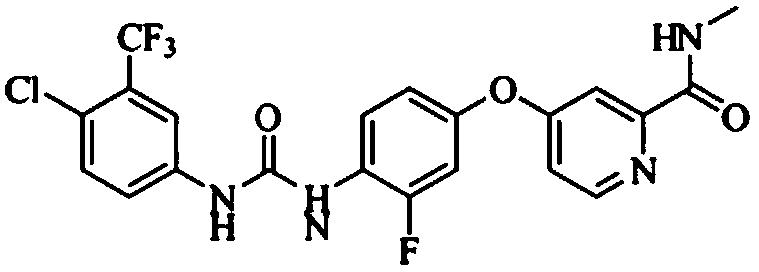

Preparation method of regorafenib

A technology of regorafenib and quantitative ratio, applied in the field of preparation of regorafenib, can solve the problems of unsuitable industrial production, expensive catalyst, difficult operation, etc., achieve high conversion rate, reduce production cost, and high reaction yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

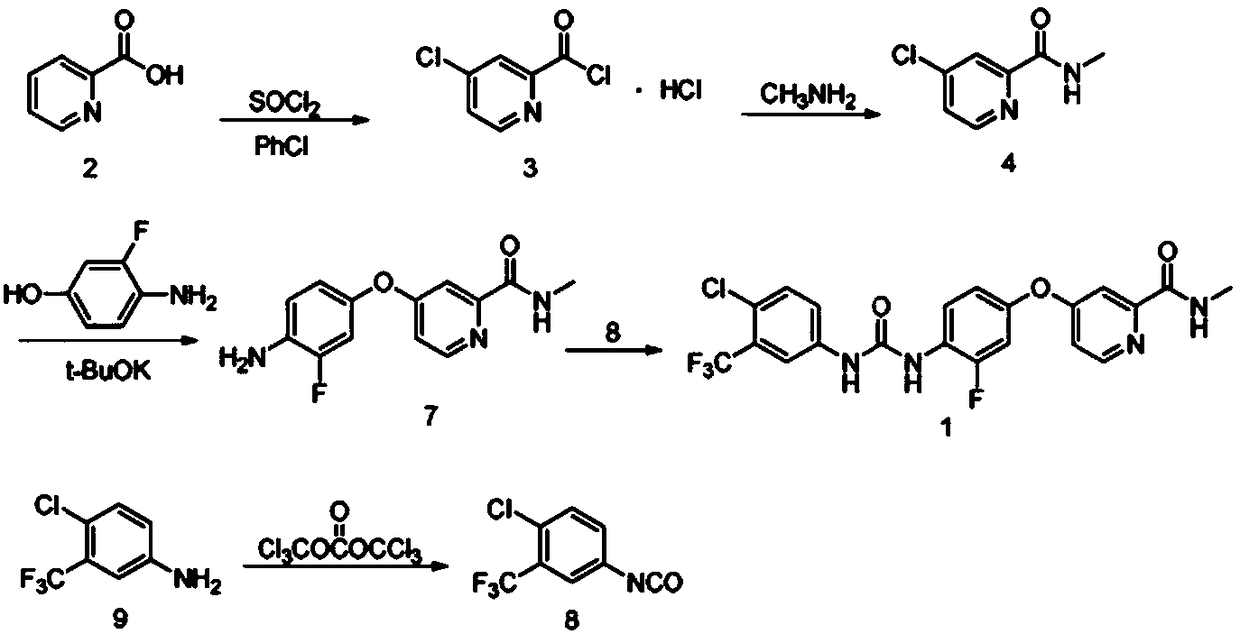

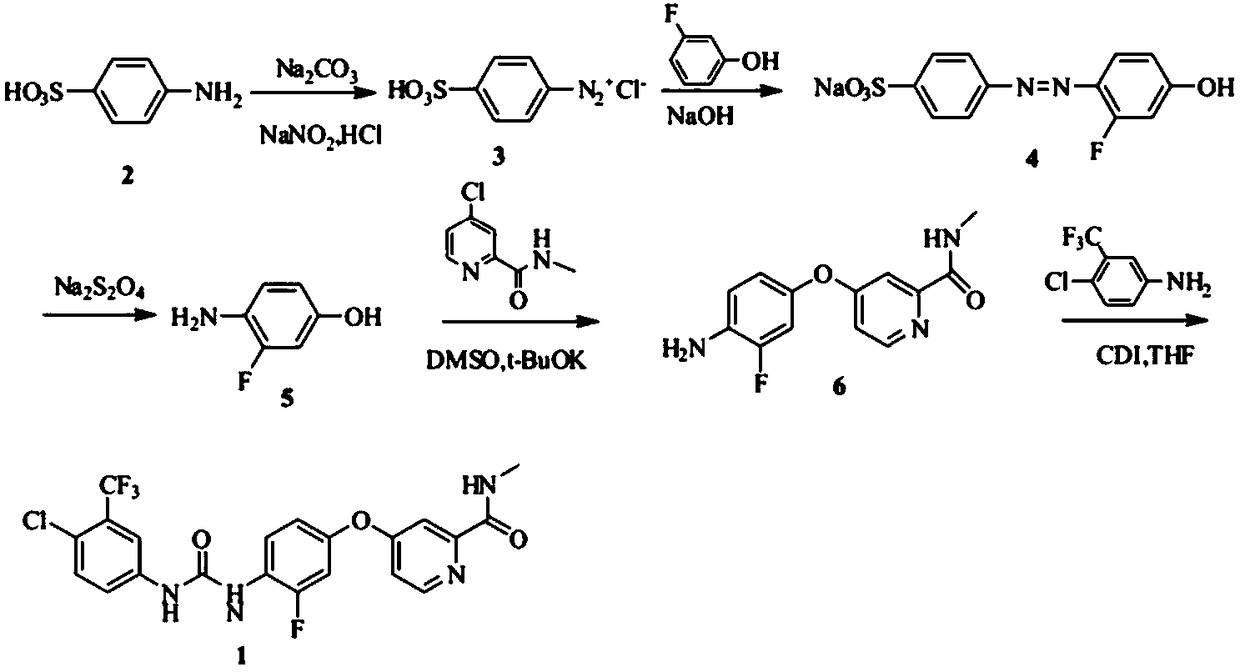

Method used

Image

Examples

Embodiment 1-1

[0024] The synthesis of embodiment 1-1 intermediate I

[0025] In a 250mL three-neck flask with a magnetic stirring device, a thermometer and a reflux condenser, add 100mmol of 4-amino-3-fluorophenol, 100mmol of anhydrous potassium carbonate, and 85mmol of 4-chloro-N-methylpyridine-2- Formamide, 2.5mmol of PEG-400 and 100mL of dichloroethane were stirred electromagnetically, and heated to reflux in a water bath for 4 hours. Cool, filter, dichloroethane was evaporated under reduced pressure with a water pump, the still liquid was extracted with 240mL ether, dried, and concentrated to obtain 21.39g of a light yellow liquid, Intermediate I, with a yield of 96.3% and a purity of 99.90%.

Embodiment 1-2

[0026] The synthesis of embodiment 1-2 intermediate I

[0027] In a 250mL three-neck flask with a magnetic stirring device, a thermometer and a reflux condenser, add 90mmol of 4-amino-3-fluorophenol, 100mmol of anhydrous potassium carbonate, and 90mmol of 4-chloro-N-methylpyridine-2- Formamide, 2mmol of PEG-400 and 100mL of dichloroethane were stirred electromagnetically, and heated to reflux in a water bath for 4 hours. Cool, filter, dichloroethane was evaporated under reduced pressure with a water pump, the still liquid was extracted with 240mL ether, dried, and concentrated to obtain 21.32g of a light yellow liquid, namely Intermediate I, with a yield of 90.6% and a purity of 99.80%.

Embodiment 1-3

[0028] Synthesis of Example 1-3 Intermediate I

[0029] In a 250mL three-neck flask with a magnetic stirring device, a thermometer and a reflux condenser, add 110mmol of 4-amino-3-fluorophenol, 100mmol of anhydrous potassium carbonate, and 80mmol of 4-chloro-N-methylpyridine-2- Formamide, 3mmol of PEG-400 and 100mL of dichloroethane were stirred electromagnetically, and heated to reflux in a water bath for 4 hours. Cool, filter, dichloroethane was evaporated under reduced pressure with a water pump, and the still liquid was extracted with 240 mL of ether, dried, and concentrated to obtain 19.59 g of a light yellow liquid, namely Intermediate I, with a yield of 93.7% and a purity of 99.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com