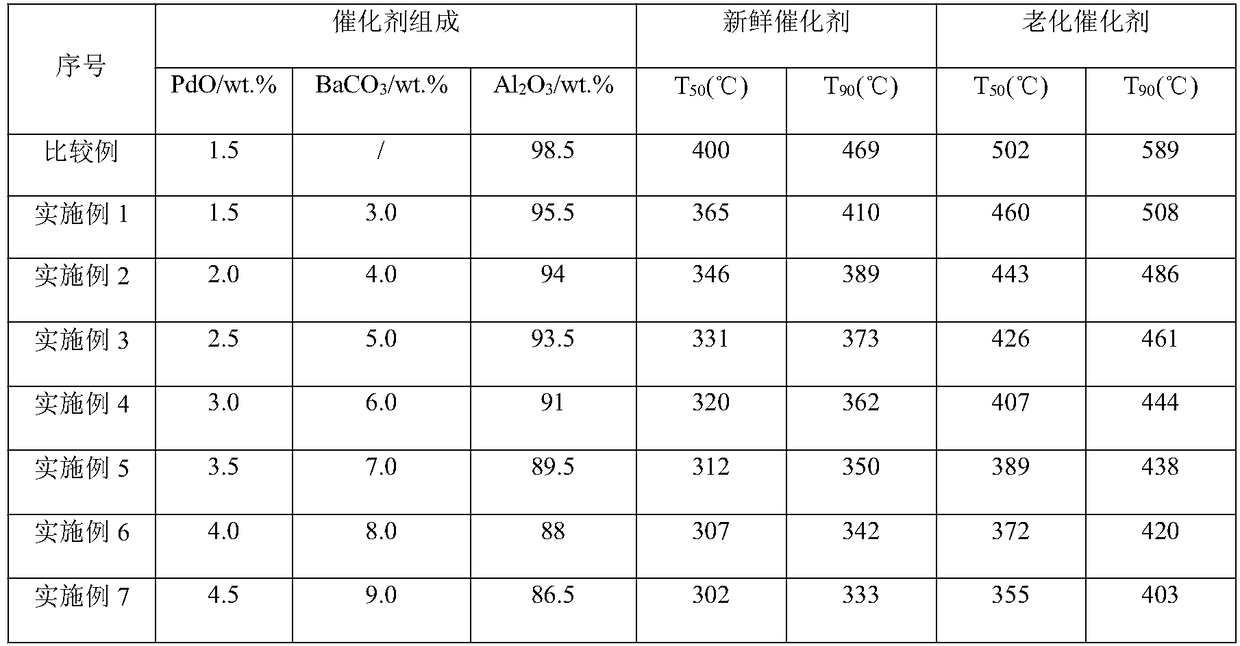

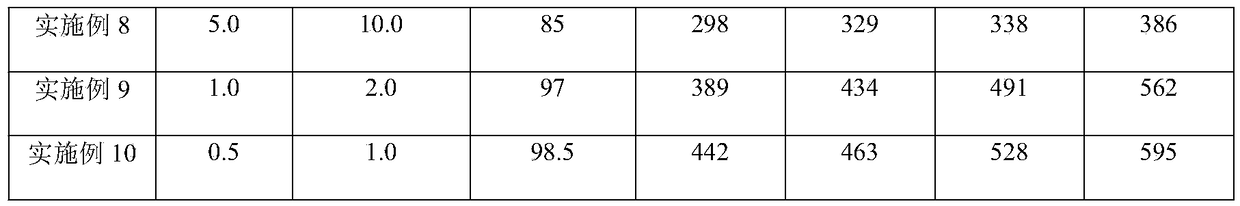

Embodiment 1

[0024] (1) Weigh 0.78g Ba(CH 3 COO) 2 Prepared as Ba precursor aqueous solution, added to 19.1gAl 2 o 3 (The specific surface area is 195m 2 / g, the pore volume is 0.78ml / g), let it stand at room temperature for 2h, put it in an oven to dry overnight at 120°C, and roast it in a muffle furnace at 600°C for 6h;

[0025](2) Pd(NO 3 ) 2 Move the aqueous solution to the carrier obtained in (1), ultrasonicate for 30 minutes at 80% power in an ultrasonic cleaner, evaporate to dryness in a water bath at 90°C, put it in an oven, dry overnight at 100°C, and bake in a muffle furnace at 600°C for 4 hours .

Embodiment 2

[0027] (1) Weigh 1.03g Ba(CH 3 COO) 2 Prepared as Ba precursor aqueous solution, added to 18.8gAl 2 o 3 (The specific surface area is 195m 2 / g, the pore volume is 0.78ml / g), let it stand at room temperature for 2h, put it in an oven to dry overnight at 120°C, and roast it in a muffle furnace at 600°C for 6h;

[0028] (2) Pd(NO 3 ) 2 Move the aqueous solution to the carrier obtained in (1), ultrasonicate for 30 minutes at 80% power in an ultrasonic cleaner, evaporate to dryness in a water bath at 90°C, put it in an oven, dry overnight at 100°C, and bake in a muffle furnace at 600°C for 4 hours .

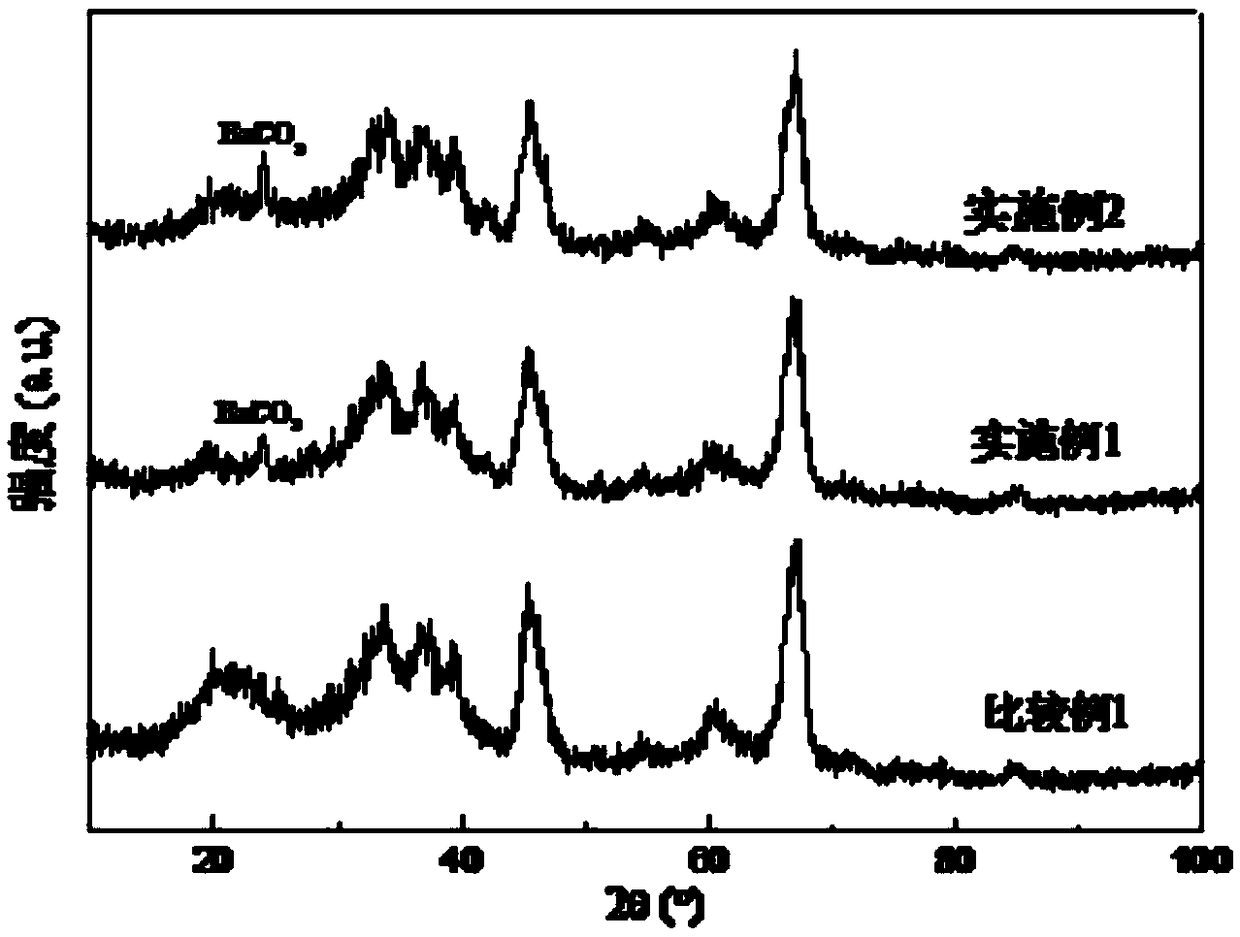

[0029] The phase structure characterization of comparative example, embodiment 1, embodiment 2.

[0030] from figure 1 It can be seen that the PdO / BaCO synthesized by the preparation method provided by the present invention 3 / Al 2 o 3 The phase structure of the Ba species in the catalyst is BaCO 3 .

Embodiment 3

[0032] (1) Weigh 1.30g Ba(CH 3 COO) 2 Prepared as Ba precursor aqueous solution, added to 18.7gAl 2 o 3 (The specific surface area is 195m 2 / g, the pore volume is 0.78ml / g), let it stand at room temperature for 2h, put it in an oven to dry overnight at 120°C, and roast it in a muffle furnace at 600°C for 6h;

[0033] (2) Pd(NO 3 ) 2 Move the aqueous solution to the carrier obtained in (1), ultrasonicate for 30 minutes at 80% power in an ultrasonic cleaner, evaporate to dryness in a water bath at 90°C, put it in an oven, dry overnight at 100°C, and bake in a muffle furnace at 600°C for 4 hours .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com