Highly efficiently energy-saving asphalt tank

A high-efficiency, energy-saving, asphalt tank technology, applied in the field of asphalt tanks, can solve problems such as large energy consumption, and achieve the effect of low energy consumption and high-efficiency heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

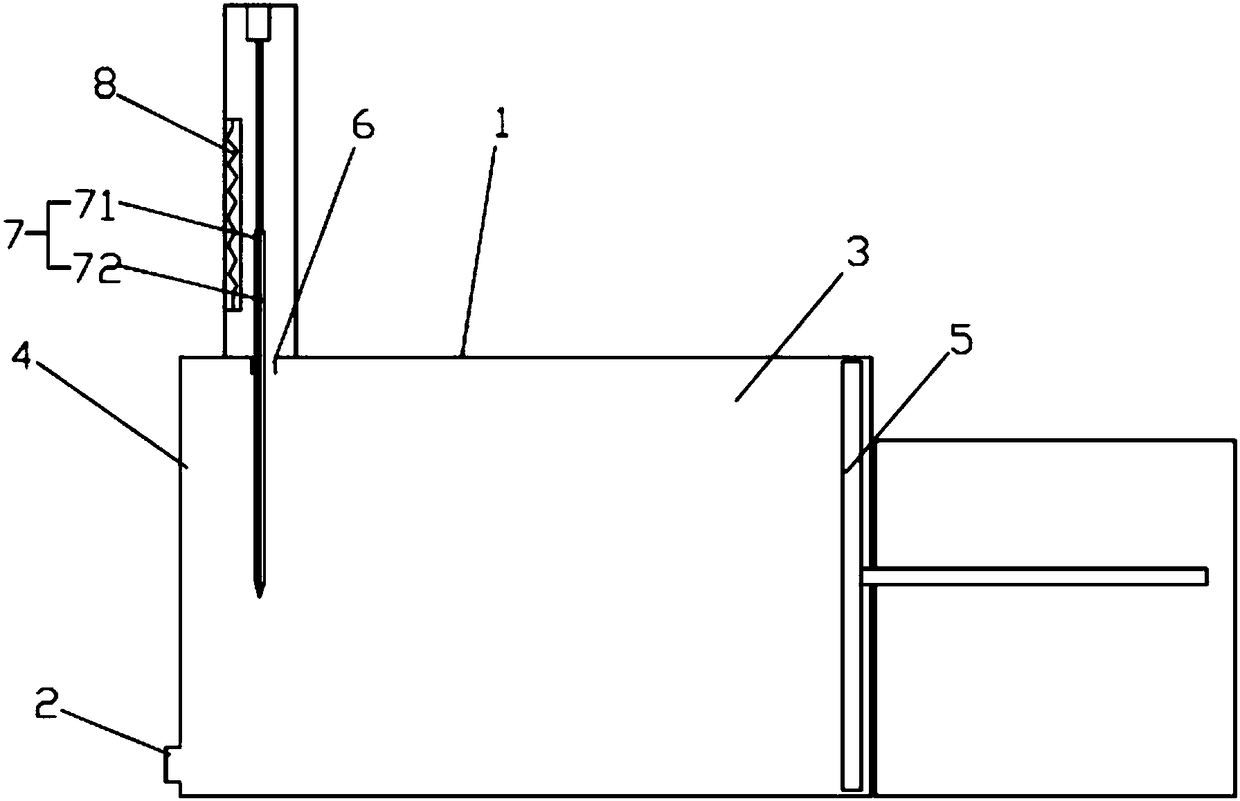

[0015] The embodiments of the high-efficiency and energy-saving asphalt tank of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] A high-efficiency and energy-saving asphalt tank, comprising a tank body 1 and a discharge port 2 arranged on the tank body 1, the discharge port 2 is disposed on the edge of the lower end of the tank body 1, the tank body 1 includes a storage part 3 and a heating part 4, A cutting device is provided between the storage part 3 and the heating part 4. The upper end of the heating part 4 is provided with an extrusion push plate 5 facing downwards in the pushing direction, and the end of the storage part 3 opposite to the heating part 4 is provided with a Feed push plate. The asphalt in the storage part 3 is in a state of normal temperature storage, and the energy consumption is low. When it is necessary to take out part of the asphalt material, the cutting device works to cut off part of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com