Pulse current assisted hollow splitting micro-forming die and method for titanium alloy micro-gear

A technology of pulse current and titanium alloy, which is applied in the direction of metal extrusion die, etc., can solve the problems of difficulty in forming titanium alloy micro-gear or gear shaft structure, and low service life of the mold, so as to improve micro-forming performance, high forming efficiency, Effect of deformation resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

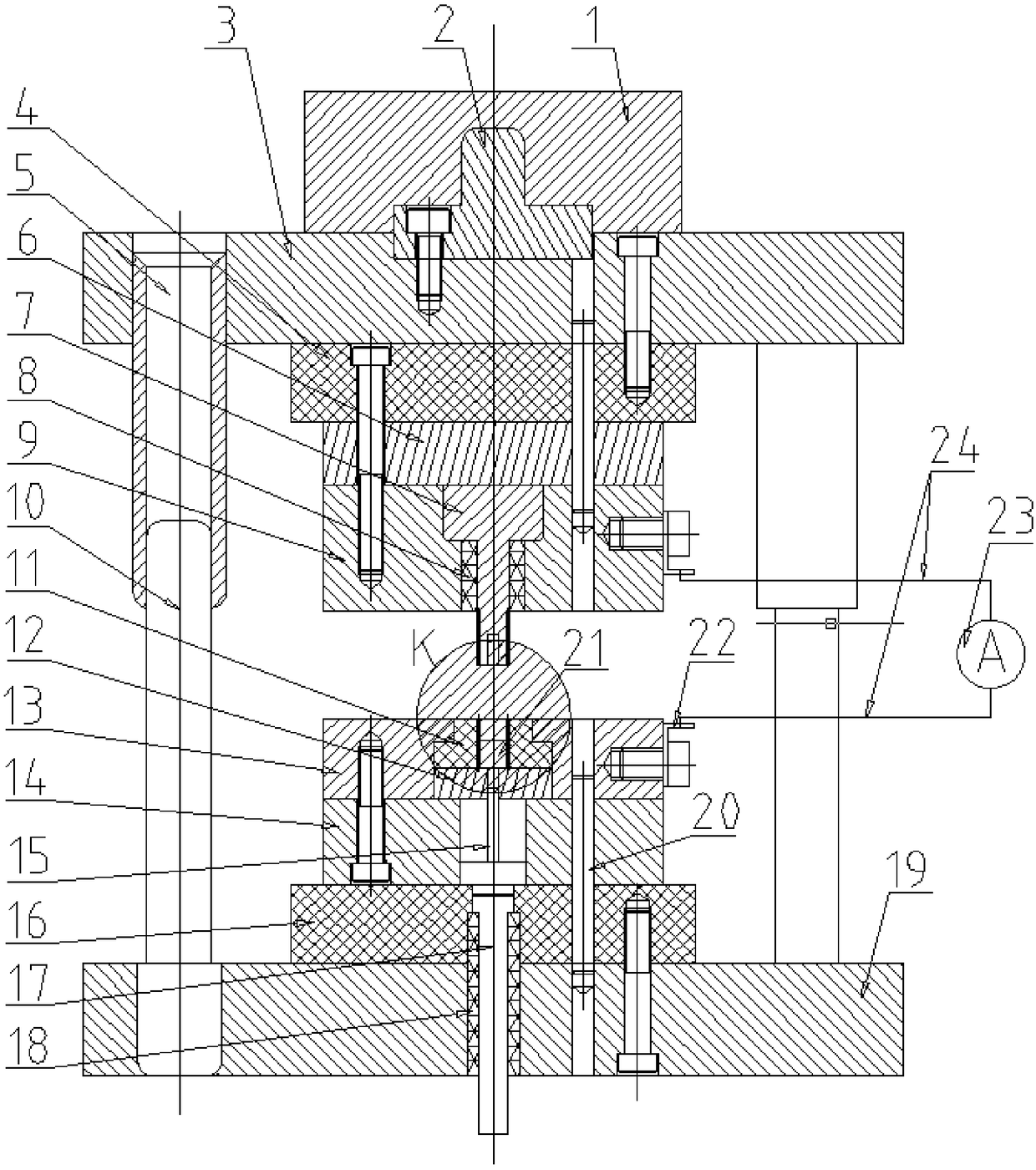

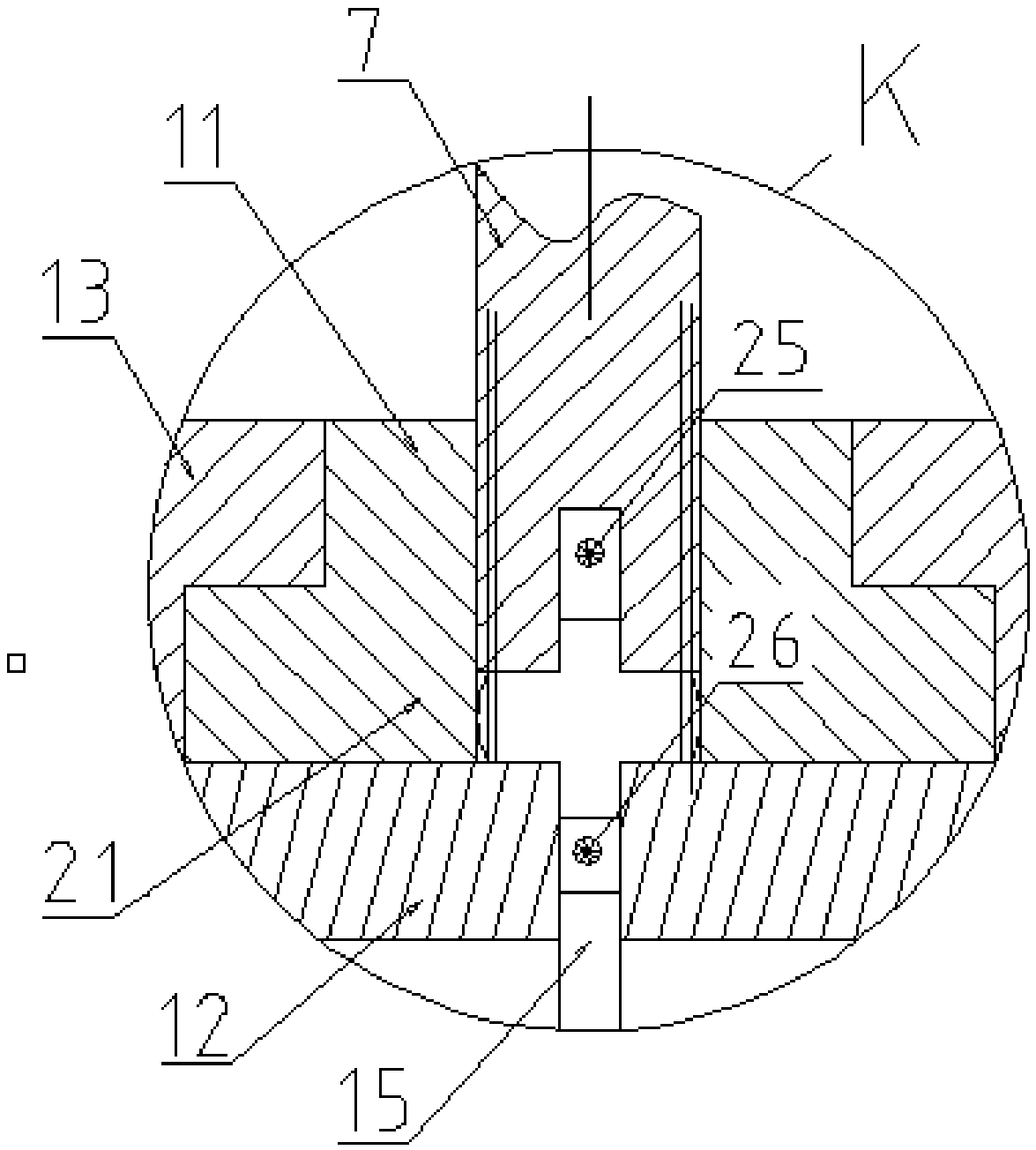

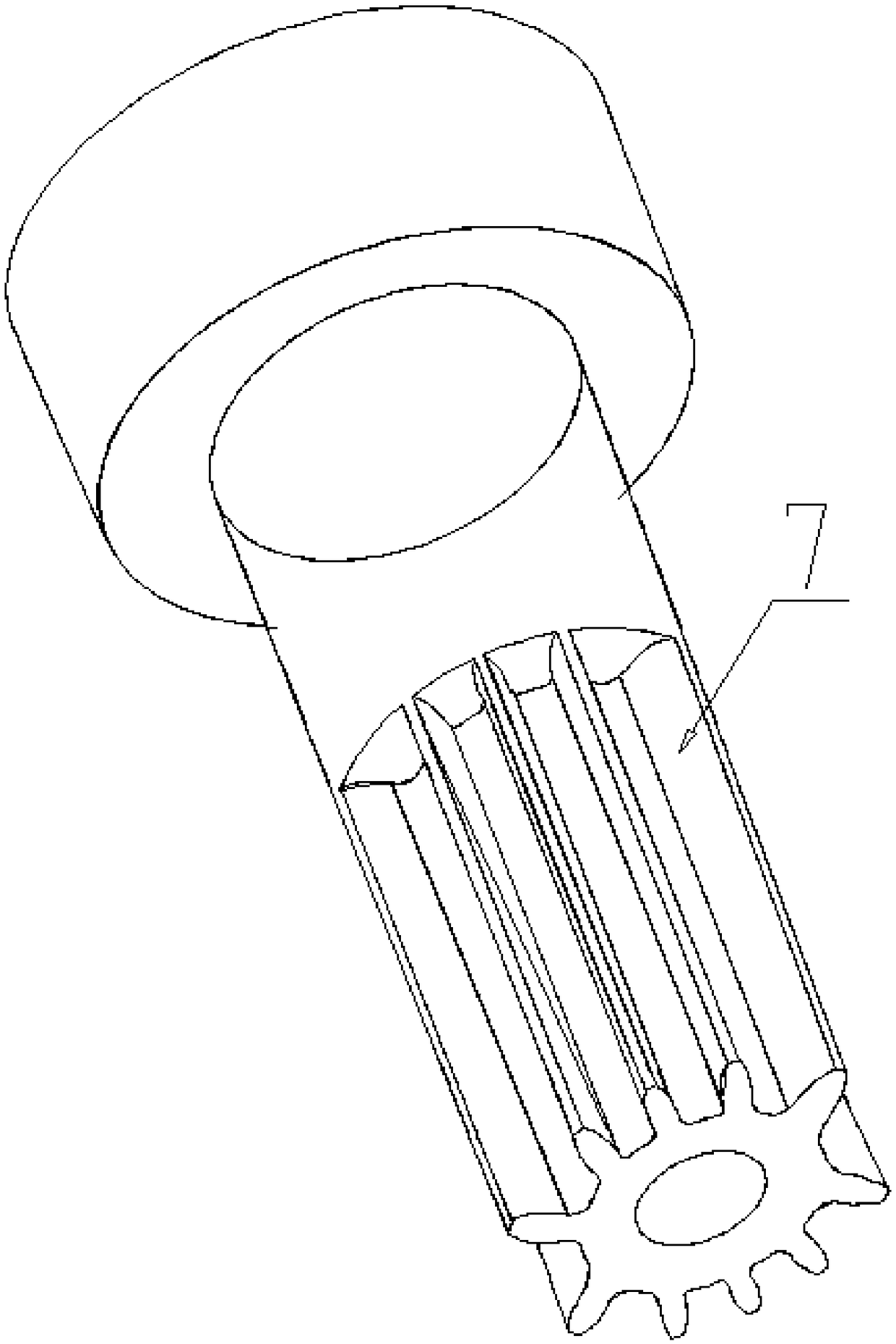

[0020] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, the titanium alloy micro-gear pulse current assisted micro-forming mold in this embodiment includes a mold part and a power supply part, and the mold part includes a mold handle 2, a punch seat 3, an upper insulating plate 4, a guide assembly, a convex mold Mold bottom plate 6, punch 7, punch protective cover 8, punch holder 9, die 11, die bottom plate 12, die fixing plate 13, die gasket 14, ejector 15, lower insulating plate 16 , lower ejector rod 17, lower ejector rod sleeve 18 and die seat 19; the top of die handle 2 is fixedly installed on the bottom end of slide block 1 in the press, and the bottom end of die handle 2 is fixed to the top of punch seat 3 Connection, the punch holder body 9 is processed with a punch installation through hole, the punch protection sleeve 8 is set on the punch 7, the punch 7 and the punch protection sleeve 8 are installed on the punch installation...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 Describe this embodiment, the titanium alloy microgear pulse current assisted micro-forming mold in this embodiment, the power supply part includes a pulse power supply 23, two electrode joints 22 and two wires 24; one electrode joint 22 is installed on the punch clamping body 9, another electrode connector 22 is installed on the outer wall of the die fixing plate 13, and each electrode connector 22 is connected with the pulse power supply 23 by a wire 24. The pulse current passes through the wire 24, the electrode joint 22, the clamping body of the punch 9, the punch 7, the titanium alloy blank 21, the die 11, the die fixing plate 13, and the die bottom plate 12 to form a power circuit to provide a pulse current to heat the titanium alloy. The alloy blank 21 ensures the smooth progress of the micro-gear extrusion, and other methods are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 Describe this embodiment, the titanium alloy micro-gear pulse current assisted micro-forming mold in this embodiment, the guide assembly includes four guide sleeves 5 and four guide posts 10, and the four guide sleeves 5 are fixedly installed on the punch seat 3, Four guide pillars 10 are installed on the die base 19, and each guide pillar 10 is slidably inserted on a guide sleeve 5 respectively, and other methods are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com